Method for improving adsorption performance of noodles and noodles

A technology for adsorption performance and noodles, which is applied to methods and noodles to improve adsorption performance of noodles. Chewy, increase the effect of surface unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

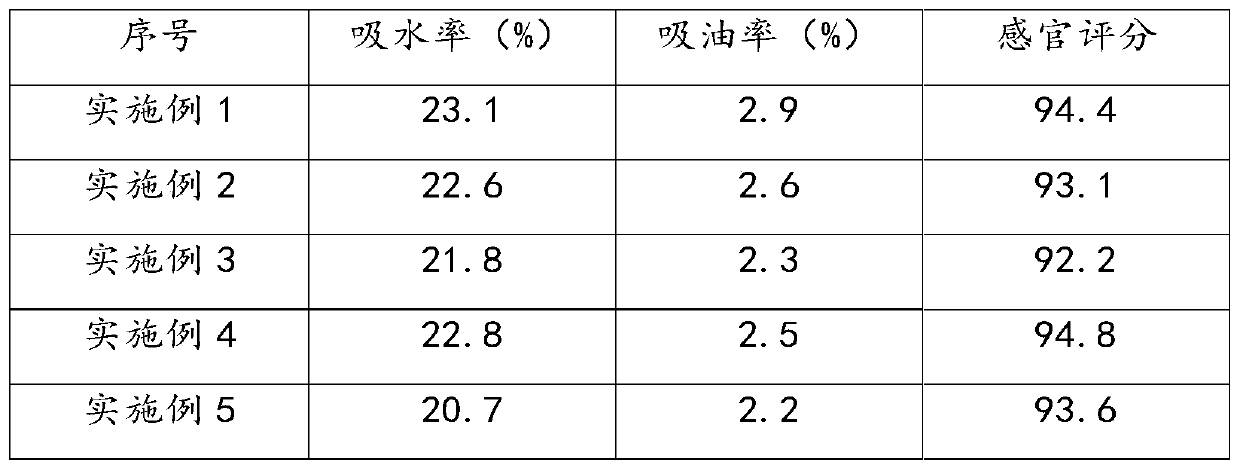

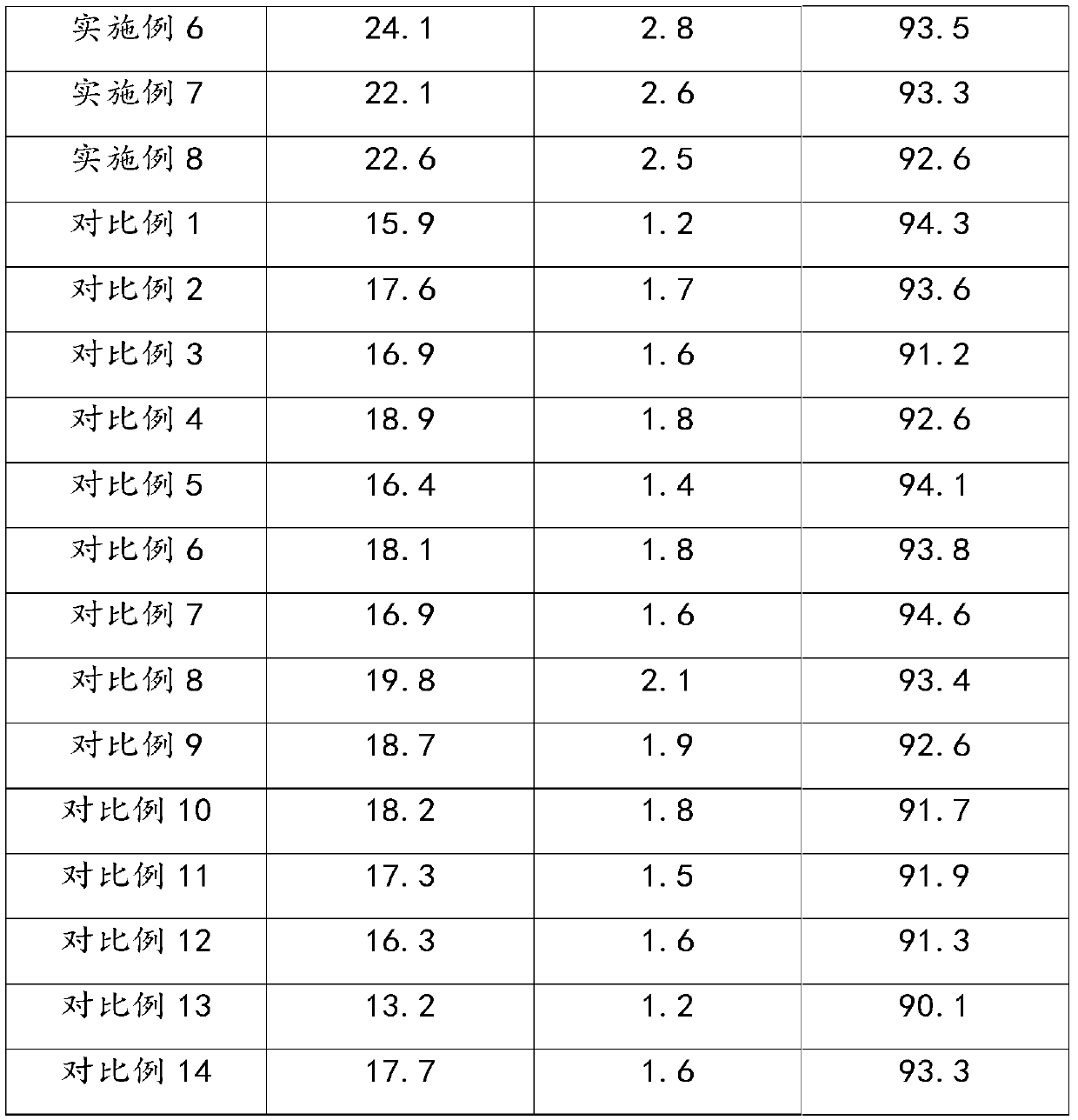

Examples

Embodiment 1

[0100] A method for improving the adsorption performance of noodles, comprising the steps of:

[0101] (a) Add sodium carbonate accounting for 5% of the dry starch mass to the dry starch, then slowly add water until the mass concentration of the starch liquid is 30%, stir and mix evenly; then add the starch liquid to the obtained starch liquid 10% acetic anhydride by mass, stirred evenly, adjusted the pH value of the reaction system to 8, and reacted for 3 hours at a reaction temperature of 25°C; then filtered at room temperature, and washed with an aqueous ethanol solution with a mass concentration of 70% for 3 times, then washed 4 times with distilled water, and dried at a temperature of 50°C;

[0102] Mix the starch obtained by acetylation with water to form a starch slurry, adjust the pH of the starch slurry, and preheat it in a water bath; add α-amylase with a mass ratio of 1:5 to the starch slurry according to 5% of the dry weight of the starch and a compound enzyme com...

Embodiment 2

[0107] A method for improving the adsorption performance of noodles, the difference from Example 1 is:

[0108] (a) Add 3% sodium carbonate accounting for the dry starch mass to the dry starch, then slowly add water until the mass concentration of the starch solution is 25%, stir and mix evenly; then add the starch solution to the obtained starch solution 6% acetic anhydride by mass, stir evenly, adjust the pH value of the reaction system to 8.5, and react at a reaction temperature of 32°C for 2.5h; then filter at room temperature, and wash with an aqueous ethanol solution with a mass concentration of 70% after filtration 4 times, then washed 6 times with distilled water, and dried at a temperature of 45°C;

[0109] All the other are identical with embodiment 1.

Embodiment 3

[0111] A method for improving the adsorption performance of noodles, the difference from Example 1 is:

[0112] (a) Mix the starch obtained by acetylation with water to form a starch slurry, adjust the pH of the starch slurry, and preheat it in a water bath; add α with a mass ratio of 1:3 to the starch slurry according to 4% of the dry weight of the starch -Composite enzyme composed of amylase and glucoamylase, and the temperature is 40°C with continuous stirring to make it fully react, the reaction time is 3.5h; after the reaction is completed, carry out post-treatment to obtain pre-treated starch;

[0113] All the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com