Water-based modified acrylic anti-corrosive coating and preparation method thereof

An anti-corrosion coating, water-based modification technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of foaming, easy to block guns, and coarse latex particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0081] 2. Preparation of protective glue:

[0082] The protective glue preparation formula is shown in Table 3. The properties of the protective glue are shown in Table 4.

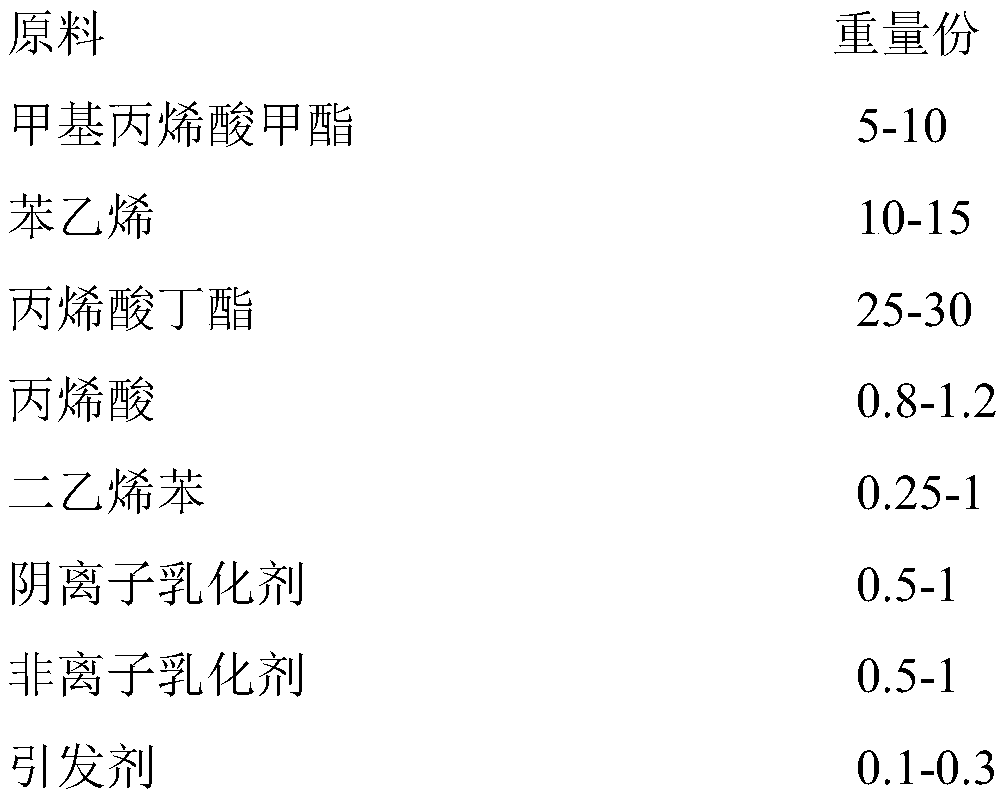

[0083] table 3

[0084]

[0085]

[0086] Its preparation process is as follows:

[0087] ①Add propylene glycol methyl ether and dipropylene glycol methyl ether into a reaction vessel equipped with a stirrer, thermometer, condenser, and dropping tank, start stirring, blow nitrogen, raise the temperature to 115-125°C, and maintain a slight boiling state;

[0088] ②Mix acrylic acid, acrylate monomers (No. 2, 4) and styrene with initiator (No. 5), enter the high-level dropping tank, and drop them into the reaction vessel under the protection of nitrogen. The dropping time is about 2-3h, after the addition, keep it warm at 115-125°C for 1-2h.

[0089] ③ Cool down to 60-70°C, add neutralizer (No. 8-9). Gradually add water and stir to obtain a copolymer carboxylate colloidal solution, which is used as...

Embodiment 12

[0109] ① Add 75 grams of propylene glycol methyl ether and 75 grams of dipropylene glycol methyl ether into the reaction vessel, start stirring, blow nitrogen, raise the temperature to 115-125 ° C, and keep a slight boiling state;

[0110] ② Add 50 grams of acrylic acid, 75 grams of maleic anhydride, 75 grams of butyl acrylate, 75 grams of styrene, 100 grams of tertiary nonanoic acid vinyl ester (VeoVa9) and 10 grams of benzoyl peroxide, mix well, and enter the high-level drop Add tank, under the protection of nitrogen, add dropwise to the reaction vessel, the dropwise adding time is about 2-3h, after adding, keep warm at 115-125°C for 1-2h.

