A column separation device and method for mineralization-flotation separation

A flotation column and flotation technology, applied in flotation, solid separation, etc., can solve the problems of difficulty in ensuring coarse particle mineralization bubbles, low coarse particle mineralization efficiency, weak coarse particle recovery ability, etc., and achieve production and operation costs Low, significant economic benefits, the effect of reducing the probability of desorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

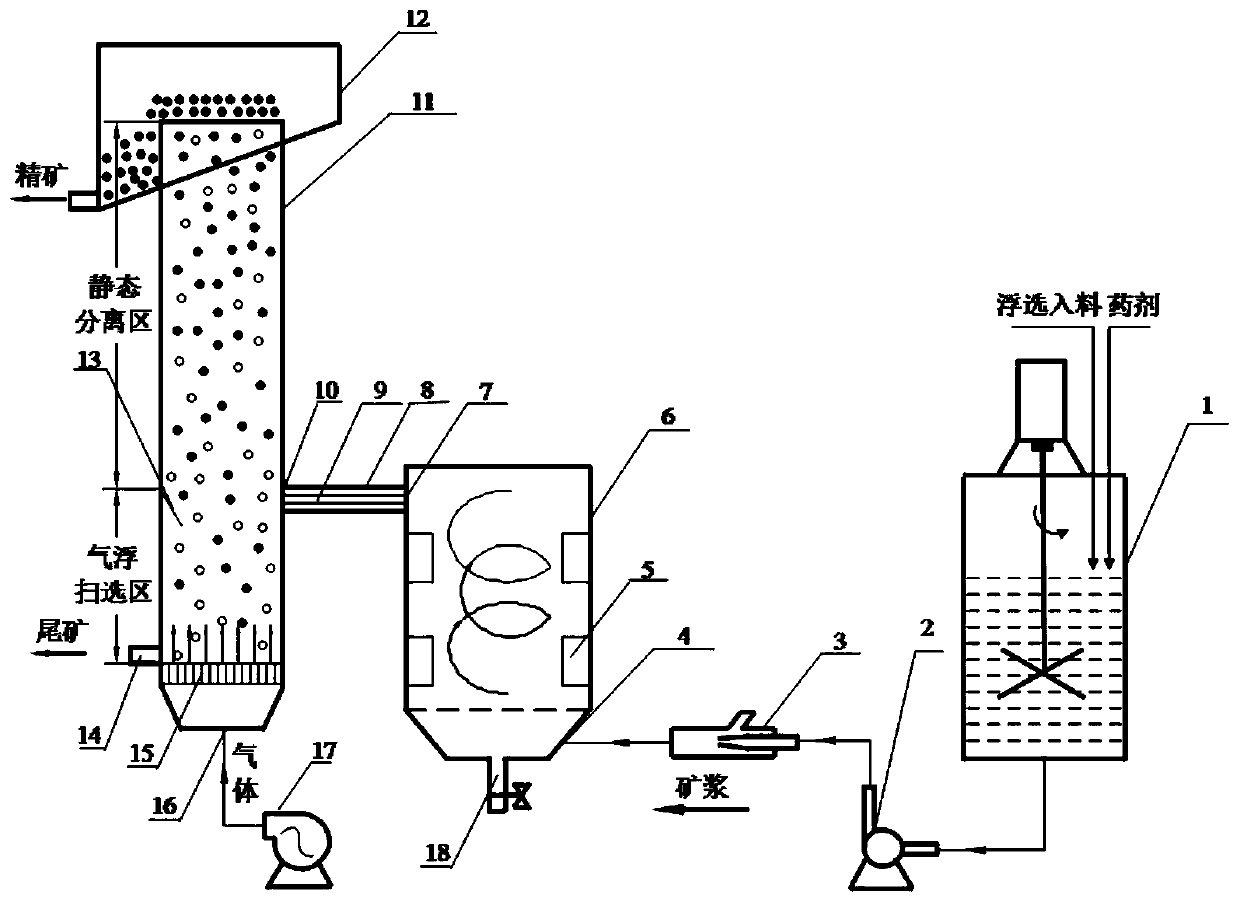

[0023] Attached below figure 1 The specific embodiments of the present invention are described in further detail:

[0024] figure 1 As shown, the column separation equipment based on mineralization-flotation separation of the present invention includes a stirring tank 1, a pump 2, a bubble generator 3, a mineralization chamber 6, a turbulence elimination pipe 8, a flotation column 11 and an air compressor 17;

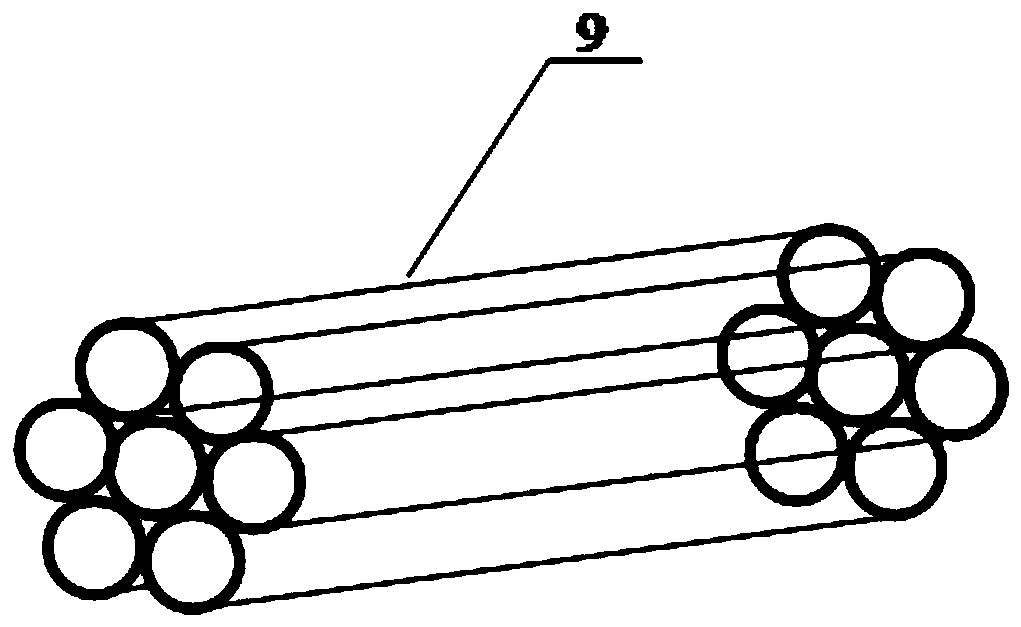

[0025] The top of the mixing bucket 1 is provided with a motor, the motor shaft extends vertically into the mixing bucket 1 and an agitator is provided, the bottom of the mixing bucket 1 is connected with the feed port of the pump 2 through a pipeline, and the discharge port of the pump 2 is connected through a pipeline Connected with the inlet of the bubble generator 3, the mineralization chamber 6 includes the upper columnar cylinder structure and the bottom of the funnel-shaped structure, the lower side of the columnar cylinder structure is provided with a feed por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com