Hole reservation plugging device for construction engineering

A technology of construction engineering and plugging device, which is applied in construction, building structure, processing of building materials, etc., can solve the problems of separation of plugging tools from holes, inconvenient cement removal, etc., and achieve the effect of avoiding residual impurities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

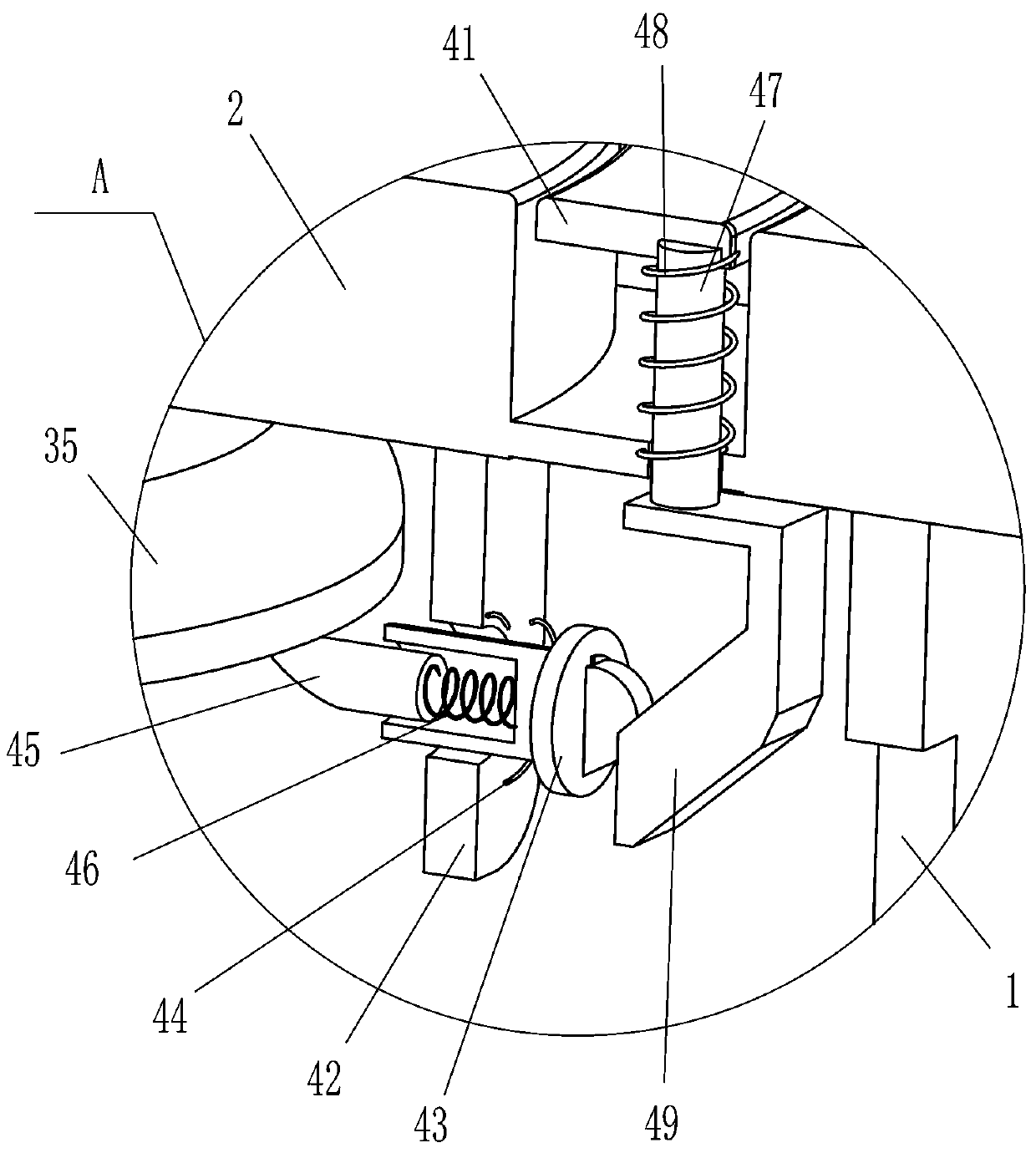

[0020] see figure 1 , figure 2 and Figure 4 , a hole reserved plugging device for construction engineering, including a shell 1, a grooved plate 2, a fixing mechanism 3 and a limit mechanism 4, the top of the shell 1 is fixedly connected with a grooved plate 2, and the grooved plate 2 is A limiting mechanism 4 is provided, and a fixing mechanism 3 is arranged on the housing 1 , and the fixing mechanism 3 cooperates with the limiting mechanism 4 .

