Phase change memory and preparation method thereof

A technology of phase change memory and phase change materials, which is applied in the direction of electrical components, etc., can solve the problems of low pass rate of phase change memory products, and achieve the effects of low implementation difficulty, precise alignment, and improved product pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

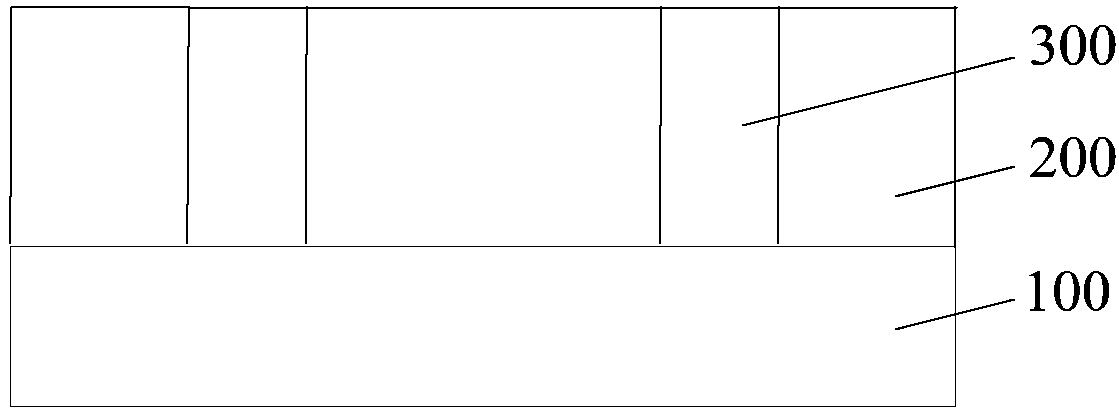

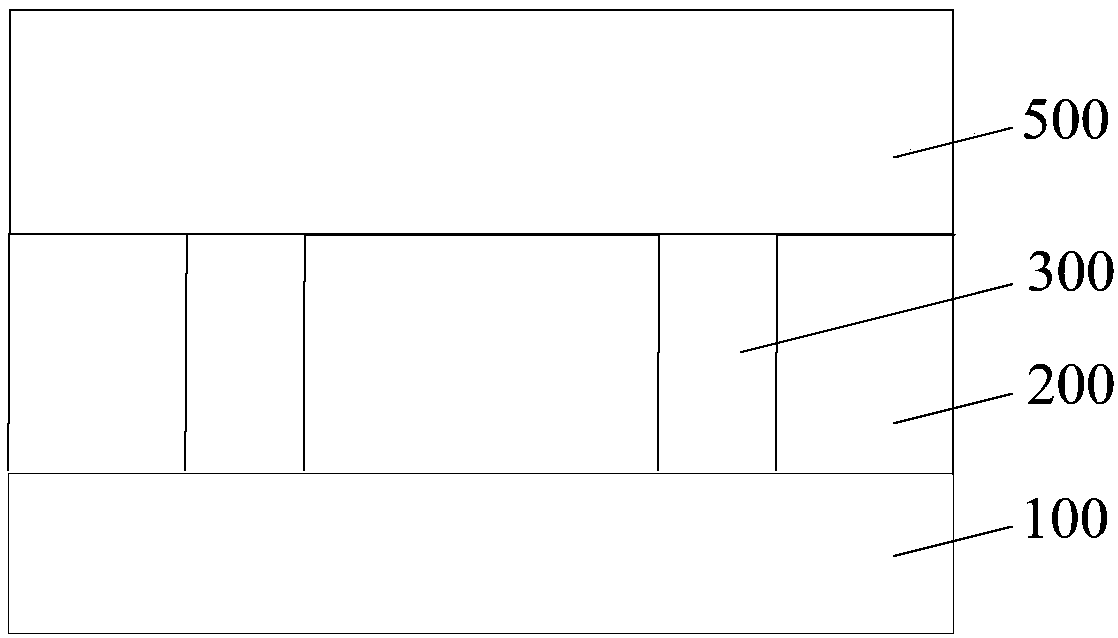

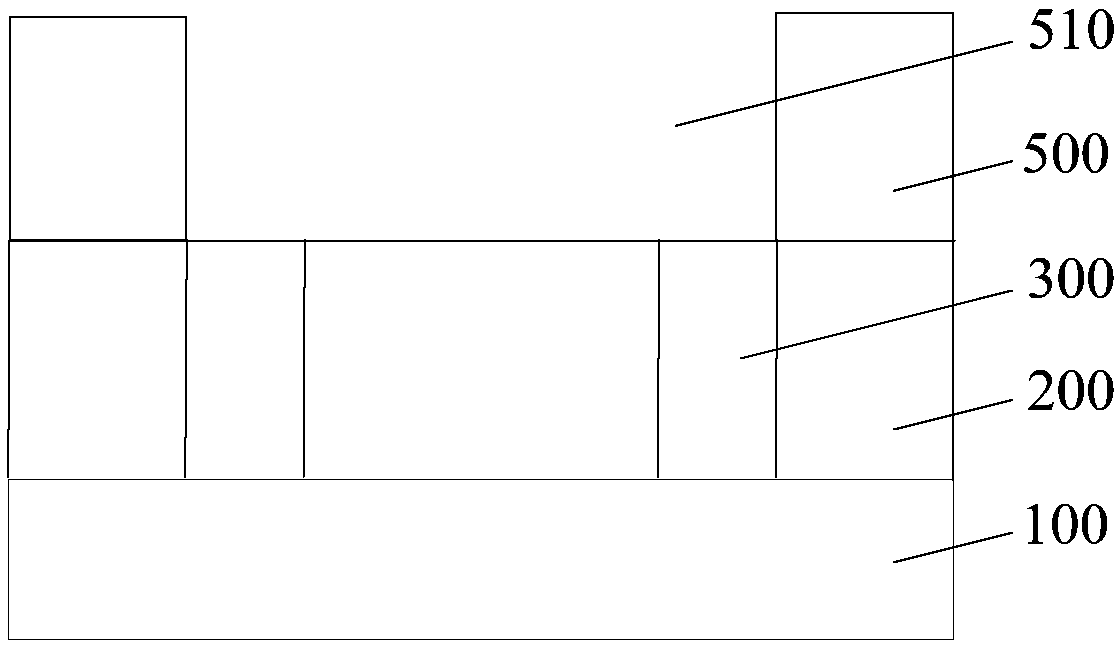

[0043] In order to solve the above problems, the present invention provides a phase change memory and a preparation method thereof, the preparation method comprising: providing a substrate, the substrate has a dielectric layer, and the dielectric layer has a groove running through the thickness of the dielectric layer; A conductive layer is filled in the trench, and the top of the conductive layer is lower than the top of the dielectric layer; a heating electrode layer is formed on the top of the conductive layer and the exposed groove sidewall of the conductive layer.

[0044] Wherein, a conductive layer is filled in the groove, and the top of the conductive layer is lower than the top of the first dielectric layer, so that the exposed side walls of the conductive layer and the top of the conductive layer are formed to form a heating layer. The electrode layer provides a space, so that the bottom of the formed heating electrode layer coincides with the top of the conductive laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com