Device manufacturing method suitable for low-heat-conduction and electric-conduction material substrate

A technology of conductive materials and low thermal conductivity, which is applied in the field of device manufacturing of low thermal conductivity and conductive material substrates, can solve problems such as pollution, low production capacity, and poor graphics quality, and achieve the effects of simple process flow, high processing precision, and high yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

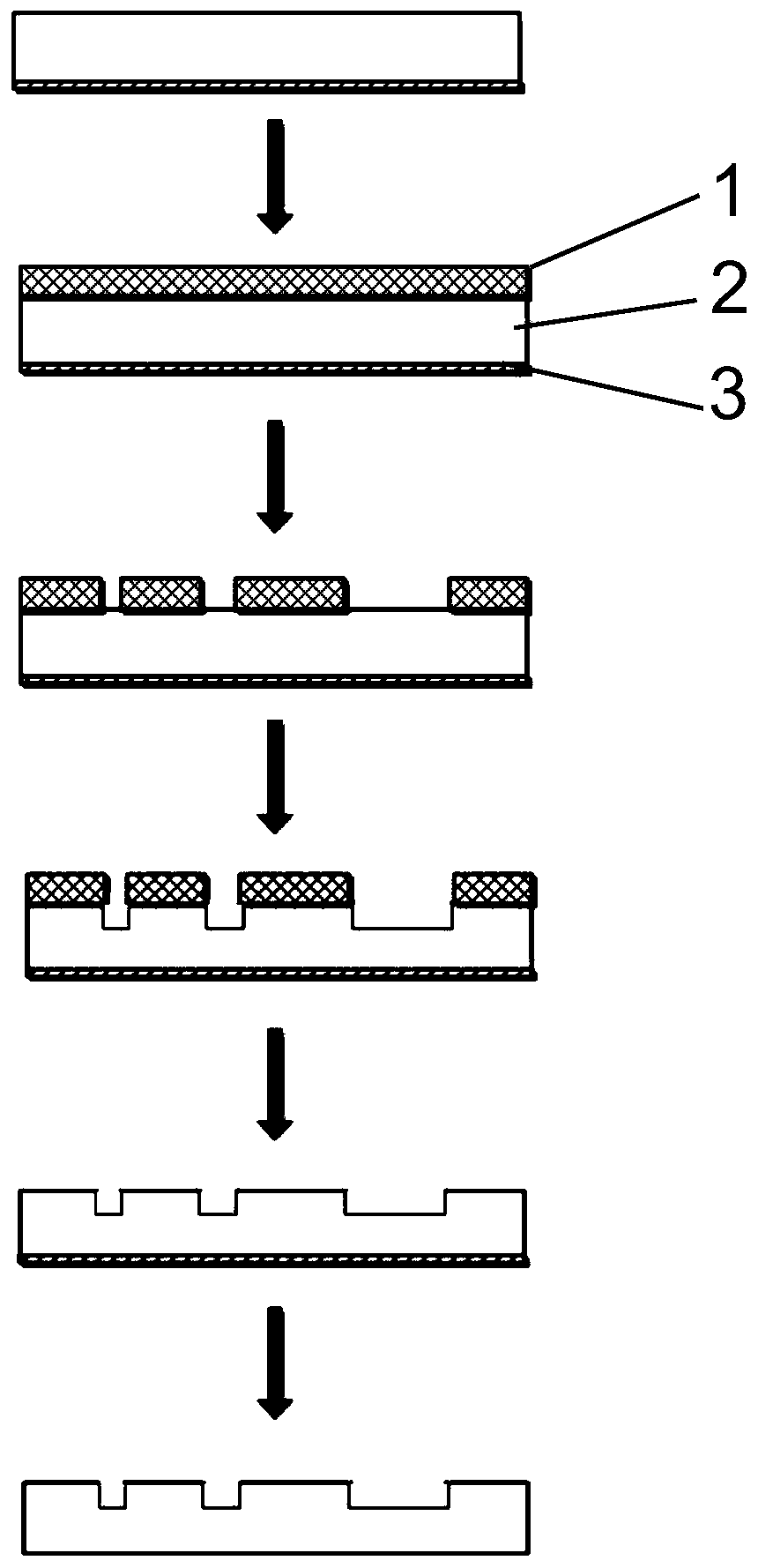

[0056] A device manufacturing method suitable for quartz glass substrates, the process is as follows figure 1 shown, including the following steps:

[0057] 1) A 1000 angstrom thick, opaque conductive film 1 (TiW) is plated on the back of the quartz glass substrate 2 by magnetron sputtering.

[0058] 2) Coating photoresist 3 on the front side of the quartz glass substrate.

[0059] 3) Exposure and development.

[0060] 4) The quartz glass substrate is dry-etched with an inductively coupled plasma dry etching equipment equipped with a unipolar electrostatic adsorption chuck to realize the replication of the graphics on the front side of the quartz glass substrate, and repeat steps 2) and 3) to achieve multi-layer graphics Replication, and complete the replication of various patterns from simple to complex, from uniform depth to multi-layer depth on the quartz glass substrate; The inert gas helium for heat dissipation.

[0061] Wherein, in step 4), the etching gas and auxili...

Embodiment 2

[0066] A method for manufacturing a device suitable for a quartz glass substrate, comprising the following steps:

[0067] 1) A 300 angstrom thick, opaque conductive TiW film was coated on the back of the quartz glass substrate by magnetron sputtering.

[0068] 2) Coating photoresist on the front side of the quartz glass substrate.

[0069] 3) Exposure and development.

[0070] 4) The quartz glass substrate is dry-etched with an inductively coupled plasma dry etching equipment equipped with a mechanical chuck to realize the replication of graphics on the front side of the quartz glass substrate, and repeat steps 2) and 3) to achieve multi-layer graphics replication, And complete the replication of various patterns on the quartz glass substrate from simple to complex, from uniform depth to multi-layer depth; Gas helium for heat dissipation.

[0071] Wherein, in step 4), the etching gas and auxiliary etching gas are selected from the following combination: CF 4 / C 4 f 8 / H...

Embodiment 3

[0076] A method for manufacturing a device suitable for a quartz glass substrate, comprising the following steps:

[0077] 1) A 500 angstrom thick, opaque conductive Cr film is plated on the back of the quartz glass substrate by evaporation process.

[0078] 2) Coating photoresist on the front side of the quartz glass substrate.

[0079] 3) Exposure and development.

[0080] 4) The quartz glass substrate is dry-etched with an inductively coupled plasma dry etching equipment equipped with a bipolar Johnsen-Rahbek type electrostatic adsorption chuck to realize the replication of the pattern on the front side of the quartz glass substrate, and repeat steps 2) and 3) To achieve multi-layer graphics replication, and complete the replication of various graphics on the quartz glass substrate from simple to complex, from uniform depth to multi-layer depth; during the etching process, it needs to be kept on the back of the chuck and the quartz glass Helium, an inert gas with small mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com