Magnetic field heat treatment method for improving high frequency magnetic property of iron based nanocrystal

A technology of iron-based nanocrystals and heat treatment methods, applied in heat treatment furnaces, heat treatment equipment, inductors/transformers/magnets manufacturing, etc., can solve problems such as inductance drop, unstable magnetic performance, and increased core energy loss, etc., to achieve reduction Loss, the effect of increasing the effective permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

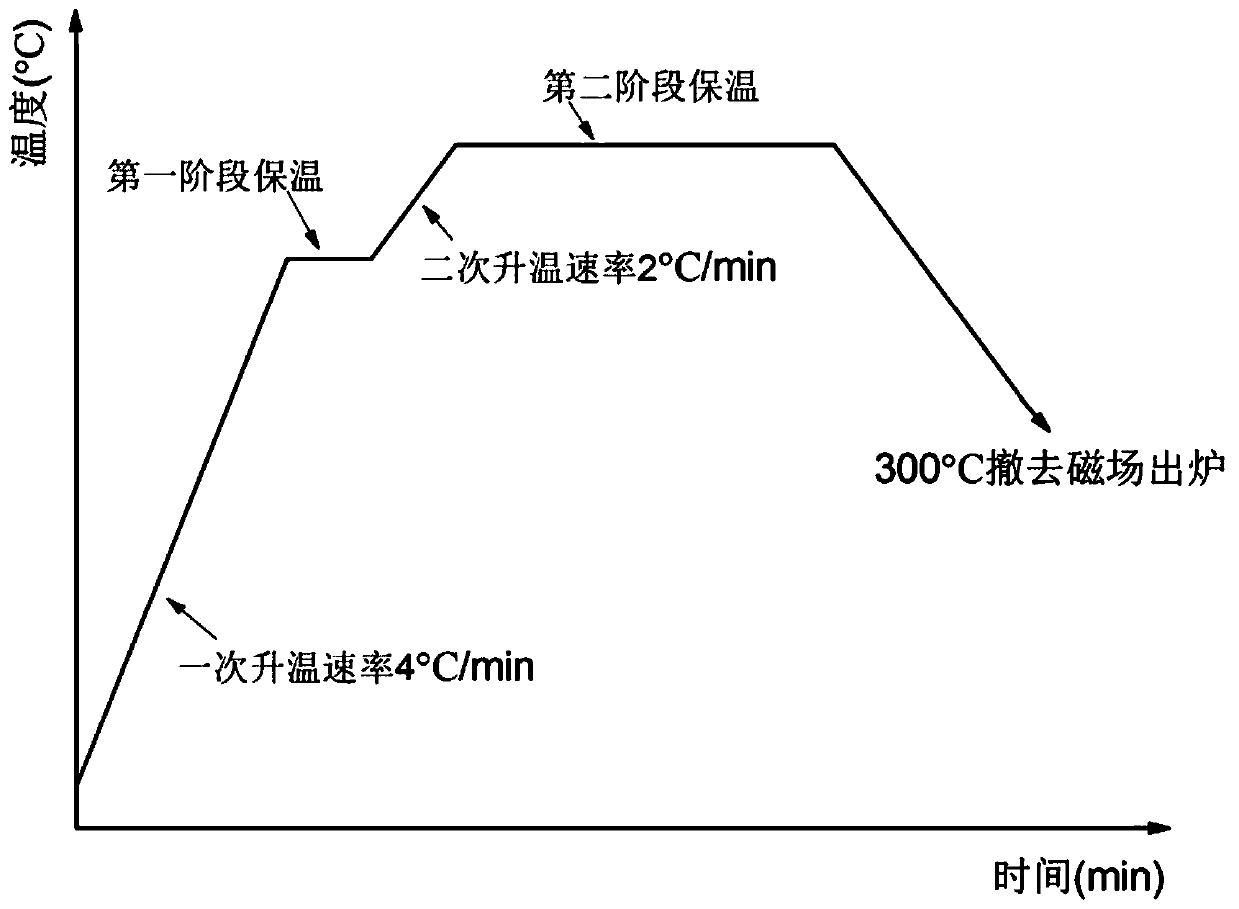

[0033] Such as Figure 1 to Figure 6 As shown, this embodiment discloses a magnetic field heat treatment method for improving the high-frequency magnetic properties of iron-based nanocrystals. The magnetic field heat treatment method mainly includes the following steps:

[0034] Step S1: Roll the strip into a ring core with outer diameter, inner diameter, and height of 23*15*10mm respectively. In order to ensure that the core has the same lamination coefficient K, the ring core can be processed under different process conditions. The performance test is comparative, and this step is realized by controlling the linear speed of strip rolling, the magnitude of stress and the weight of the magnetic core.

