Wood bamboo material with super-hydrophobic mildew-proof anticorrosive coating and preparation method thereof

An anti-corrosion coating, super-hydrophobic technology, applied in wood treatment, wood impregnation, wood impregnation, etc., can solve the problem of not realizing super-hydrophobic mildew and anti-corrosion at the same time, reduce the degree of microbial erosion, reduce the cost of chemicals, equipment requirements low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1. Preparation: air-dry the moso bamboo slices (50mm*20mm*5mm) to a moisture content of 10%, and seal them for later use; prepare 2% sodium methyl silicate solution and 2% cupric chloride solution respectively, and then stir them in a mechanical In the state, titrate the methyl silicate solution with copper chloride solution to pH 10, stop the titration and continue stirring for 5 minutes to obtain a suspension; in the state of stirring, completely immerse the air-dried Moso bamboo slices in the suspension, The immersion time was 4 hours, and finally the moso bamboo slices were dried at 105° C. for 2 hours to obtain moso bamboo slices with a superhydrophobic anti-mold and anti-corrosion coating.

[0038] 2. Performance test: the water contact angle of the modified moso bamboo slices is 151.1°, the anti-mold test (ASTM D3273-00) has an anti-mold grade of 0, and the anti-corrosion test (BS EN 113-1996) has a control effect of 100%.

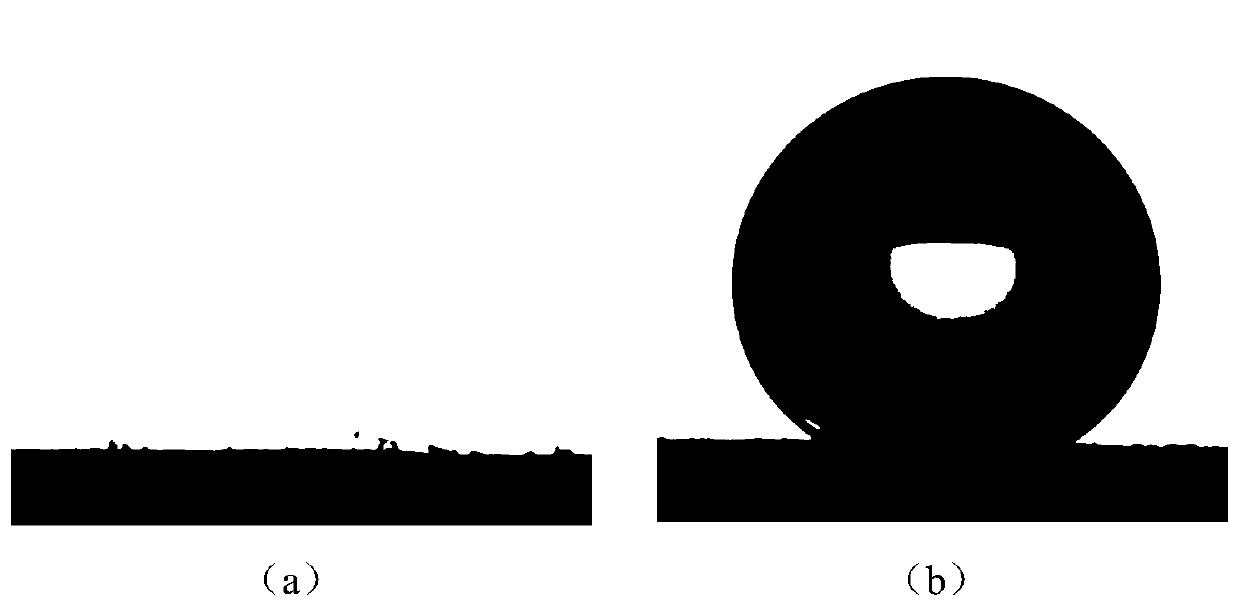

[0039] figure 1 It is the photo of th...

