Evaporation concentration system

An evaporative concentration system, cooling water system technology, applied in the direction of evaporation, evaporator accessories, chemical instruments and methods, etc., can solve the problems of untimely discharge, damage to pipes and valves, insufficient utilization of condensed water, etc. Increase the cooling effect, prevent the effect of liquid shock and air entrapment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

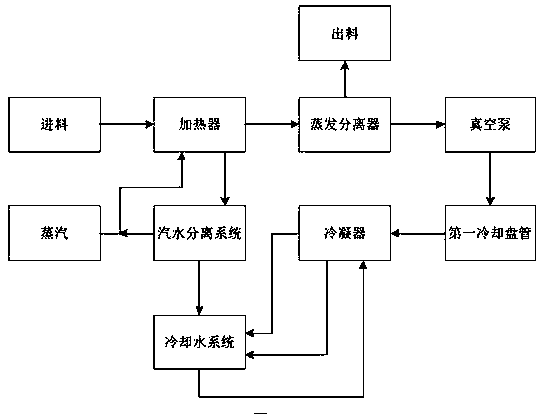

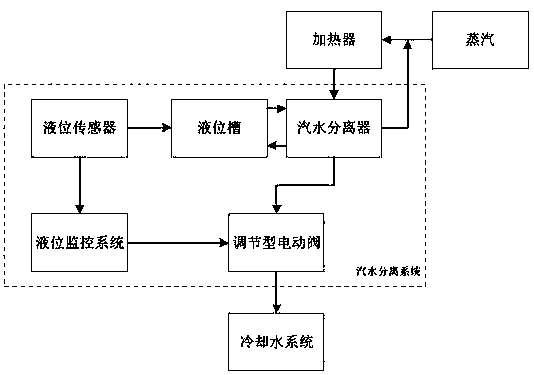

[0032] Refer to attached Figure 1-4 As shown, an evaporative concentration system includes a heater and an evaporative separator, the outlet of the heater is connected to the feed port of the evaporative separator, and a steam-water separation system is connected to the heater; the steam-water separation system Including steam-water separator, liquid level tank, liquid level sensor, liquid level monitoring system and regulating electric valve, steam-water separator is connected with liquid level tank, liquid level sensor is set inside liquid level tank, regulating electric valve and steam-water separator The drain port is connected, the liquid level monitoring system is connected with the liquid level sensor, and the liquid level monitoring system is connected with the regulating electric valve; the liquid level monitoring system controls the opening degree of the regulating electric valve according to the liquid level sensor.

[0033] When the evaporative concentration syste...

Embodiment 2

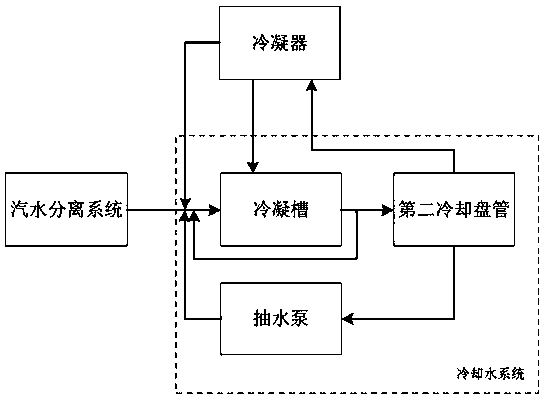

[0040] Please refer to Figure 1-4 As shown, the difference between this embodiment and Embodiment 1 is that this embodiment optimizes the design of the cooling water system and better recovers the water vapor generated by evaporation and separation.

[0041] In this embodiment, a first cooling curved plate is also included, and the first cooling curved plate is arranged between the vacuum pump and the condenser. The first cooling curved plate accelerates the cooling and liquefaction of water vapor to increase the liquefaction speed. If the vacuum book directly extracts water vapor into the air, water resources will be wasted, and the surrounding air humidity will be increased at the same time, and there will be a hidden danger of rusting of the equipment. Using a condenser to treat the water vapor generated by the evaporative separator may have insufficient liquefaction speed, which will lead to blockage of the pipe, resulting in an increase in the pressure in the pipe, and ...

Embodiment 3

[0045] Please refer to Figure 1-4 As shown, the difference between this embodiment and Embodiment 2 is that this embodiment optimizes the drainage structure of the steam-water separator to prevent special accidents.

[0046] In this embodiment, a first shut-off valve and a second shut-off valve are also included. The first shut-off valve is arranged between the drain port of the steam-water separator and the adjustable electric valve, and the second shut-off valve is arranged between the steam-water separator and the cooling water outlet. between systems. Two cut-off valves are set to prevent the regulating electric valve from malfunctioning. The first cut-off valve can be used to close the pipeline, and the second cut-off valve can be used to open the second pipeline to ensure drainage. When the first stop valve is in the open state, the second stop valve is in the closed state; when the first stop valve is in the closed state, the second stop valve is in the open state. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com