[0035] Step S2: The heat treatment of the annular magnetic core is carried out in two system devices respectively. First, the magnetic core is placed in a heat treatment tube furnace for crystallization annealing treatment, and the ɑ-Fe(Si) nanocrystalline phase is precipitated....

Embodiment 2

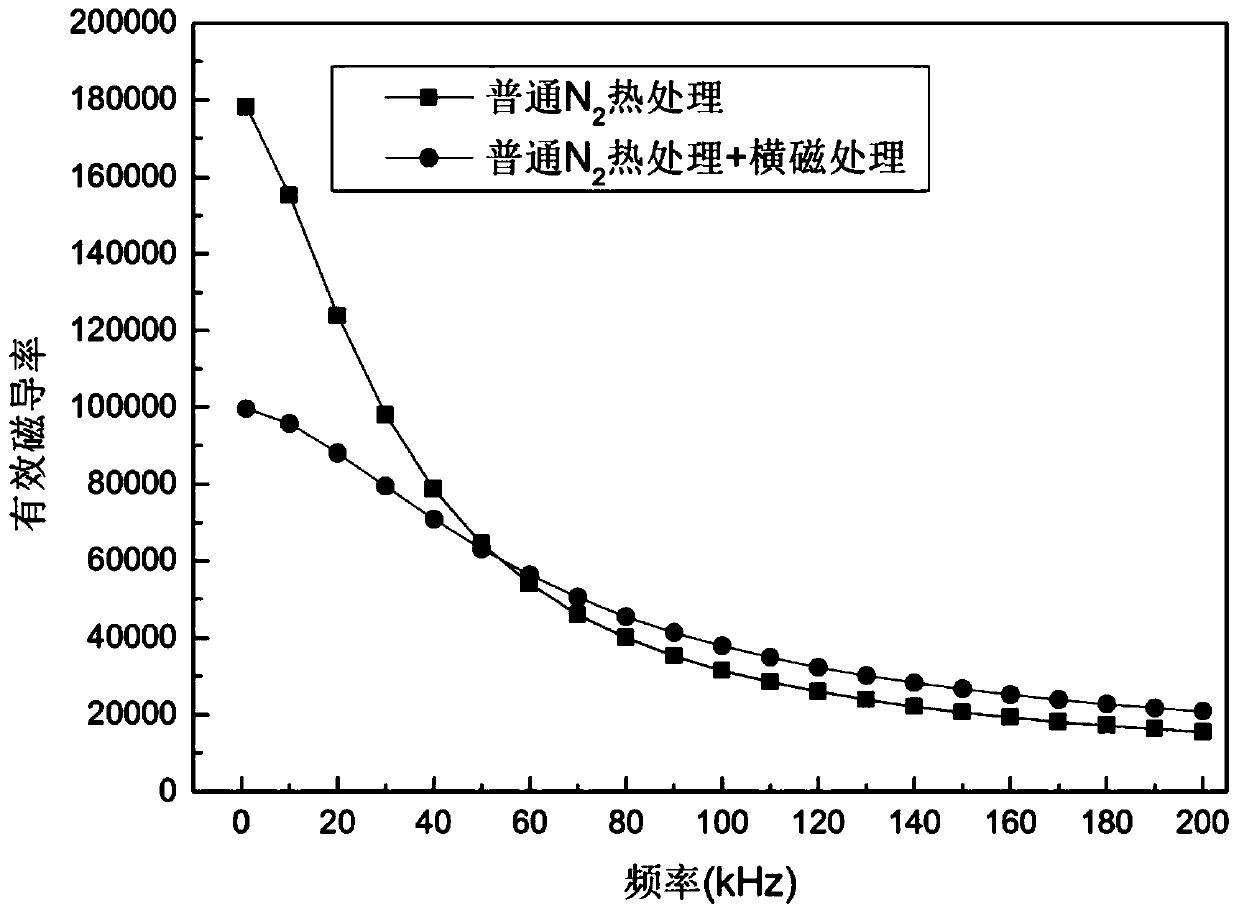

[0047] This embodiment discloses a magnetic field heat treatment method for iron-based nanocrystals. Through research, it is found that improving the high-frequency soft magnetic properties of amorphous nanocrystal magnetic materials can be done from the perspectives of material composition, strip thickness, and heat treatment process. Bring to purpose. The required amorphous and nanocrystalline strips of the present invention are provided by Dongguan Meiyi Magnetic Technology Co., Ltd., and the nominal composition of the strips is Fe 73.5 Si 15.5 B 7 Cu 1 Nb 3 , the strip width is 10mm, and the thickness is 18±2um.

[0048] The technical solution is as follows:

[0049] 1) Roll the strip into an annular magnetic core with outer diameter*inner diameter*height = 23*15*10mm, in order to ensure that the magnetic core has the same lamination coefficient K, so that the performance of the annular magnetic core after processing under different process conditions The test is com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com