Embodiment 2

[0041] 1. Preparation: air-dry the rubber wood chips (50mm*20mm*5mm) until the moisture content is 11%, and seal them for later use; prepare 3% sodium methyl silicate solution and 3% cupric chloride solution respectively, and then stir them mechanically In the state, titrate the methyl silicate solution with copper chloride solution to pH 11, stop the titration and continue to stir for 5 minutes to obtain a suspension; in the state of stirring, completely immerse the air-dried rubber wood chips in the suspension, The immersion time was 5 hours, and finally the rubber wood chips were dried at 105° C. for 2.5 hours to obtain rubber wood chips with a super-hydrophobic anti-mildew and anti-corrosion coating.

[0042] 2. Performance test: the water contact angle of the modified rubber wood bamboo chips is 151.8°, the anti-mold test (ASTM D3273-00) has a mildew resistance level of 0, and the anti-corrosion test (BS EN 113-1996) has a control effect of 100%.

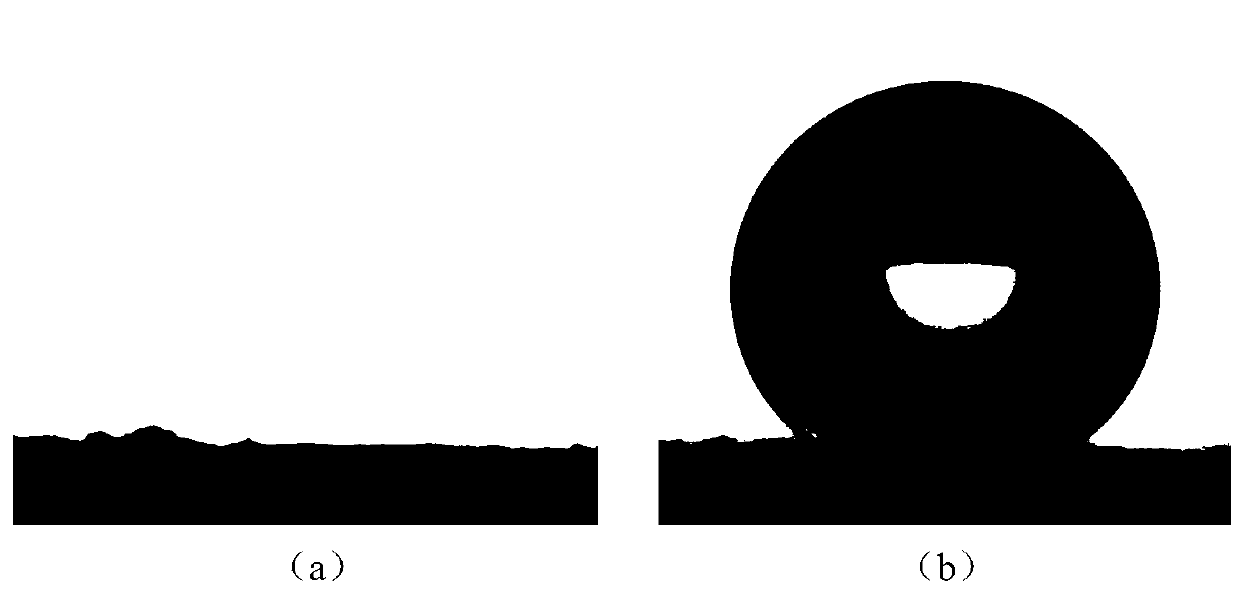

[0043] image 3 It is ...

Embodiment 3

[0045] 1. Preparation: Air-dry the moso bamboo slices (50mm*20mm*5mm) to a moisture content of 8%, and seal them for later use; prepare 0.1% sodium methyl silicate solution and 0.1% copper chloride solution respectively, and then stir them in a mechanical Under the state, titrate the methyl silicate solution with copper chloride solution to pH 9, stop the titration and continue to stir for 5 minutes to obtain a suspension; under the state of stirring, completely immerse the air-dried Moso bamboo slices in the suspension, The soaking time was 8 hours, and finally the moso bamboo slices were dried at 103° C. for 5 hours to obtain the moso bamboo slices with superhydrophobic anti-mildew and anti-corrosion coating.

[0046] 2. Performance test: the water contact angle of the modified moso bamboo slices is 134.8°, the anti-mildew test (ASTM D3273-00) grade 2, and the anti-corrosion test (BS EN 113-1996) control effect 93.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viewing angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com