Flexible transparent conductive film and preparation method thereof

A transparent conductive film, flexible technology, applied in cable/conductor manufacturing, conductive layer on insulating carrier, circuit, etc., can solve the problems of graphene damage, low preparation efficiency, uneven conduction of the film, etc., and achieve good conduction uniformity , the preparation equipment and method are simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

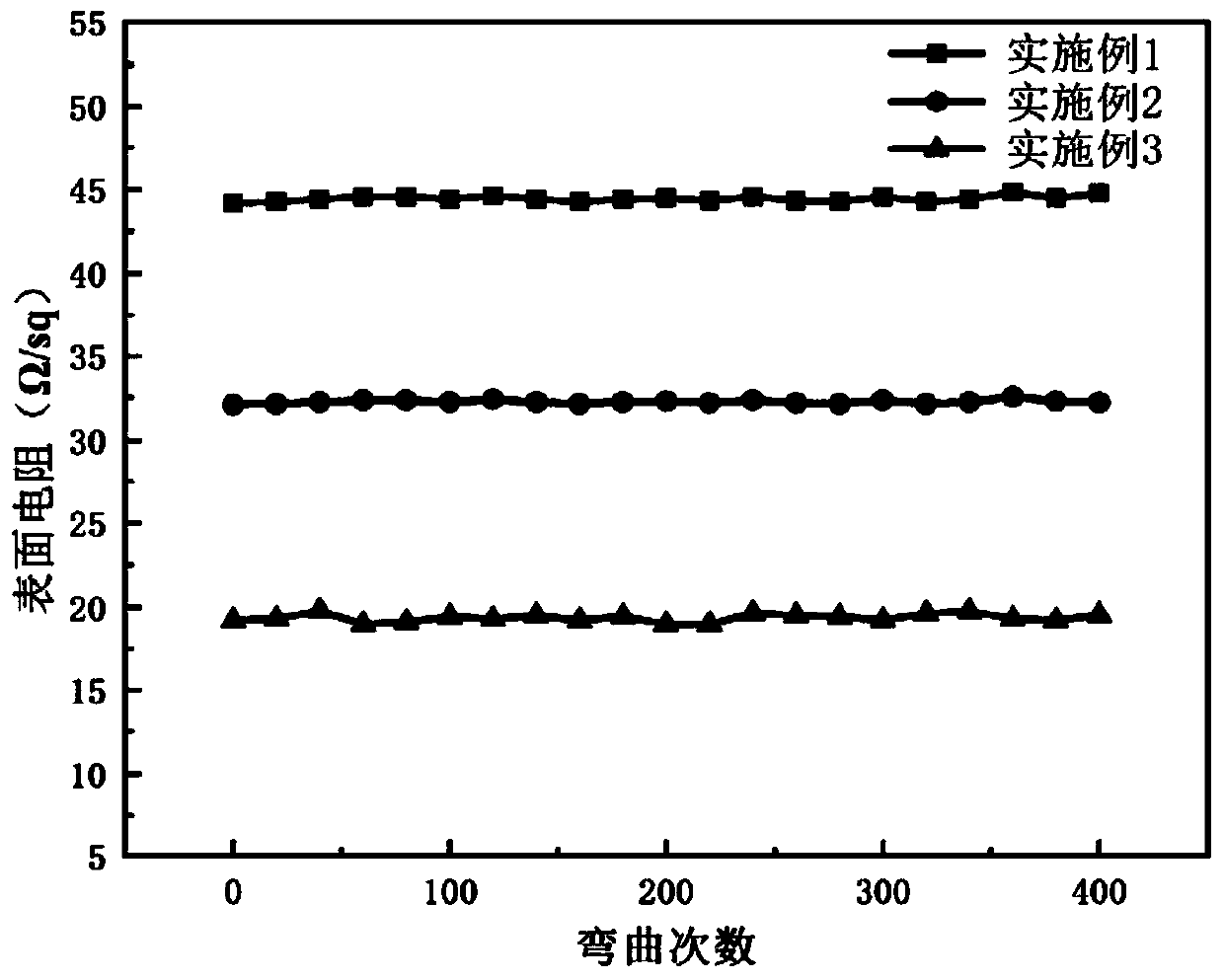

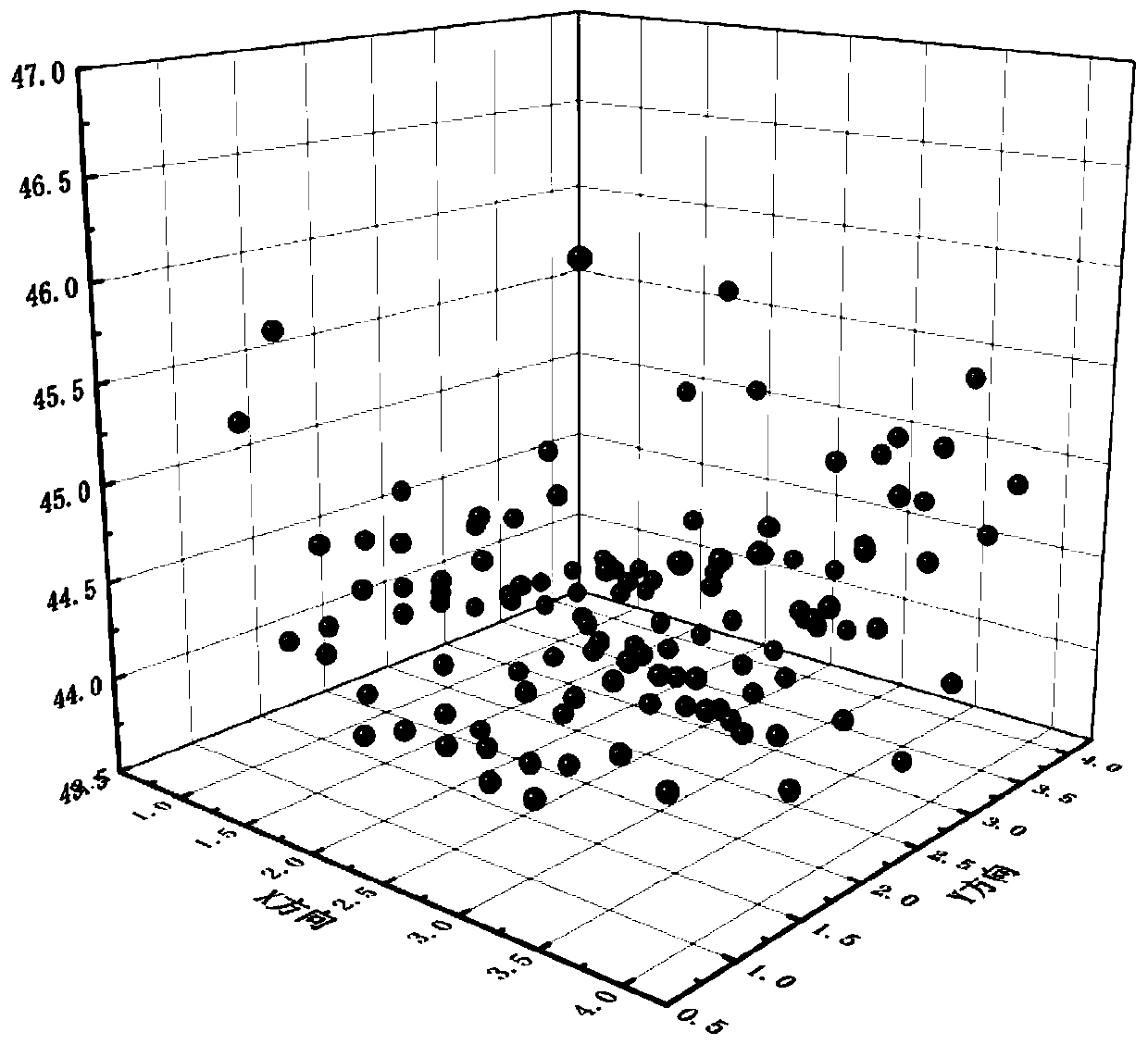

Embodiment 1

[0029] (1) Add 1 mg of silver nanowires to 100 ml of absolute ethanol, and disperse evenly by ultrasonication. Take 20 ml of the above-mentioned dispersion solution and filter it to the surface of a polytetrafluoroethylene filter membrane with a diameter of 5 cm, and then dry the filter membrane at room temperature for 2 hours. A uniformly dispersed silver nanowire film is obtained, and the deposition amount of silver nanowire on the film surface is 100mg / m 2 .

[0030] (2) Mix the liquid silicone rubber dihydroxypolydimethylsiloxane and the corresponding crosslinking agent methyltriethoxysilane according to the mass ratio of 100:2, and then rotate the mixture evenly at a speed of 2000rpm Spread it on the surface of tin foil, and then cure the film at 40°C for 24h.

[0031] (3) The side of the sample prepared in (1) with silver nanowires and the side with cured silicone rubber in (2) are closely attached, and the two attached samples are treated under 1MPa pressure for 24h. ...

