Preparation method for wrapping surface of sheet-shaped silver powder with nano-silver particles

A technology of silver nanoparticles and nano-silver particles, applied in nanotechnology and other directions, can solve the problems of high surface activity of nano-silver powder, reduce the conductivity of paste, affect the sintering and contact of silver powder, and achieve low equipment requirements and improve the system. Compatible with dispersion, satisfying the effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

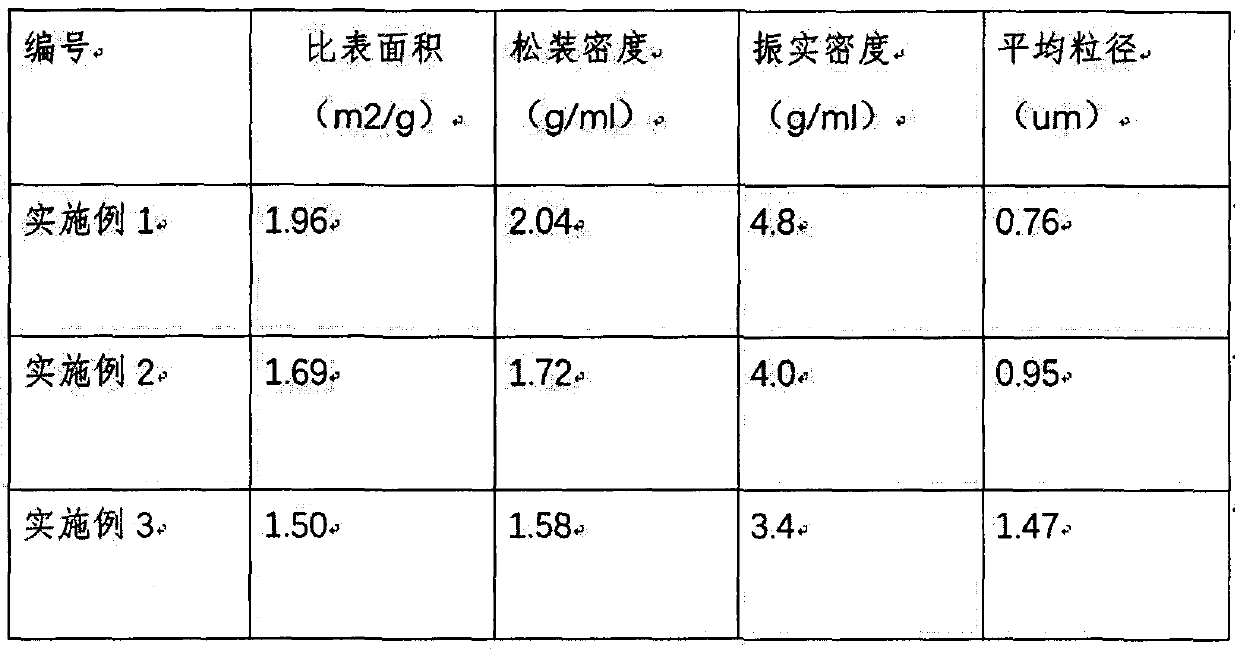

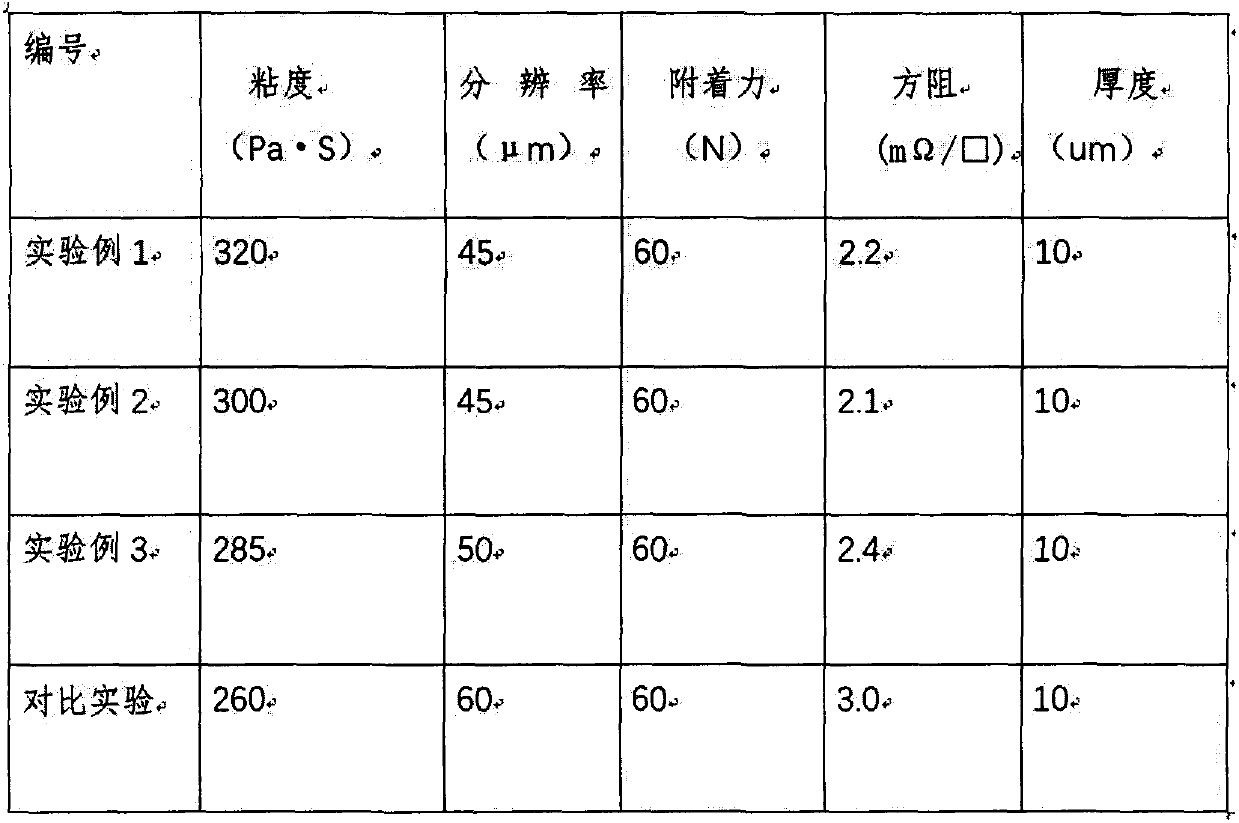

Embodiment 1

[0023] Embodiment 1: a kind of preparation method coating silver nanoparticles on the surface of flaky silver powder, concrete steps are as follows:

[0024] (1) Dissolve silver nitrate and polyacrylic acid, a water-soluble dispersant, in deionized water, prepare a solution with a silver ion concentration of 1.0 mol / L, and a temperature of 40° C., a total of 70 ml, for subsequent use;

[0025] (2) Dissolve ascorbic acid in deionized water to obtain a reducing solution with a concentration of 0.8 mol / L and a temperature of 40°C, a total of 15 ml, and set aside;

[0026] (3) The standby (1) (2) solution is injected in the tubular reactor simultaneously, adds the commercially available nitric acid (mass concentration is 65~68%) of 15ml, stirs evenly, and the prepared side length is 0.6-1.0um, Monodisperse flaky silver powder suspension solution with a thickness of 20nm;

[0027] (4) Add 10% directional nucleating agent citric acid aqueous solution of remaining silver nitrate qua...

Embodiment 2

[0029] Embodiment 2: a kind of preparation method coated with silver nanoparticles on the surface of flaky silver powder, the concrete steps are as follows:

