Releasing device for clothing treating agent, washing machine and control method of releasing device

A technology for a clothing treatment agent and a dispensing device, which is applied to the control device of a washing machine, other washing machines, washing devices, etc., can solve various problems such as poor dispensing, inaccurate detergent, and complex structure, so as to achieve low production costs and improve Laundry effect, the effect of optimizing the structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

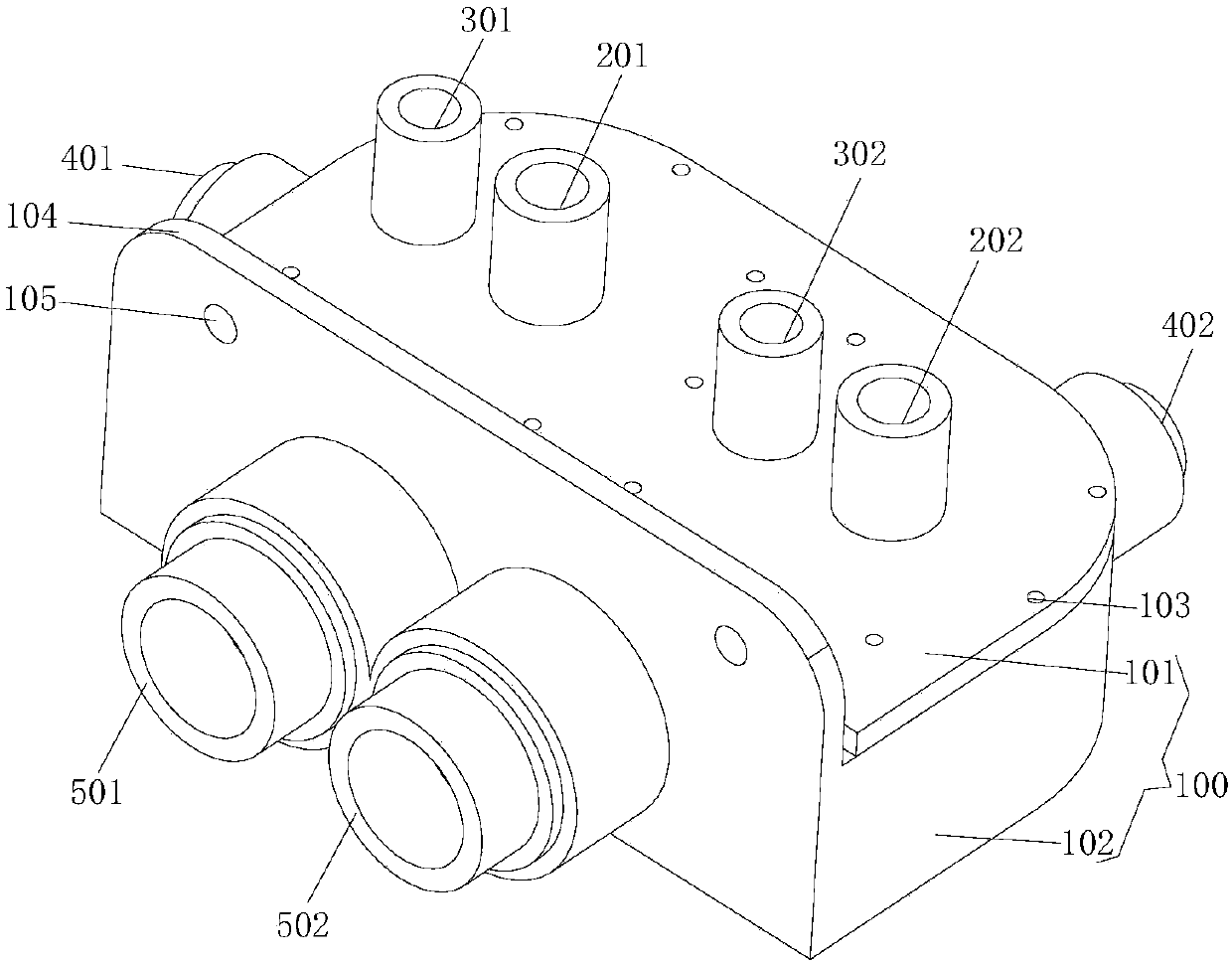

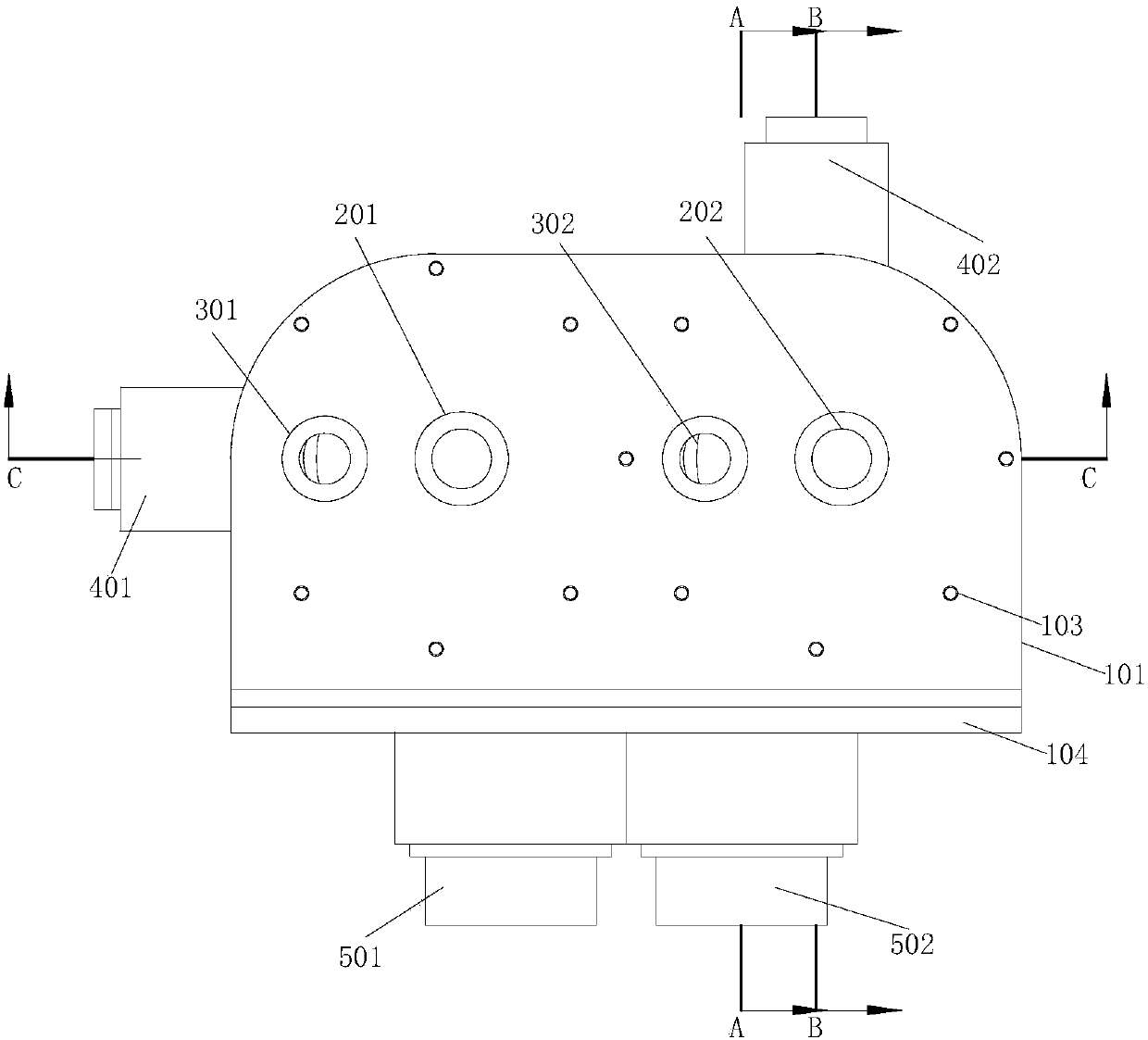

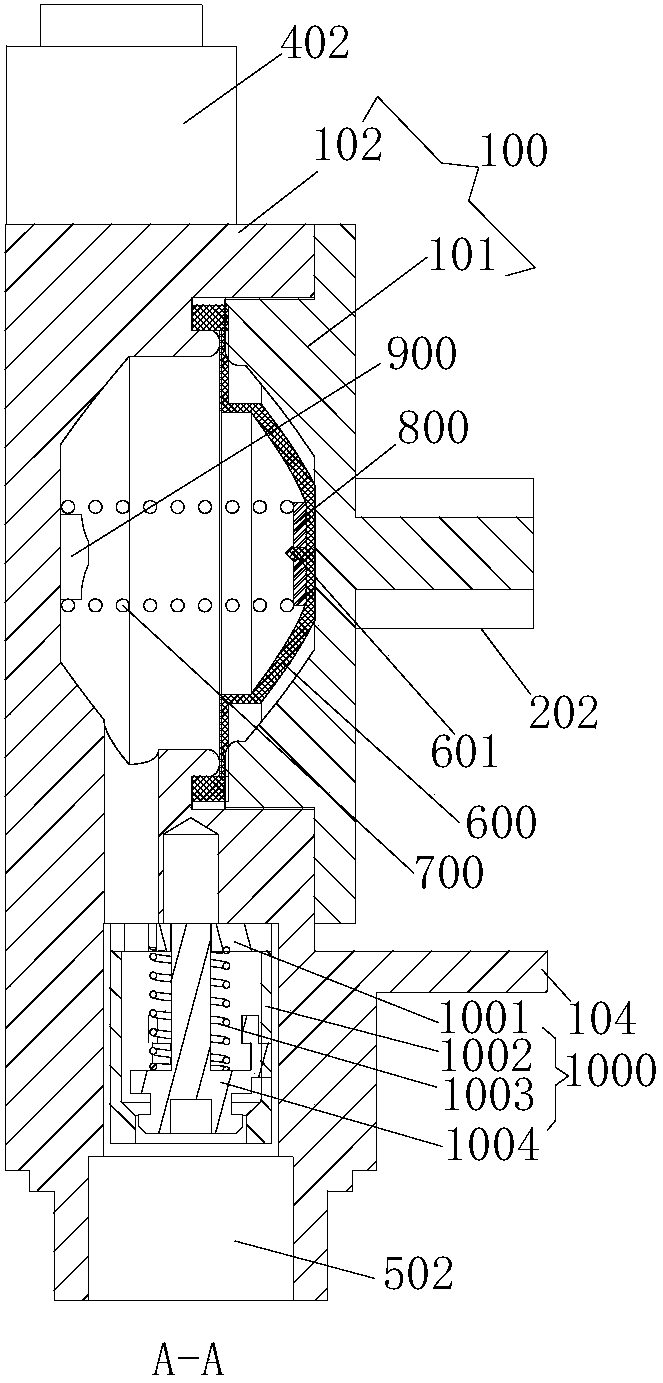

[0048] like Figure 1-Figure 5 As shown, the laundry treatment agent dispensing device of this embodiment includes a housing 100, and the housing 100 has at least two hollow chambers inside, and a flexible separator 600 is sealed and installed in each hollow chamber to separate each hollow chamber. It is a water inlet chamber and a liquid storage chamber; the housing 100 is respectively provided with a water inlet end and a pressure relief end connected with the water inlet chamber corresponding to each hollow chamber, and the water inlet end is connected with the water inlet