Hippophae rhamnoides yogurt and preparation method thereof

A technology of sea buckthorn and yogurt, applied in the directions of milk preparations, dairy products, applications, etc., can solve the problems of the special flavor of yogurt, the adverse effect of yogurt, reduce the original function of yogurt, the loss of active ingredients and vitamins, and increase the number of intestinal bifidobacteria. Active, protect and accelerate the repair of gastric mucosa, the effect of promoting the absorption of nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018]Example 1, the seabuckthorn yoghurt is obtained according to the following preparation method: the first step is to select the seabuckthorn fruit, remove the non-edible parts, wash, disinfect with a disinfectant solution, and wash it twice with pure water in a sterile environment. Then beating by beating equipment to obtain seabuckthorn pulp, vacuum freeze-drying by vacuum freeze-drying equipment, so that the moisture is controlled at a mass fraction of 3.0% to 5.0%, and then powdered by beating equipment to obtain seabuckthorn whole fruit freeze-dried powder; the second step , weigh the required amount of organic raw milk, pass the inspection according to the GB19301-2010 raw milk food safety national standard, after cleaning the milk through a disc separator, refrigerate it at 2 degrees Celsius to 6 degrees Celsius for later use, take 100 kg of milk Heating to 70 degrees Celsius to obtain hot milk, adding 60 kilograms of sucrose to the hot milk, and constant volume with...

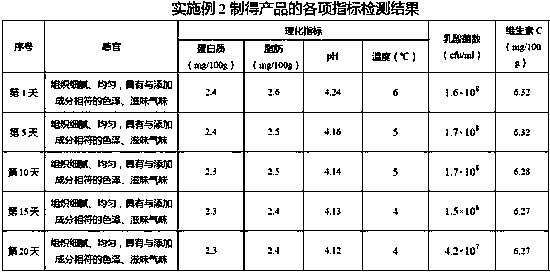

Embodiment 2

[0019] Example 2, the seabuckthorn yoghurt is obtained according to the following preparation method: first step, the seabuckthorn fruit is selected, the non-edible parts are removed, washed, sterilized with a disinfectant solution, and washed twice with pure water in a sterile environment, Then beating by beating equipment to obtain seabuckthorn pulp, vacuum freeze-drying by vacuum freeze-drying equipment, so that the moisture is controlled at a mass fraction of 3.0% to 5.0%, and then powdered by beating equipment to obtain seabuckthorn whole fruit freeze-dried powder; the second step After weighing and inspecting the required amount of organic raw milk, after cleaning the milk through a disc separator, refrigerate it at 2°C to 6°C for later use, take 150 kg of milk and heat it to 70°C to obtain hot milk, and 72 kg of Add sucrose to the hot milk, and use milk with a temperature of 2°C to 6°C to constant volume to obtain 992 kg of mixed solution, which is homogenized and steril...

Embodiment 3

[0020] Example 3, the seabuckthorn yoghurt is obtained according to the following preparation method: first step, the seabuckthorn fruit is selected, the non-edible parts are removed, cleaned, sterilized with a disinfectant solution, and washed twice with pure water in a sterile environment, Then beating by beating equipment to obtain seabuckthorn pulp, vacuum freeze-drying by vacuum freeze-drying equipment, so that the moisture is controlled at a mass fraction of 3.0% to 5.0%, and then powdered by beating equipment to obtain seabuckthorn whole fruit freeze-dried powder; the second step , after weighing and inspecting the required amount of organic raw milk, after cleaning the milk through a disc separator, refrigerate it at 2°C to 6°C for later use, take 200 kg of milk and heat it to 75°C to obtain hot milk, and 80 kg of Add sucrose into the hot milk, and use milk with a temperature of 2 to 6 degrees Celsius to make up volume to obtain 990 kg of mixed solution, homogenize and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com