A method for ultrasonically assisted porous ceramic brazing

A porous ceramic and ultrasonic-assisted technology, applied in the field of porous ceramic brazing, can solve the problems of low welding efficiency and low joint performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

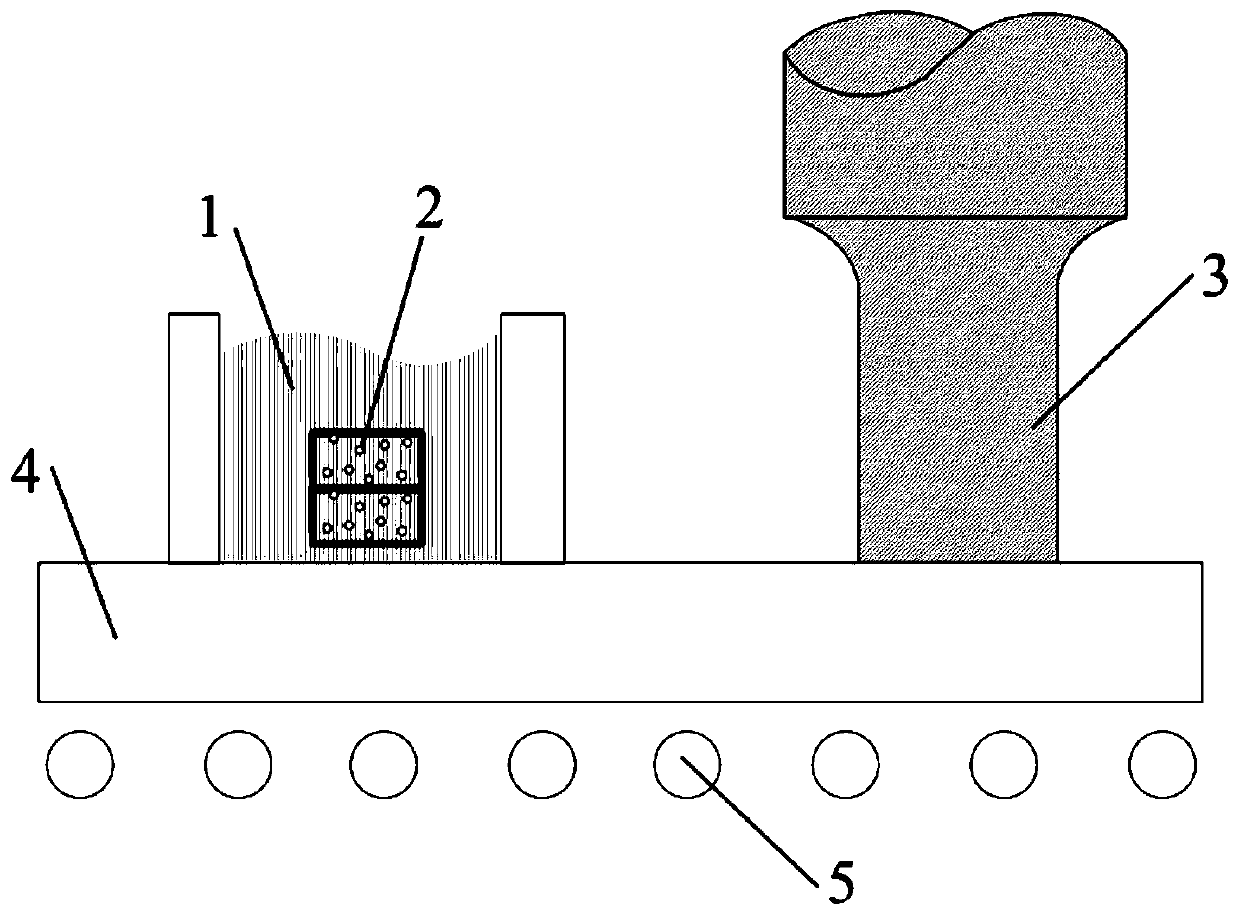

[0040] Embodiment 1: In this embodiment, a method for ultrasonically assisted porous ceramic brazing is carried out in the following steps:

[0041] 1. Pretreatment of weldments:

[0042] Clean the surfaces of 2 to 20 porous ceramics by grinding, polishing and ultrasonic cleaning to obtain pretreated porous ceramics;

[0043] The porosity of the porous ceramics is 10% to 90%;

[0044] Second, the wetting of ceramics:

[0045] Put the brazing filler metal in a brazing filler metal tank and heat it until it melts, and then, under ultrasonic vibration and the melting temperature of the brazing filler metal, immerse the pretreated porous ceramics in the molten brazing filler metal for wetting to obtain ultrasonic-assisted wetting ceramics;

[0046] When the ultrasonic vibration is continuously applied, under the condition that the ultrasonic amplitude is 0.1 μm to 100 μm, the ultrasonic frequency is 15 kHz to 50 kHz, and the ultrasonic power is 100W to 2000W, the ultrasonic wave...

specific Embodiment approach 2

[0059] Specific embodiment two: the difference between this embodiment and specific embodiment two is: the porous ceramic described in step one is Si 3 N 4 Ceramic, Si 2 N 2 O ceramics, SiC ceramics, SiBCN ceramics, ZrO 2 Ceramic, Al 2 o 3 Ceramic, TiB 2 Ceramic, B 4 Cceramics, ZrB 2 Ceramic, TaB 2 One or more of ceramics, ZrC ceramics, binary ceramics, ternary ceramics and quaternary ceramics. Others are the same as in the second embodiment.

specific Embodiment approach 3

[0060] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that when the temperature of the porous ceramic weldment described in step 3 is below 190°C, the brazing filler metal described in step 2 is Sn-based brazing filler metal ; when the service temperature of the porous ceramic weldment described in step 3 is below 380°C, the solder described in step 2 is Zn-based solder; when the service temperature of the porous ceramic weldment described in step 3 is below 600°C, Then the brazing filler metal described in step 2 is Al-based brazing filler metal. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com