Composite acid fracturing method for supporting front edge of fracture by utilizing phase change material

A phase change material and composite acid fracturing technology, which is applied in earth-moving drilling, production fluids, wellbore/well components, etc., can solve the problems of difficult injection, high injection pressure, and large equipment wear, and achieves improved effective working distance, The effect of low injection pressure and simple injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

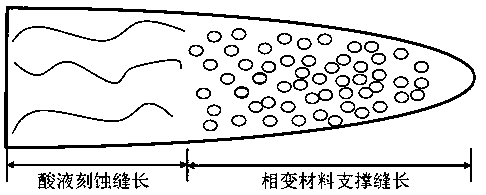

[0039] Such as figure 1 As shown, a composite acid fracturing method using phase change materials to support the fracture front includes the following steps:

[0040] (1) Select the reverse phase change material;

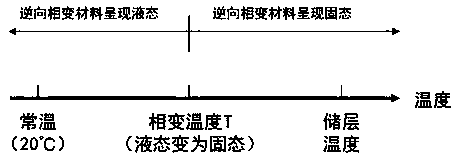

[0041] The phase transition temperature of the material is T, 20°C < T < reservoir temperature, the material is in a liquid state at room temperature Changing temperature T, it will change from liquid to solid and will not be broken under reservoir pressure conditions.

[0042] (2) Inject pre-fracturing fluid;

[0043] Inject the pre-fracturing fluid into the reservoir at an injection pressure higher than the fracture pressure of the reservoir rock, and the pre-fracturing fluid will open the reservoir to form hydraulic fractures. At the same time, the pre-fracturing fluid will also reduce the temperature of the reservoir to the reverse The phase change temperature T of the phase change material is below.

[0044] (3) Inject the mixed liquid of liquid reverse pha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com