Sealing element for a sensor element of a sensor and manufacturing method thereof

A technology of sensor elements and sealing elements, applied in the field of sealing elements of sensor elements used in sensors and its manufacturing, can solve the problems of expensive, different, and problematic seals, and achieve the effect of ensuring mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

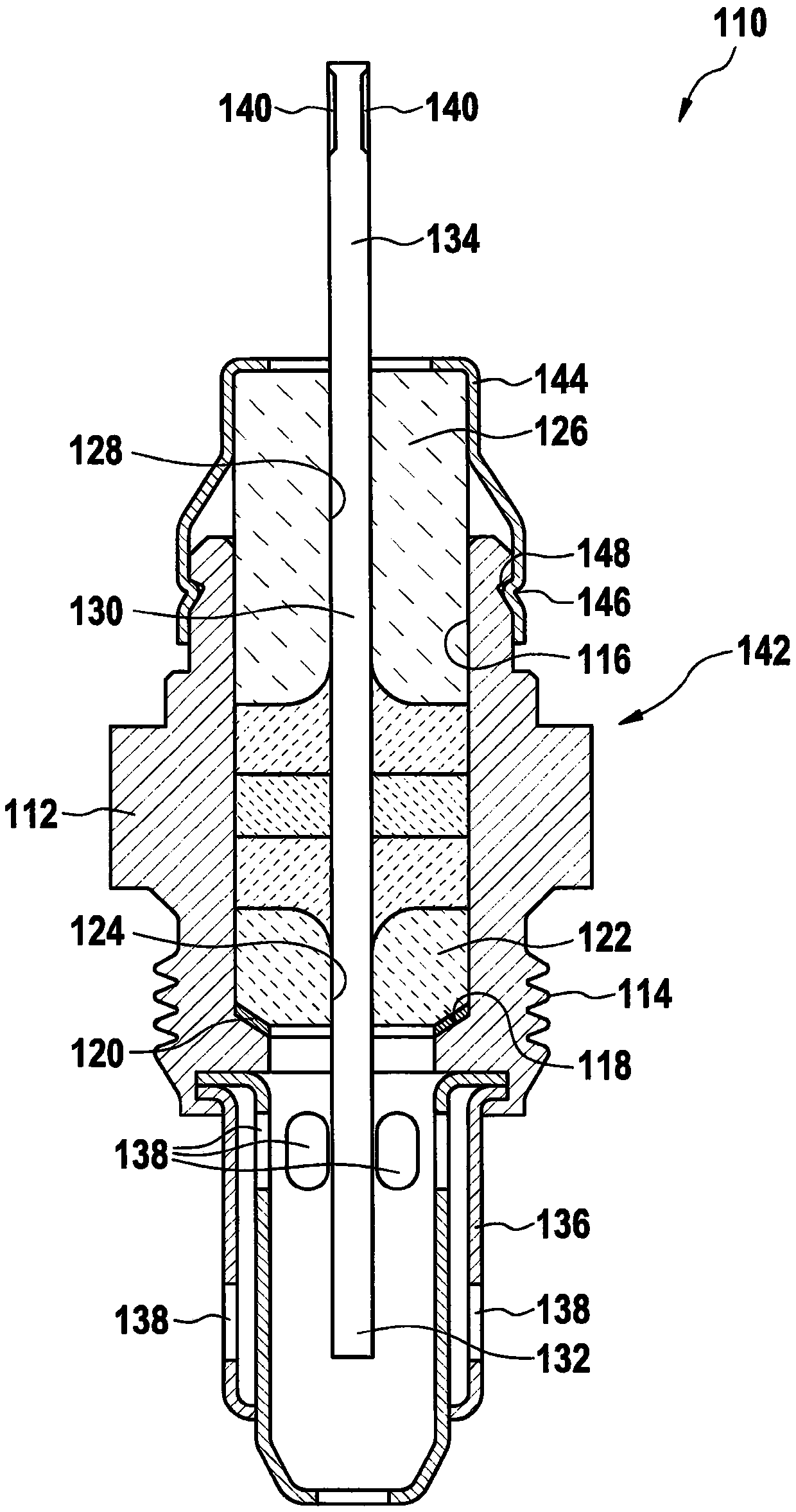

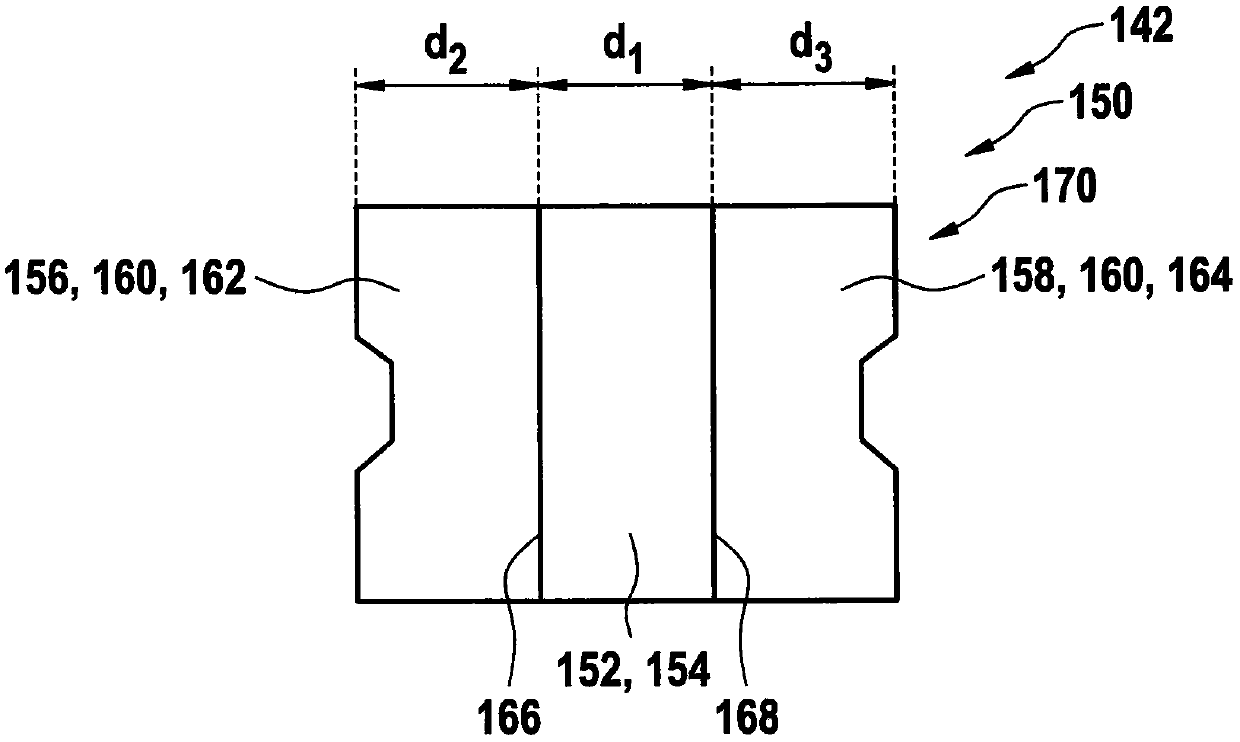

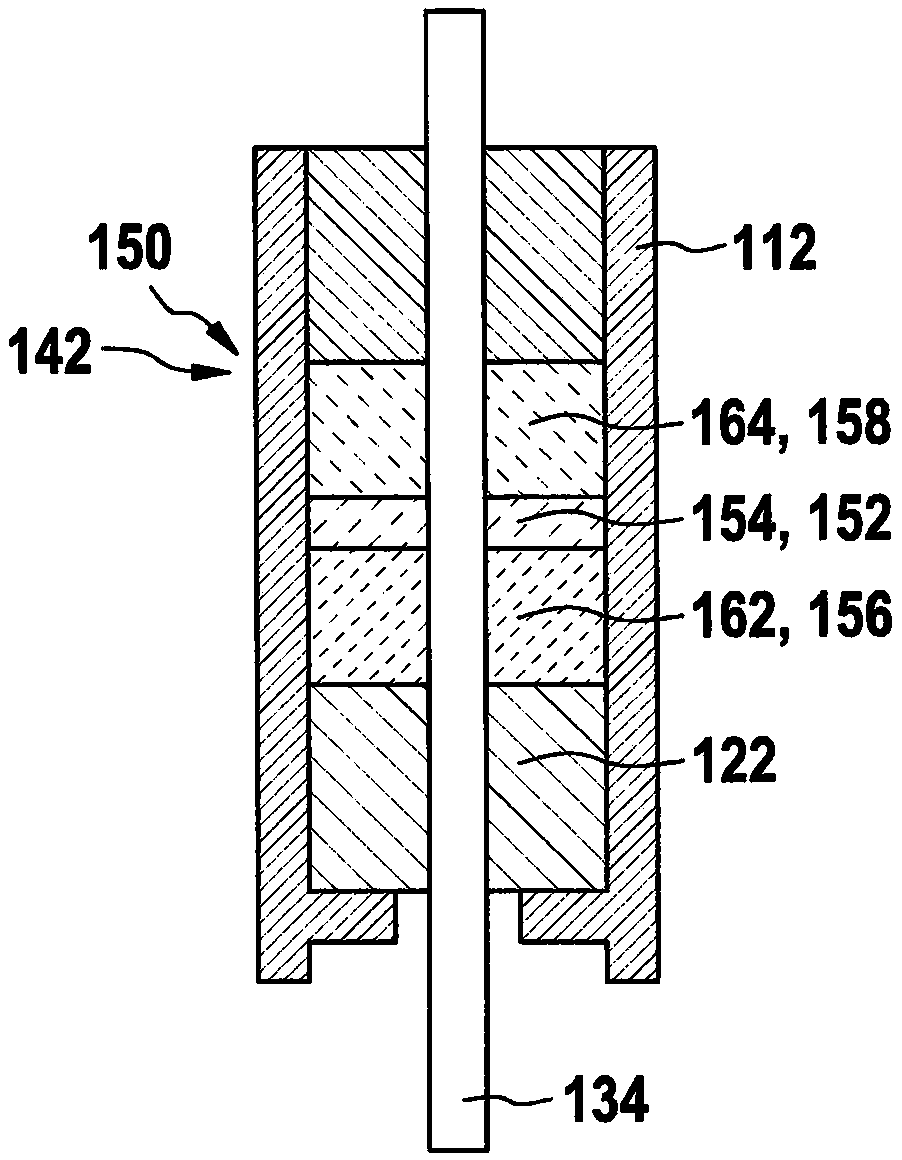

[0063] figure 1 A cross-sectional view of a sensor 110 according to the invention is shown. The sensor 110 has at least one housing 112 which may be produced from metal. The housing can have a thread 114 as a fastening means for fitting in a not-shown measuring gas line. The housing 112 has at least one longitudinal hole 116 . The longitudinal bore 116 may include a shoulder-shaped annulus 118 . On the shoulder-shaped annular surface 118 , for example, there may be a metal sealing ring 120 , on which the measuring gas-side ceramic molded part 122 rests. The measuring gas-side ceramic molded part 122 can have a continuous measuring gas-side perforation 124 extending in the direction of the longitudinal bore 116 . A further connection-side ceramic molding 126 can also be arranged in the longitudinal bore 116 at a distance from the measuring gas-side ceramic molding 122 . The joint-side ceramic molded part 126 can likewise have a centrally arranged and continuous joint-side ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com