Surface paint waxing coating technology for outdoor tables and chairs

A table, chair, and outdoor technology, which is applied to the device, coating, and coating dipping on the surface. , The effect of low production cost, convenient and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

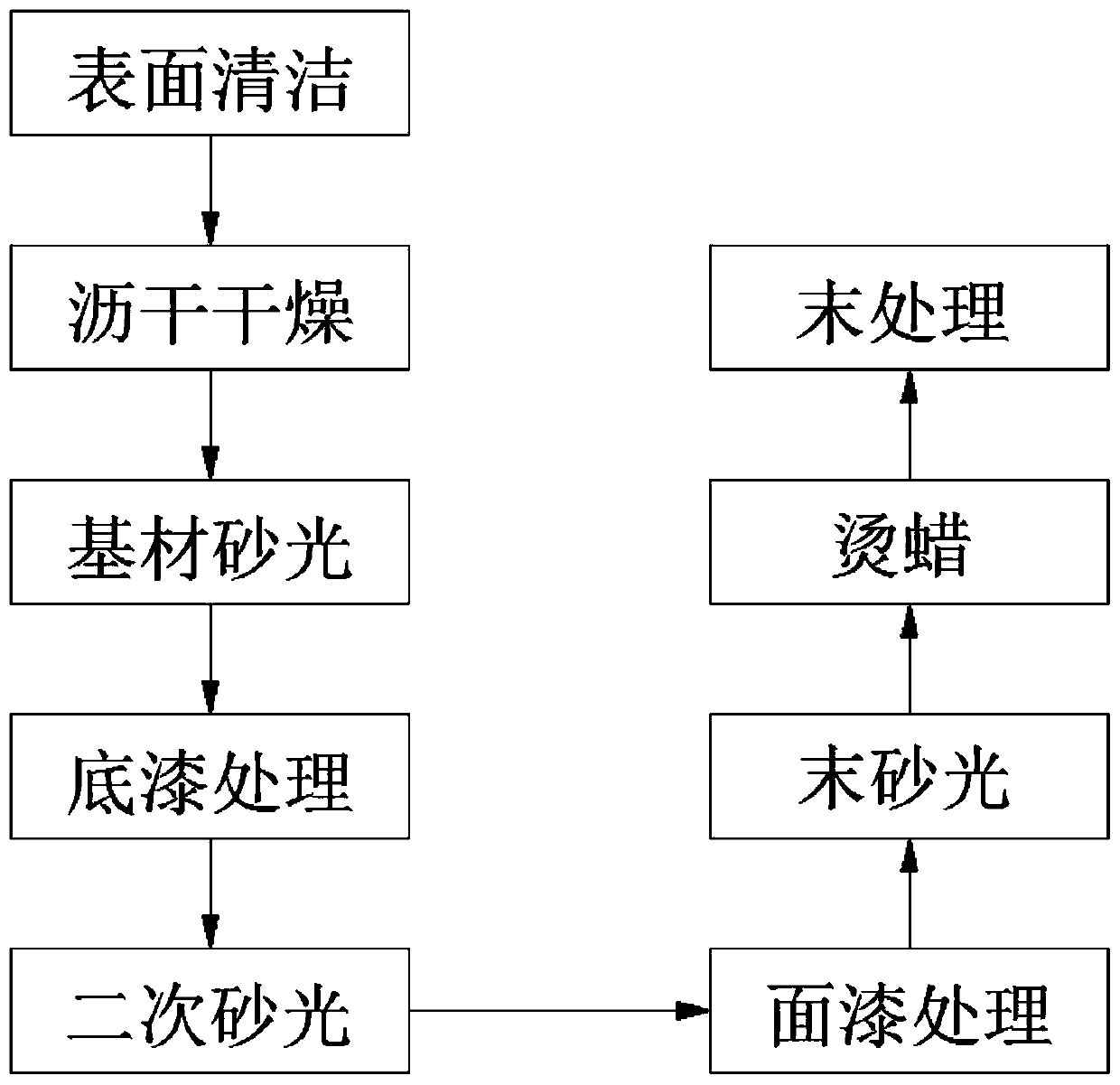

[0034] A kind of method that the present invention proposes is used for the surface varnish wax finishing of outdoor tables and chairs, comprises the following steps:

[0035] S1 surface cleaning: Spray and wash the outdoor tables and chairs with deionized water twice, and spray and wash once every 5 minutes to clean the surface of the outdoor tables and chairs;

[0036] S2 Drain and dry: Take out the outdoor tables and chairs and place them in a place where the light intensity is 1.0*10 5 Under the environment of 1x, drain for 40 minutes, and dry until the surface moisture content is 5%;

[0037] S3 base material sanding: Use 1200#, 1000#, 800# sandpaper to sand the outdoor tables and chairs along the wood grain in sequence;

[0038] S4 primer treatment: manually spray the primer on the surface of outdoor tables and chairs, and ensure that the final spraying amount on one side is 15g / m 2 ;

[0039] S5 secondary sanding: Use 600#, 500#, 400# sandpaper to sand the outdoor ta...

Embodiment 2

[0046] A kind of method that the present invention proposes is used for the surface varnish wax finishing of outdoor tables and chairs, comprises the following steps:

[0047] S1 surface cleaning: Spray and wash the outdoor tables and chairs with deionized water twice, and spray and wash once every 6 minutes to clean the surface of the outdoor tables and chairs;

[0048] S2 Drain and dry: Take out the outdoor tables and chairs and place them in a place with a light intensity of 1.1*10 5 Under the environment of 1x, drain for 45 minutes, and dry until the surface moisture content is 6%;

[0049] S3 base material sanding: Use 1200#, 1000#, 800# sandpaper to sand the outdoor tables and chairs along the wood grain in sequence;

[0050] S4 primer treatment: manually spray the primer on the surface of outdoor tables and chairs, and ensure that the final spraying amount on one side is 17g / m 2 ;

[0051] S5 secondary sanding: Use 600#, 500#, 400# sandpaper to sand the outdoor table...

Embodiment 3

[0058] A kind of method that the present invention proposes is used for the surface varnish wax finishing of outdoor tables and chairs, comprises the following steps:

[0059] S1 surface cleaning: Spray and wash the outdoor tables and chairs with deionized water twice, and spray and wash once every 8 minutes to clean the surface of the outdoor tables and chairs;

[0060] S2 Drain and dry: Take out the outdoor tables and chairs and place them in a place with a light intensity of 1.1*10 5 Under the environment of 1x, drain for 50 minutes, and dry until the surface moisture content is 8%;

[0061] S3 base material sanding: Use 1200#, 1000#, 800# sandpaper to sand the outdoor tables and chairs along the wood grain in sequence;

[0062] S4 primer treatment: manually spray the primer on the surface of outdoor tables and chairs, and ensure that the final spraying amount on one side is 18g / m 2 ;

[0063] S5 secondary sanding: Use 600#, 500#, 400# sandpaper to sand the outdoor table...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com