Automatic weighing and distributing brick taking system of numerically controlled electric spiral brick press

A technology of automatic weighing and electric screw, which is applied in the field of brick presses, can solve the problems of affecting feeding accuracy, equipment vibration, equipment manual loading or picking, etc., to improve the uniformity of material distribution, high degree of automation, and eliminate The effect of safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

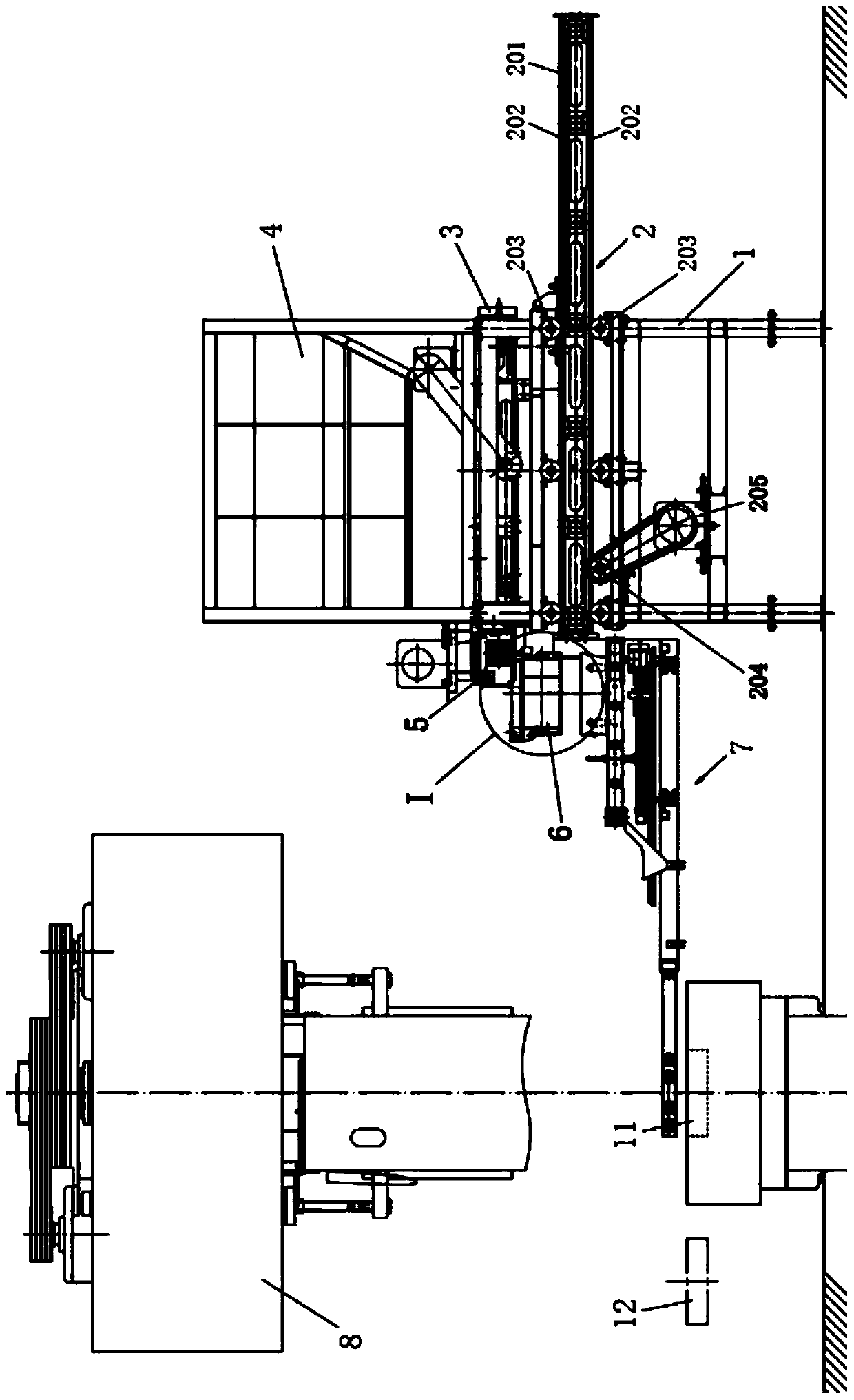

[0045] Such as Figure 1-Figure 17 As shown, the CNC electric screw press brick machine automatic weighing material distribution and brick taking system includes a frame 1, a storage device 4 is fixed on the top of the frame 1, and a belt conveyor is provided below the bottom outlet of the storage device 4 Device 3, a weighing device 6 is provided below the blanking end of the belt conveying device 3, and a cloth brick picking hand 7 is provided below the weighing device 6.

[0046] The storage device 4 includes a storage hopper 401, a stirring paddle 402 and a level gauge 403 arranged in the storage hopper 401, a gearbox 405 connected to the shaft end of the stirring paddle 402 outside the storage hopper 401, and a gearbox The motor speed reducer 406 connected to the input end of 405, the feeding limiting plate 404 located at the outlet of the bottom of the storage hopper 401, the feeding limiting plate 404 is close to the forward direction side of the belt conveyor 3, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com