[0030] (1) Dissolve silver nitrate and polyacrylic acid, a water-soluble dispersant, in deionized water, and configure a solution with a silver ion concentration of 1.4mol / L and a temperature of 40°C, a total of 70ml, for subsequent use;

[0031] (2) Dissolve ascorbic acid in deionized water to obtain a reducing solution with a concentration of 1.0 mol / L and a temperature of 40° C., a total of 15 ml, and set aside;

[0032] (3) The standby (1) (2) solution is injected in the tubular reactor simultaneously, adds the commercially available nitric acid (mass concentration is 65~68%) of 15ml, stirs evenly, and the prepared side length is 0.8-1.2um, Monodisperse flaky silver powder suspension solution with a thickness of 40nm;

[0033] (4) Add 10% directional nucleating agent citric acid aqueous solution of remaining silver ...

Embodiment 3

[0035] Embodiment 3: a kind of preparation method coated with silver nanoparticles on the surface of flaky silver powder, the specific steps are as follows:

[0036] (1) Dissolve silver nitrate and polyacrylic acid, a water-soluble dispersant, in deionized water, and configure a solution with an ion concentration of 2mol / L and a temperature of 40°C, a total of 70ml, for subsequent use;

[0037] (2) Dissolve ascorbic acid in deionized water to obtain a reducing solution with a concentration of 0.8 mol / L and a temperature of 40°C, a total of 15 ml, and set aside;

[0038] (3) (1), (2) solution, inject in the tubular reactor simultaneously, add the commercially available nitric acid (mass concentration is 65~68%) of 15ml, stir evenly, preparation side length is 1.2-1.6 micron, thickness 50nm monodisperse flaky silver powder suspension solution;

[0039] (4) Add 10% directional nucleating agent citric acid aqueous solution of remaining silver nitrate quality in the silver powder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com