[0021] Fixing mechanism 3 includes movable clamping lever 31, first spring 32, conical block 33, second spring 34 and first strong magnet 35, and the middle part of housing 1 front and back, left and right sides all slides and is provided with movable clamping lever 31, movable A first spring 32 is wound between the inside of the clamp rod 31 and the inner surface of the housing 1, and the middle part of the housing 1 is provided with a conical block 33. A second spring 34 is connected between the inner bottom of the housing 1 ...

Embodiment 2

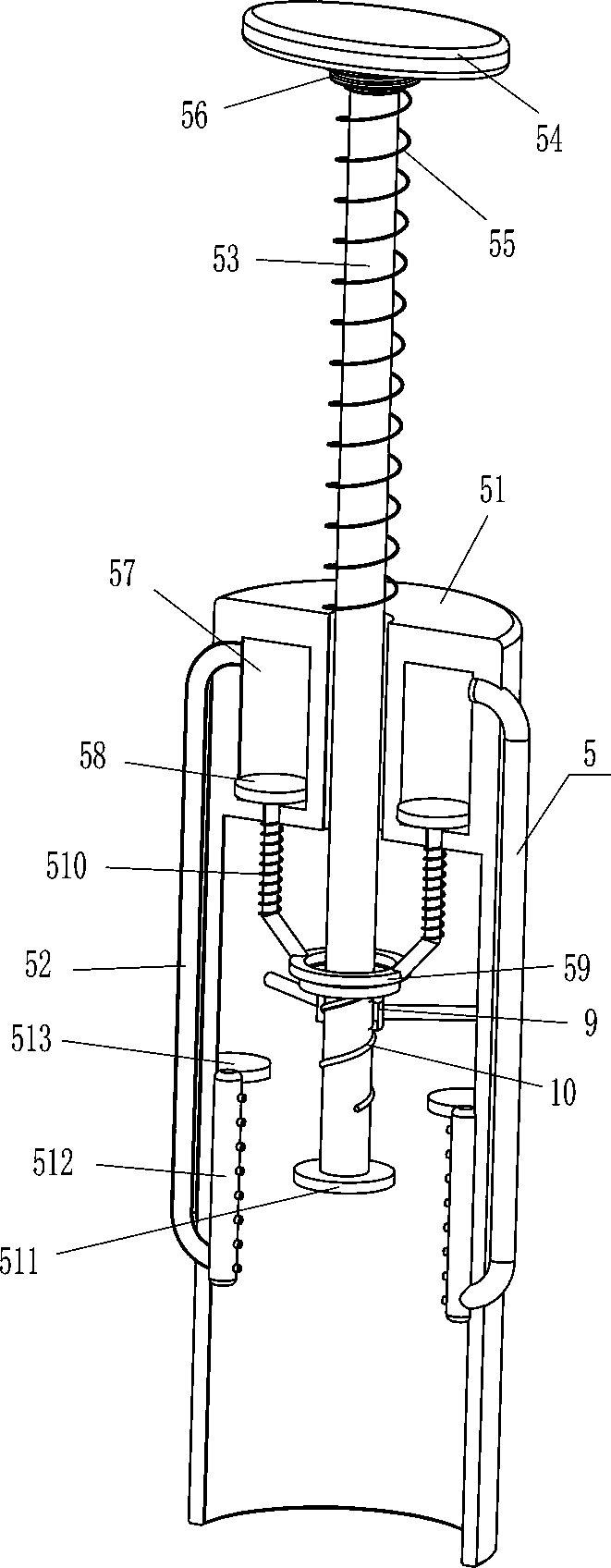

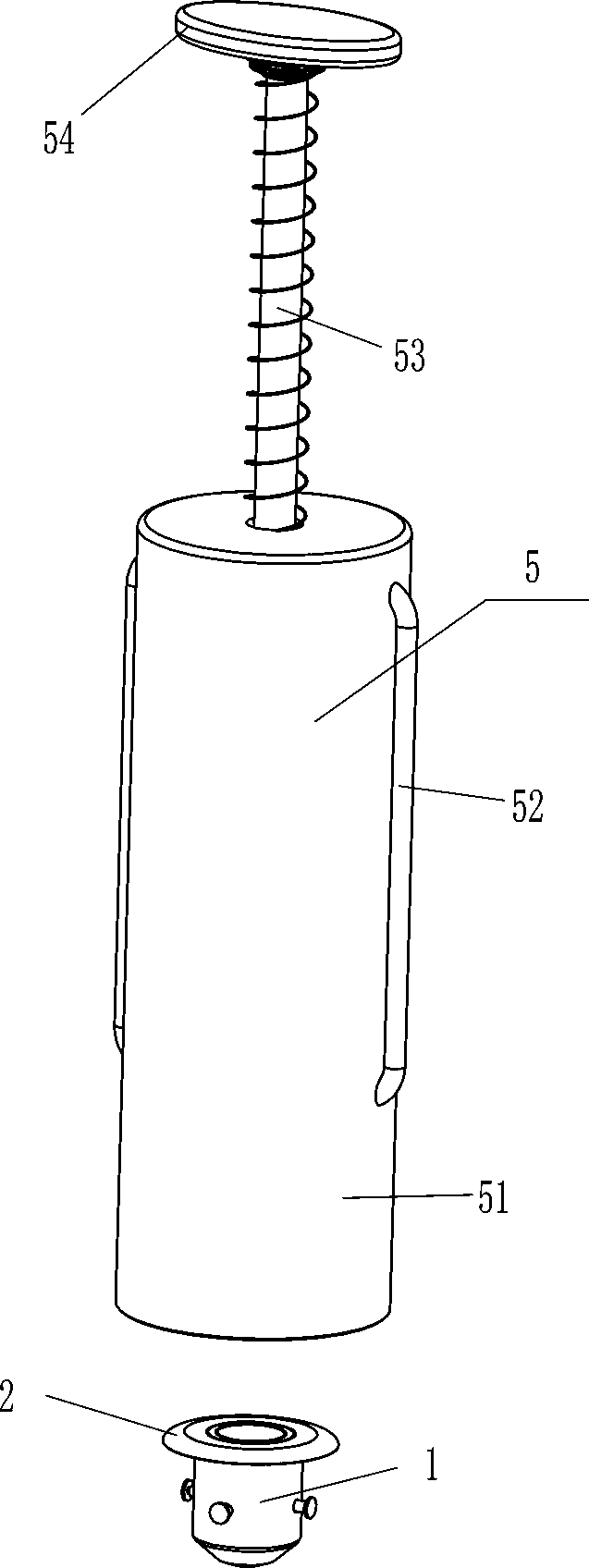

[0027] see figure 1 and image 3 Compared with Embodiment 1, the main difference of this embodiment is that in this embodiment, a clamping mechanism 5 is also included, and the clamping mechanism 5 includes a cylinder 51, a connecting pipe 52, a movable rod 53, a turning block 54, a sixth Spring 55, the first ring block 56, piston rod 58, the second ring block 59, the seventh spring 510, the second strong magnet 511, the jet pipe 512 and the fixed block 513, the middle sliding type of cylinder body 51 is provided with Movable rod 53, the top of movable rod 53 is connected with rotating block 54, the upper part of movable rod 53 is covered with first ring block 56, and the sixth spring is connected between the bottom of first ring block 56 and the outer top of cylinder body 51 55, the sixth spring 55 is sleeved on the movable rod 53, the bottom end of the movable rod 53 is fixedly connected with the second strong magnet 511, the lower part of the movable rod 53 is covered with...

Embodiment 3

[0030] see figure 2 and image 3 The main difference between this embodiment and embodiment 1 and embodiment 2 is that in this embodiment, a T-shaped bar 6 and an eighth spring 7 are also included. A T-shaped bar 6 is slidingly provided in the groove 8, and an eighth spring 7 is connected between the inner end of the T-shaped bar 6 and the inner surface of the chute 8 .

[0031] Also include nut 9, the movable rod 53 bottom has thread 10, the movable rod 53 bottom is provided with nut 9 through thread 10, and the outer surface of nut 9 is fixedly connected with cylinder body 51 inner surface top.

[0032] When the conical block 33 drives the movable clamping rod 31 to move outwards, the movable clamping rod 31 also drives the T-shaped rod 6 to move outwards, and the T-shaped rod 6 moves outwards to contact the inner wall of the hole. Due to the effect of the eighth spring 7, the T-shaped The rod 6 is always in contact with the inner wall of the hole. In this way, the movab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com