Device for continuously producing acidified oil and co-producing sodium sulfate crystal from nigre

A technology of sodium sulfate and acidified oil, applied in the field of soapstock processing, can solve the problems of large amount of waste water, inability to operate continuously, low soapstock conversion rate, etc., and achieve the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

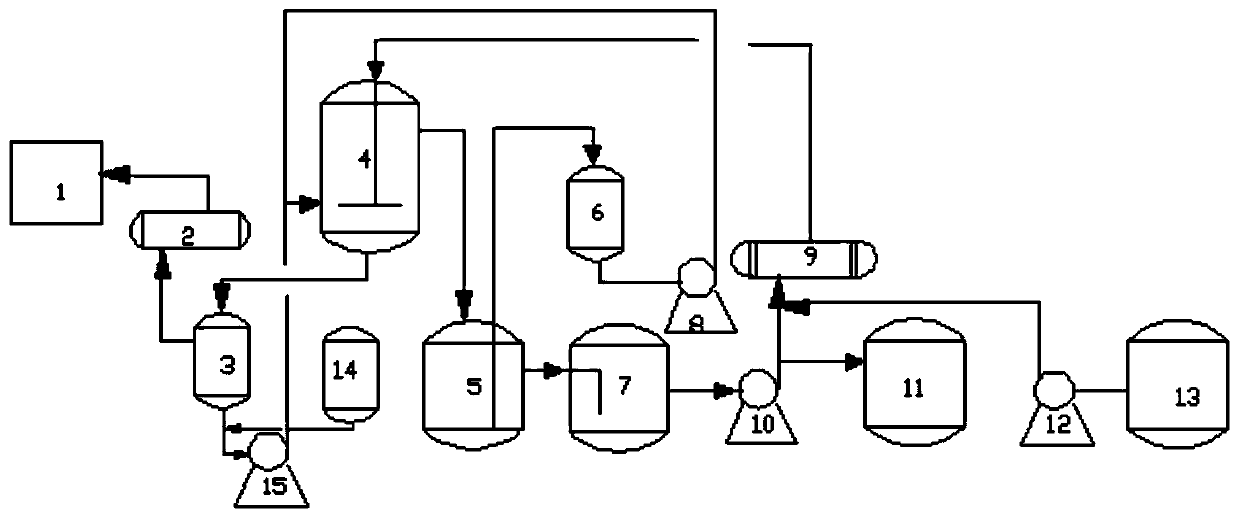

[0045] A device for the continuous production of acidified oil and by-product sodium sulfate crystals from soapstock, such as figure 1 As shown, it includes a vacuum system 1, a negative pressure storage tank 2, a suction filter tank 3, a reactor 4, a settling tank 5, a buffer tank 6, a circulating oil tank 7, an acid circulation pump 8, a heater 9, and a circulation Oil pump 10, acidizing oil tank 11, raw material pump 12, raw material tank 13, acid distribution tank 14, acid discharge pump 15; reactor 4 is a raw material reactor, and is provided with an acid liquid inlet, a soapstock inlet, an upper outlet Feed port and lower discharge port; Raw material tank 13 is used for storing reaction raw material soapstock, and raw material tank 13 is connected to heater 9 through raw material pump 12, and heater 9 is connected with the soapstock inlet of reactor 4, to the raw material The soapstock is sent to the bottom of the reactor 4 after heating; the upper discharge port and the...

Embodiment 2

[0047] A kind of technique of continuously producing acidified oil and by-product sodium sulfate crystal by soapstock, it utilizes the device of embodiment 1, and technological process is as follows:

[0048] a) Aqueous sulfuric acid is added in the reactor 4; the soapstock in the raw material tank 13 enters the heater 9 through the raw material pump 12, and enters the bottom of the reactor 4 through the soapstock feeding port after being heated by the heater 9; During the process of floating from the bottom to the upper layer, it fully contacts and reacts with the acid liquid, and the acidified oil and part of the acid liquid in the upper layer of the reactor 4 enter the settling tank 5 through the upper outlet of the reactor 4 for sedimentation;

[0049] b) The acidified oil in the upper layer of the settling tank 5 reaches the overflow port and then overflows to the acidified oil tank 11 or enters the acidized oil tank 11 through the oil phase circulation unit, and the other...

Embodiment 3

[0056]A kind of technique of continuously producing acidified oil and by-product sodium sulfate crystal by soybean soapstock raw material, it utilizes the device of embodiment 1, and concrete process flow step is as follows: add 35% sulfuric acid aqueous solution in the reactor 4, the soybean in the raw material tank 13 The soapstock raw material, after being heated to 50° C., passes through the raw material pump, and enters the reactor 4 after being heated to 70° C. by the heater 9 at a processing rate of 2 tons per hour. The acidification reaction takes place in reactor 4 . The upper oil layer enters the settling tank 5 through the outlet at the upper end of the reactor. The fatty acid in the upper layer of the settling tank 5 overflows to the circulating oil tank 7, and the part of the acidified oil in the circulating oil tank 7 forms a mixed oil product with the raw material through the heater 9 and returns to the reactor 4 to establish oil circulation, and the mixed solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com