[0111] ③ Cool down to 60-70°C, add 100 grams of dimethylethanolamine. Gradually add water and stir to obtain unsaturated carboxylic acid copolymer amine salt dispersant.

[0112] 5. Preparation of coating:

[0113] The coating formula is shown in Table 7:

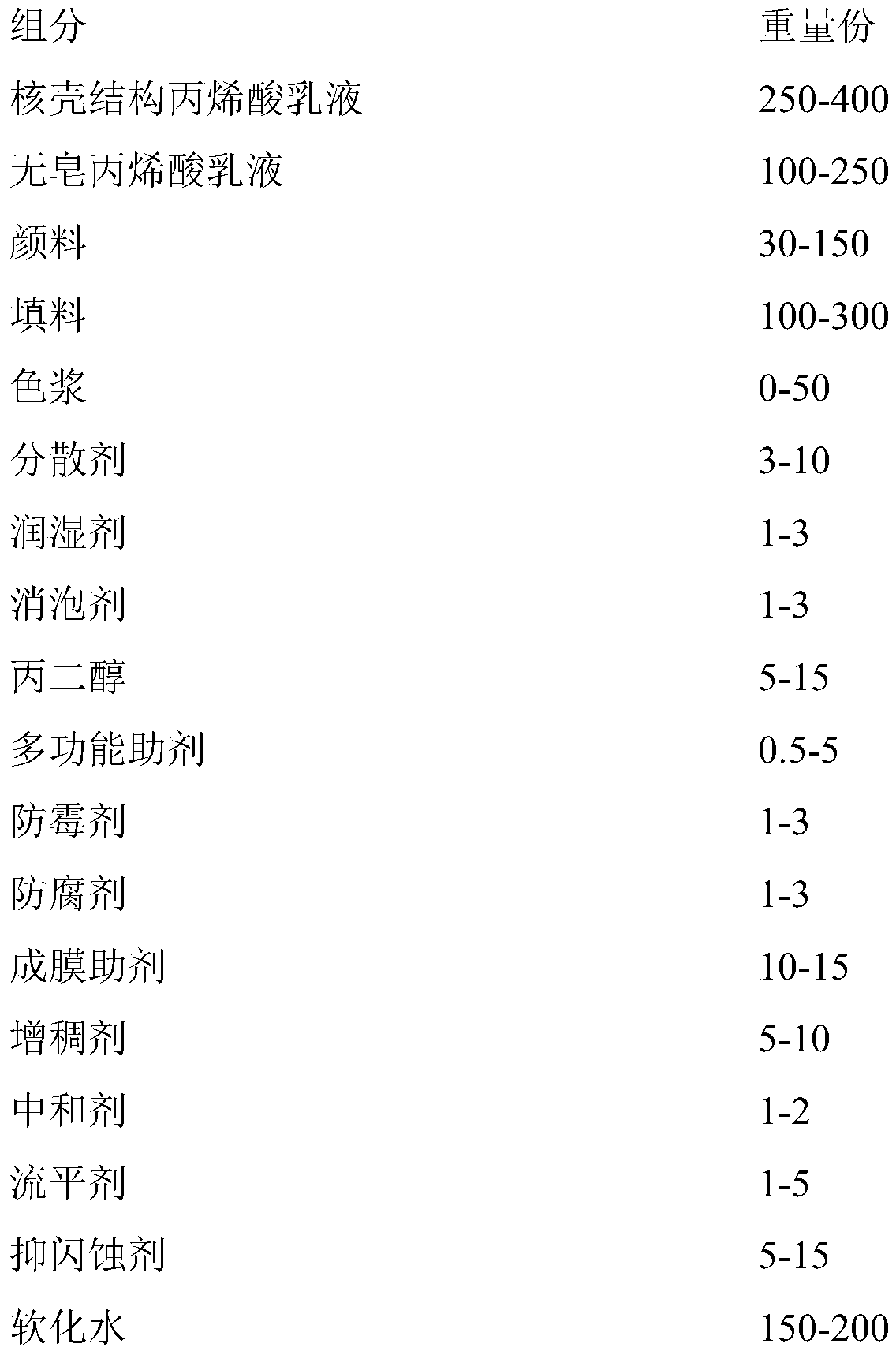

[0114] Table 7 Examples of paint formulations

[0115]

[0116] Preparatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com