Modified polypropylene fiber and preparing method

A technology of polypropylene fiber and polypropylene, which is applied in the direction of fiber chemical characteristics, single-component polyolefin rayon, rayon manufacturing, etc., can solve problems such as obstacles, and achieve improved compatibility, improved washability, and good The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

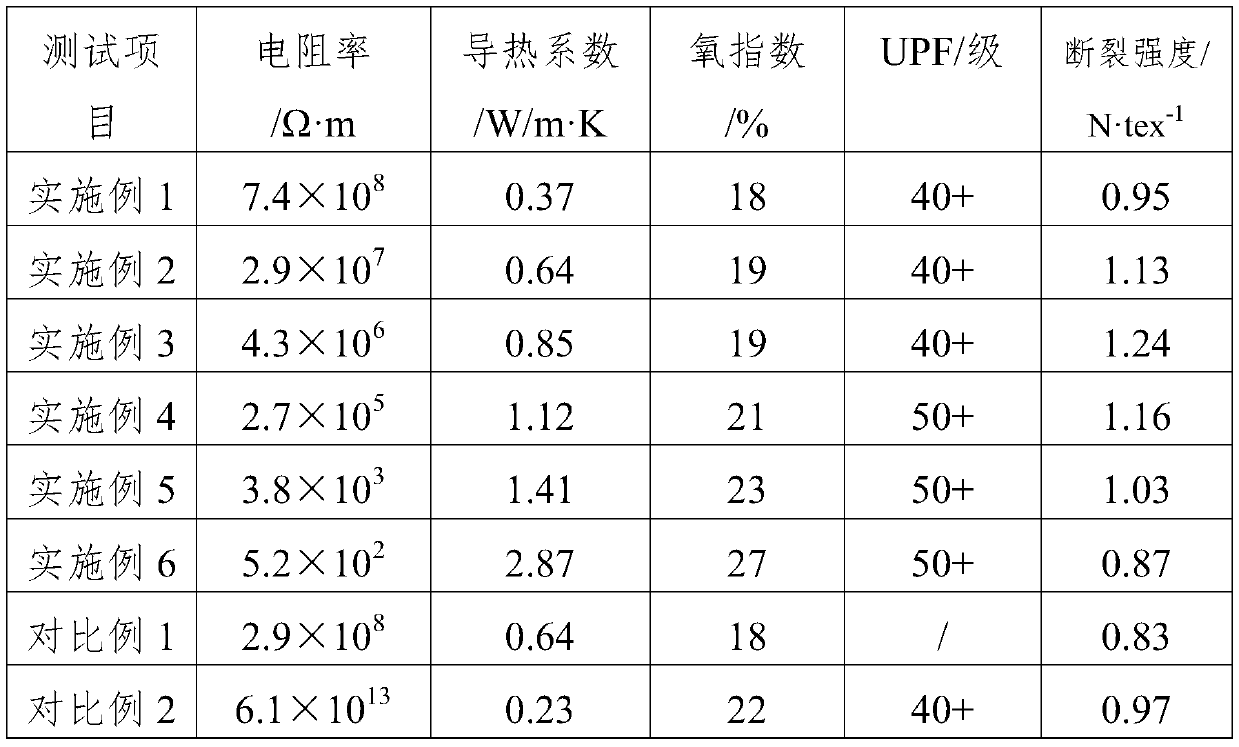

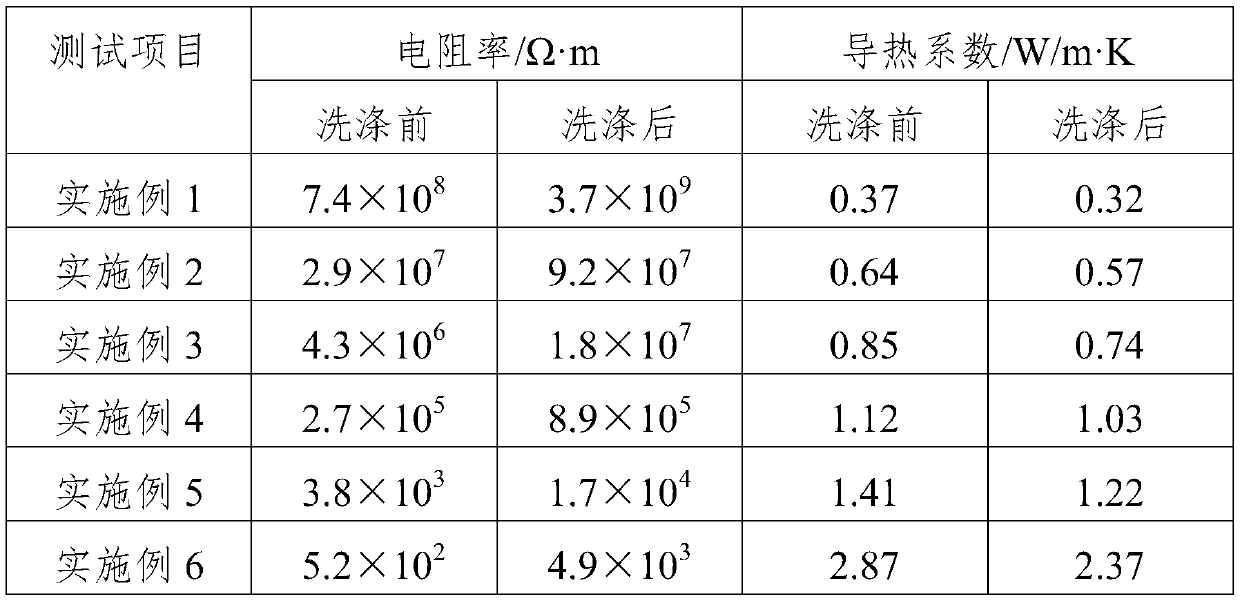

Examples

Embodiment 1

[0047] 5 parts of graphene / POSS composite material 1 and 95 parts of polypropylene particles were melted and granulated to obtain modified polypropylene masterbatch 1.

[0048] 1 part of modified polypropylene masterbatch 1 and 29 parts of polypropylene pellets were melt spun to obtain modified polypropylene fiber 1. Melt spinning process: the spinning temperature is 240°C, the draw ratio is 4, and the spinning speed is 800m / min.

Embodiment 2

[0050] 10 parts of graphene / POSS composite material 2 and 90 parts of polypropylene particles were melted and granulated to obtain modified polypropylene masterbatch 2.

[0051] 5 parts of modified polypropylene masterbatch 2 and 95 parts of polypropylene pellets were melt-spun to obtain modified polypropylene fiber 2. The melt spinning process is the same as in Example 1.

Embodiment 3

[0053] 15 parts of graphene / POSS composite material 3 and 85 parts of polypropylene particles were melted and granulated to obtain modified polypropylene masterbatch 3.

[0054] 15 parts of modified polypropylene masterbatch 3 and 85 parts of polypropylene pellets were melt spun to obtain modified polypropylene fiber 3 . The melt spinning process is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com