pipeline of the washing machine; The housing 100 is provided with liquid outlets connected to the liquid storage chambers corresponding to the hollow chambers, and the liquid storage chambers are filled with laundry treatment agents; the water inlet of the washing machine enters the water inlet chamber from the water inlet end, and squeezes the flexible separator. The 600 is deformed toward the liquid sto...

Embodiment 2

[0070]The dispensing device of this embodiment further provides a one-way conduction device suitable for the liquid outlet and the liquid inlet on the basis of the first embodiment, specifically:

[0071] like Figure 3-Figure 5 As shown, the one-way conducting device 1000 described in this embodiment includes a valve body 1002, a valve cover 1001, a valve core 1004 and a return spring 1003. The valve body 1002 has a hollow passage inside; the valve cover 1001 is arranged on the valve body One end of the hollow channel of 1002, a valve hole is opened on the bonnet 1001; the valve core 1004 is arranged in the hollow channel of the valve body 1002, and one end of the spool 1004 can be relatively movable and installed on the bonnet 1001, and the other end is connected with the hollow channel. The channel openings of the channel are matched; one end of the return spring 1003 stops against the valve cover 1001, and the other end stops against the valve core 1004;

[0072] Specific...

Embodiment 3

[0078] This embodiment provides a washing machine with a laundry treatment agent dispensing device as described in Embodiment 1 or Embodiment 2, including a water inlet valve and a water collection box. The water inlet valve includes a first water outlet control port connected to the water collection box and a communication The second water outlet control end of each water inlet end of the delivery device, each pressure relief end and each liquid outlet end of the delivery device are respectively connected to the water collection box;

[0079] Preferably, the washing machine further includes a storage box for storing the laundry treatment agent, and each liquid inlet end of the injecting device is connected to the storage box.

[0080] In the control method of the washing machine in this embodiment, when it is necessary to inject a certain laundry treatment agent, the washing machine controls the laundry water to enter the water inlet corresponding to the laundry treatment agen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com