MOF-based derivative composite photocatalyst and preparation method thereof

A technology of photocatalyst and nano-photocatalyst, which is applied in the direction of chemical instruments and methods, physical/chemical process catalysts, hydrogen production, etc., can solve complex and flexible coordination problems, improve conductivity, improve photocatalytic efficiency, and improve Effects of light absorption efficiency and photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

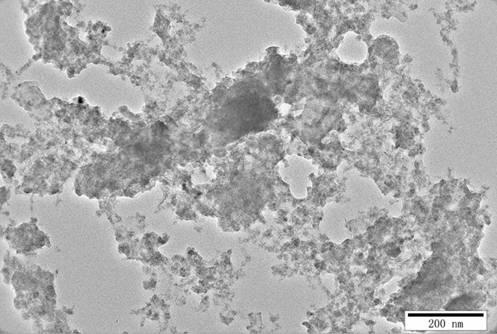

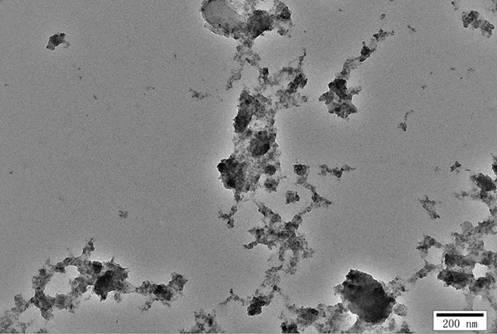

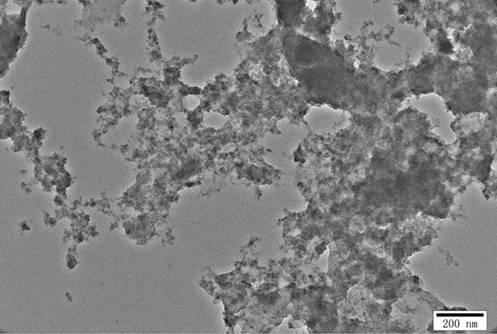

Image

Examples

Embodiment 1

[0021] 1) g-C 3 N 4 Preparation of / MXene / CuZnIn-MOF solid powder:

[0022] According to anhydrous zinc nitrate, anhydrous copper nitrate, anhydrous indium nitrate, 2-methylimidazole, terephthalic acid, g-C 3 N 4, The mass ratio of MXene and dimethylformamide is 5:20:5:15:4.5:5:0.5:45, anhydrous zinc nitrate, anhydrous copper nitrate, anhydrous indium nitrate, 2-methyl Imidazole, terephthalic acid, g-C 3 N 4 , MXene and dimethylformamide were mixed, and the above mixed solution was solvothermally reacted at 120 ° C for 38 hours. g-C was obtained after drying at ℃ 3 N 4 / MXene / CuZnIn-MOF solid powder.

[0023] 2) g-C 3 N 4 / MXene / CuZnIn 2 S 4 Preparation of composite photocatalyst:

[0024] According to g-C 3 N 4 The mass ratio of / MXene / CuZnIn-MOF solid powder, thiourea and deionized water is 40:10:50, the g-C 3 N 4 / MXene / CuZnIn-MOF solid powder, thiourea and deionized water were mixed, and the above mixed solution was solvothermally reacted at 140°C for 35 h...

Embodiment 2

[0027] 1) g-C 3 N 4 / MXene / CuZnIn-MOF solid powder preparation:

[0028] According to anhydrous sulfur zinc, anhydrous sulfur copper, anhydrous sulfur indium, 2-methylimidazole, terephthalic acid, g-C 3 N 4 The mass ratio of , MXene and dimethylformamide is 16:5:14:17:13:4.8:0.2:30, according to the ratio of anhydrous sulfur zinc, anhydrous sulfur copper, anhydrous sulfur indium, 2-methyl imidazole, terephthalic acid, g-C 3 N 4 , MXene and dimethylformamide were mixed, and the above mixed solution was solvothermally reacted at 200 ° C for 24 hours. After the reaction was completed, after natural cooling, centrifugal separation was carried out, and then fully washed with deionized water and absolute ethanol in sequence. g-C was obtained after drying at ℃ 3 N 4 / MXene / CuZnIn-MOF solid powder.

[0029] 2) g-C 3 N 4 / MXene / CuZnIn 2 S 4 Preparation of composite photocatalyst:

[0030] According to g-C 3 N 4 The mass ratio of / MXene / CuZnIn-MOF solid powder, thioacetam...

Embodiment 3

[0033] 1) g-C 3 N 4 Preparation of / MXene / CuZnIn-MOF solid powder:

[0034] According to anhydrous zinc chloride, anhydrous copper chloride, anhydrous indium chloride, 2-methylimidazole, terephthalic acid, g-C 3 N 4 The mass ratio of , MXene and dimethylformamide is 5:18:12:10:5:9:1:40, anhydrous zinc chloride, anhydrous copper chloride, anhydrous indium chloride, 2 -Methylimidazole, terephthalic acid, g-C 3 N 4 , MXene and dimethylformamide were mixed, and the above mixed solution was solvothermally reacted at 280 ° C for 6 hours. After the reaction was completed, after natural cooling, centrifugal separation was carried out, and then fully washed with deionized water and absolute ethanol in turn, at 80 g-C was obtained after drying at ℃ 3 N 4 / MXene / CuZnIn-MOF solid powder.

[0035] 2) g-C 3 N 4 / MXene / CuZnIn 2 S 4 Preparation of composite photocatalyst:

[0036] According to g-C 3 N 4 The mass ratio of / MXene / CuZnIn-MOF solid powder, thioacetamide and deioniz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com