A steel-uhpc thin plate composite structure system for rapid assembly of steel plate brackets and clustered inclined nails

A combined structure and steel plate technology, applied in bridge materials, buildings, bridge construction, etc., can solve the problems of complex construction process and inconvenient implementation, and achieve the effects of improving integrity, crack resistance, and shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

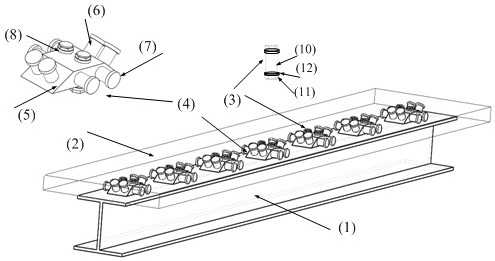

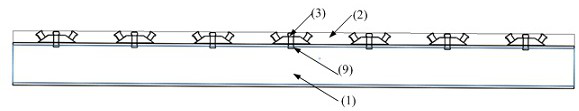

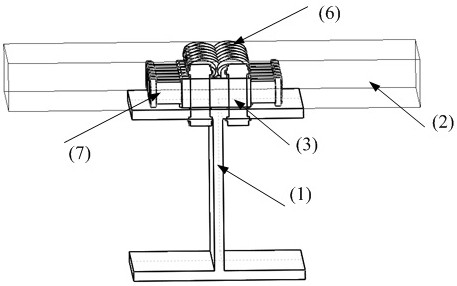

[0029] The invention is a high-performance steel-UHPC thin plate composite structure system and an interface connection technology adapted thereto. The structural system mainly includes UHPC thin plates 2 laid on steel beams 1 and combined shear members 4 connected by high-strength friction bolts 3, where combined shear members 4 are composed of steel plate supports 5 and large-diameter oblique short nails 6 And the short nails 7 on the front and back end faces are combined.

[0030] The short nails are large pegs with a diameter of 30mm.

[0031] The length of the hypotenuse of the steel plate meets the diameter of the short nail and welding requirements, and the thickness of the steel plate support is determined according to the length of the hypotenuse and the inclination angle.

[0032] The bridge deck is made of UHPC sheet with mixed fiber configuration, the thickness of which is about 50mm, and the mixed fiber is made of straight steel fiber with a volume content of 1% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com