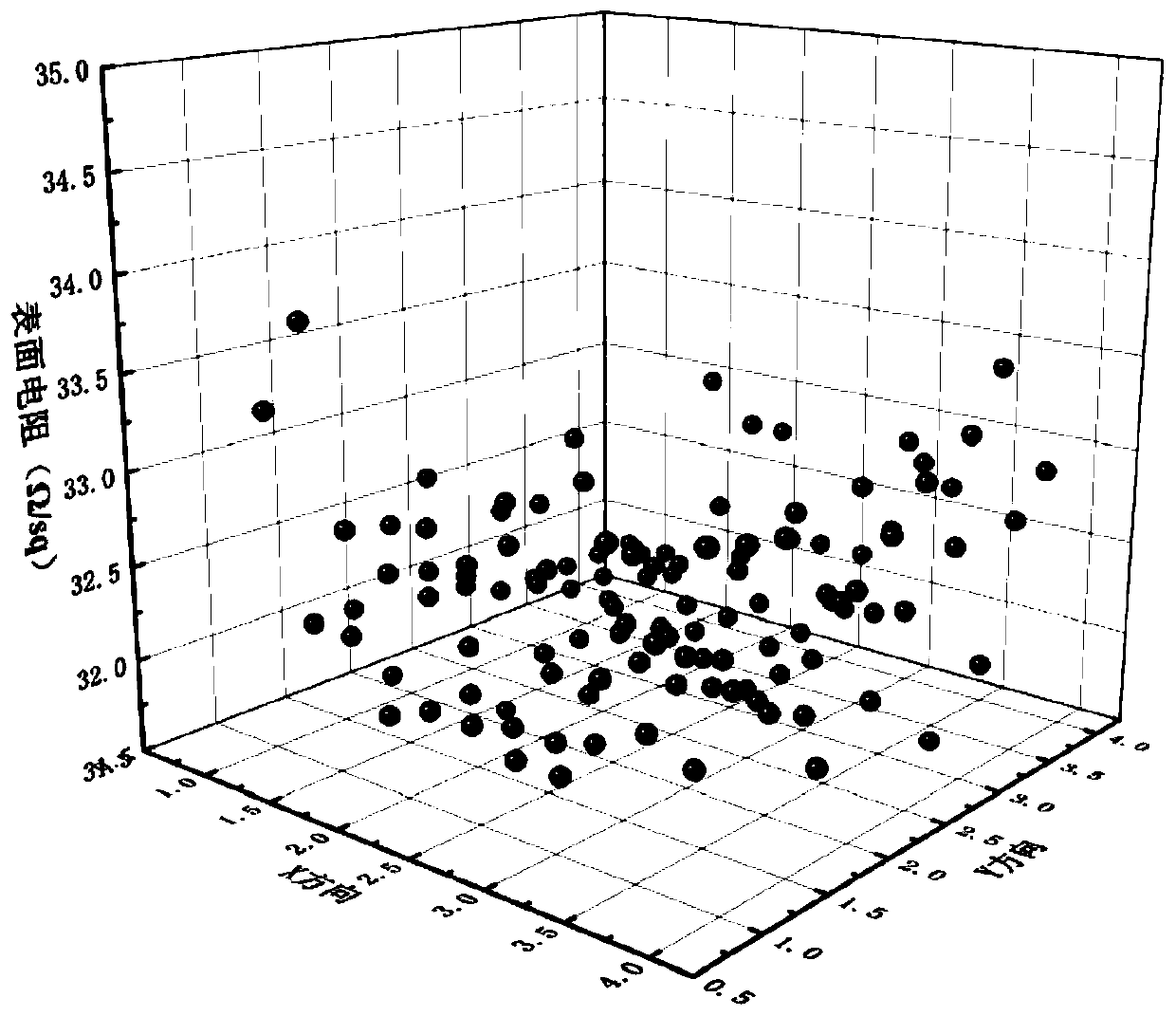

Embodiment 2

[0039] (1) Add 1 mg of silver nanowires to 100 ml of absolute ethanol, and disperse evenly by ultrasonication. Take 60 ml of the above-mentioned dispersion solution and filter it to the surface of a polytetrafluoroethylene filter membrane with a diameter of 5 cm, and then dry the filter membrane at room temperature for 4 hours. Obtain uniformly dispersed silver nanowire film (silver nanowire deposition amount on film surface is 300mg / m 2 ).

[0040] (2) Mix the liquid silicone rubber dihydroxypolydimethylsiloxane and the corresponding crosslinking agent methyltriethoxysilane according to the mass ratio of 100:6, and then rotate the mixture evenly at a speed of 4000rpm Spread it on the surface of tin foil, and then cure the film at 60°C for 18h.

[0041] (3) The side of the sample prepared in (1) with silver nanowires and the side with cured silicone rubber in (2) are closely bonded, and the two bonded samples are treated under 3MPa pressure for 18h, and then Transfer the sil...

Embodiment 3

[0049] (1) Add 1 mg of silver nanowires to 100 ml of absolute ethanol, and disperse evenly by ultrasonication. The above-mentioned dispersion liquid is vacuum filtered to the surface of a polytetrafluoroethylene filter membrane with a diameter of 5 cm, and then the filter membrane is dried at room temperature for 6 hours to obtain Uniformly dispersed silver nanowire film (silver nanowire deposition on the film surface is 500mg / m 2 ).

[0050](2) Mix the liquid silicone rubber dihydroxypolydimethylsiloxane and the corresponding crosslinking agent methyltriethoxysilane according to the mass ratio of 100:10, and then rotate the mixture evenly at a speed of 6000rpm Spread it on the surface of tin foil, and then cure the film at 80°C for 12h.

[0051] (3) The side of the sample prepared in (1) with the silver nanowires and the side with the cured silicone rubber in (2) are closely bonded, and the two bonded samples are treated for 12 hours under a pressure of 5 MPa. Transfer the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com