Biogas steam explosion fermentation system

A technology of bio-natural gas and steam explosion, which is applied in the direction of bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biomass post-treatment, etc. Problems such as gas efficiency and gas production yield can be solved to avoid a large amount of water consumption and environmental pollution, ensure consistency, and improve yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

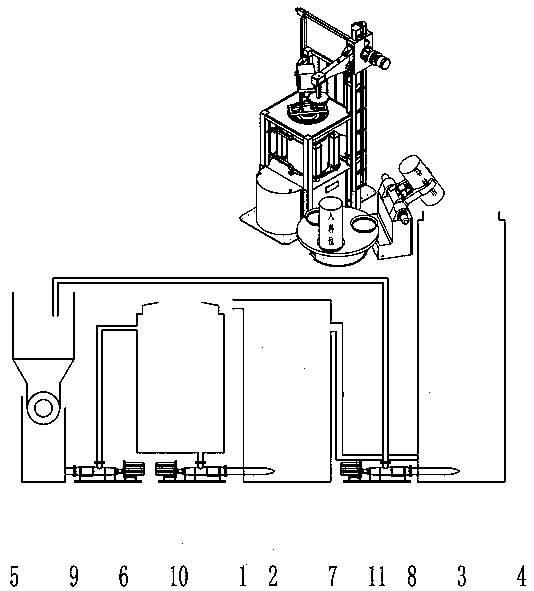

[0020] The BNG-200 type biological natural gas terminal is the concrete implementation of the above invention. This type of container station is equipped with QB-1000 steam explosion main engine and four 400 cubic meters main reactors and supporting acid hydrolysis reactors. Each feed volume is 15 tons of straw, and the daily production volume of bio-natural gas is 6000-6400 cubic meters. Realize unattended. Provides an efficient and integrated operating system template for the production of the bio-natural gas industry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com