Ammonia spraying device and method for anchoring denitrification catalyst module of coal-fired power plant

A denitration catalyst and technology for coal-fired power plants, applied in the field of flue gas denitrification, can solve the problem of uneven distribution of ammonia gas, and achieve the effects of reducing interference along the process, shortening response time, and enhancing controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment provides an ammonia injection device for an anchor paired with a denitrification catalyst module in a coal-fired power plant. figure 1 shown, from figure 1 It can be seen from the figure that it includes a denitration device, an ammonia injection grid 1 and a denitration catalyst module 2 located inside the denitration device, and the ammonia injection grid 1 is located directly above the denitration catalyst module 2;

[0028] The distance between the nozzle of the ammonia injection grid 1 and the denitration catalyst module 2 is 1-2m.

Embodiment 2

[0030] This embodiment provides an ammonia injection method for an anchor paired with a denitration catalyst module in a coal-fired power plant, wherein the method utilizes the ammonia injection device for the anchor paired with a denitration catalyst module in a coal-fired power plant provided in Example 1, which includes the following specific steps :

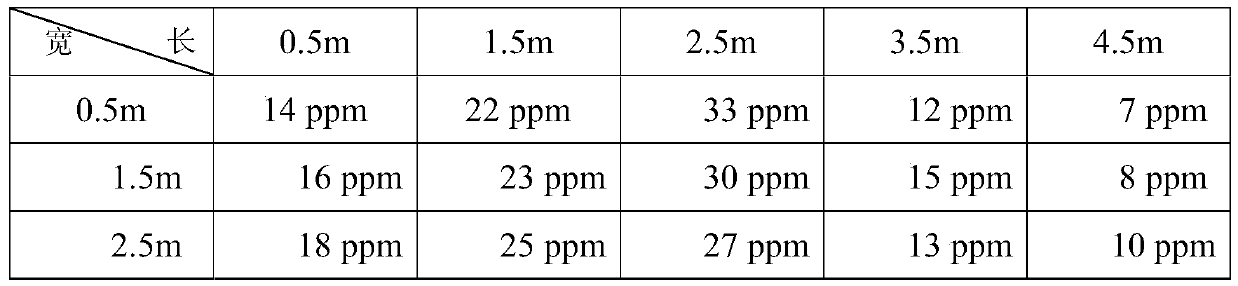

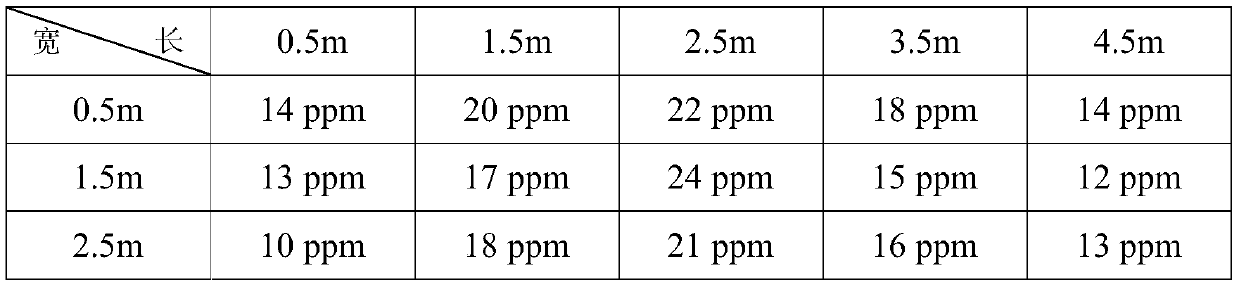

[0031] (1) Keep the valve openings of all the ammonia injection distribution pipes of the ammonia injection grid the same, and test the nitrogen oxide concentration at each grid test point at the outlet of the denitrification device by pulling the grid;

[0032] (2) adjust the valve opening of the ammonia injection distribution pipe according to the nitrogen oxide concentration distribution law of each grid test point;

[0033] Specifically include: if the concentration of nitrogen oxides at the test point is relatively high, increase the valve opening of the ammonia injection distribution pipe corresponding to the test point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com