Novel expanding clamping type gapless plum blossom bearing bush

A clearance-free, clip-up technology, applied in the direction of bearing components, shafts and bearings, rigid brackets of bearing components, etc., can solve the problem of uneven rotation load of driving motor and driven components, affecting the accuracy of high-precision processing equipment and other problems, to achieve the effect of low manufacturing complexity, novel structure, and elimination of dimensional errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following describes the present invention through specific implementation cases shown in the drawings. However, these descriptions are only an example, and are not intended to limit the scope and limitations of the present invention. In addition, in the following description, descriptions of well-known structures and technologies are omitted to avoid unnecessary obscurity or misunderstanding of the concept of the present invention.

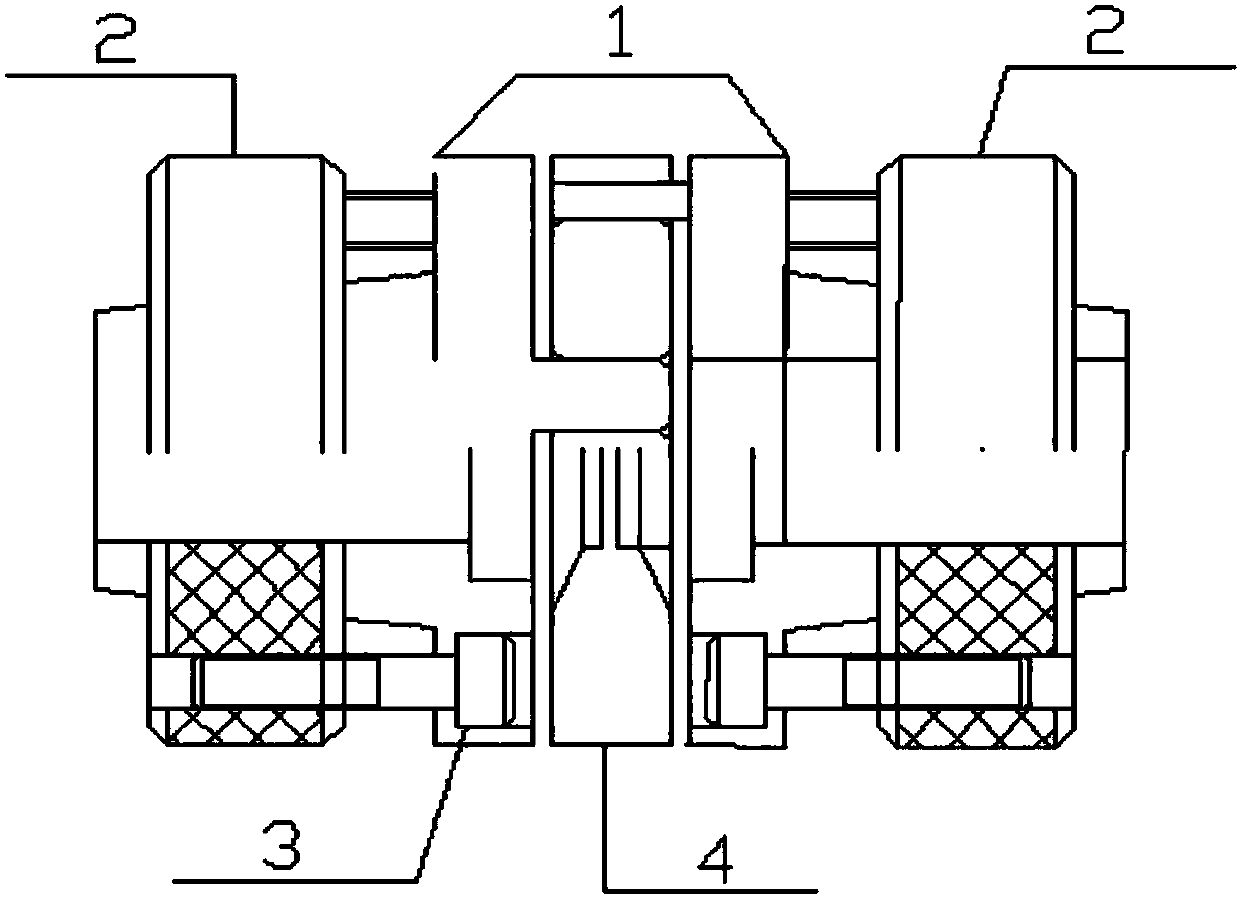

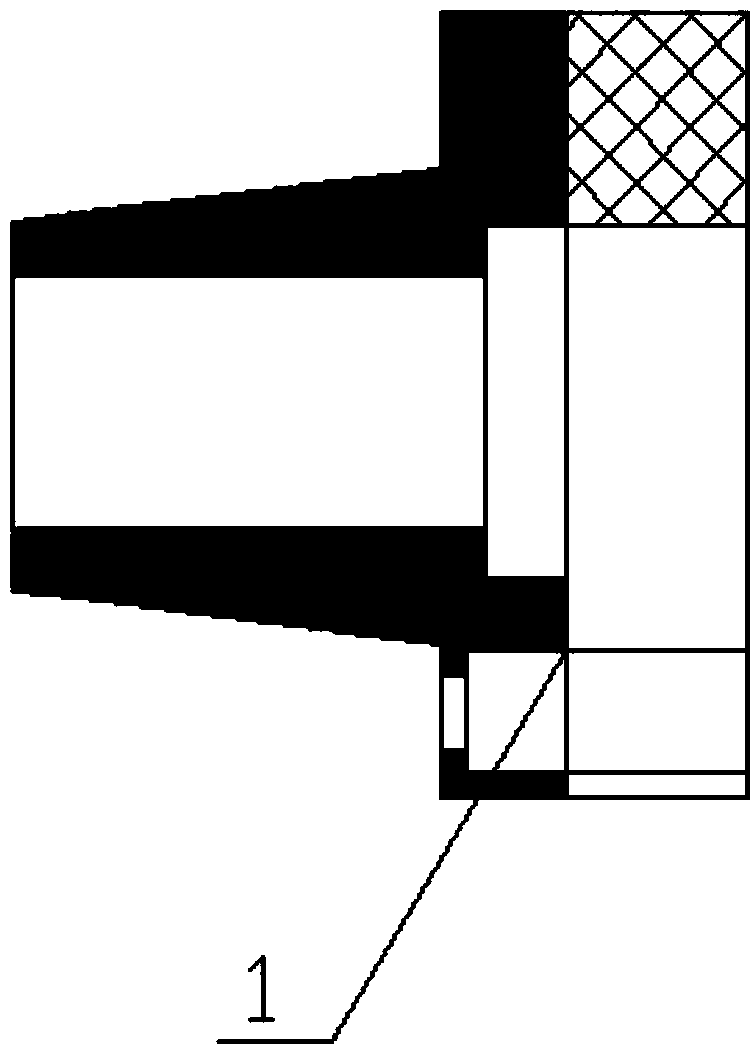

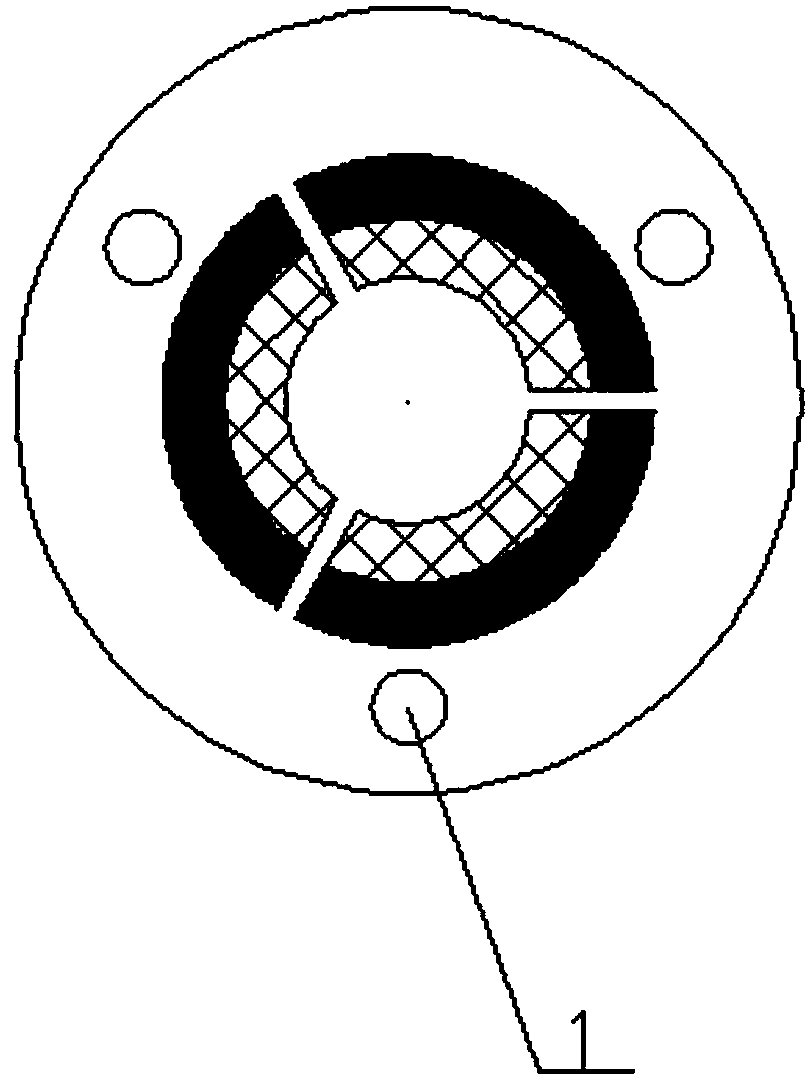

[0020] Such as figure 1 As shown in —8, this specific embodiment adopts the following technical solutions: it includes an outer taper connecting shaft 1, an inner taper sliding ring 2, a tightening adjustment screw 3, and a reinforced nylon plum elastic ring 4; the complete set of bearings includes two outer taper connecting shafts , Two inner taper sliding rings, six tightening adjustment screws, and one reinforced nylon plum elastic rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com