A polyolefin resin-based carbon fiber suspension sizing agent and a preparation method thereof

A polyolefin resin, suspension technology, applied in carbon fiber, fiber processing, textiles and papermaking, etc., can solve the problems of low economic efficiency, poor stability, difficult preparation, etc., achieve good amphiphilicity, avoid aging and hardening, and improve stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

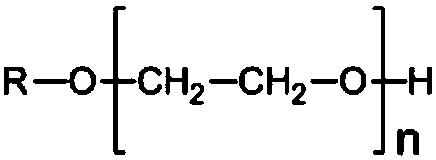

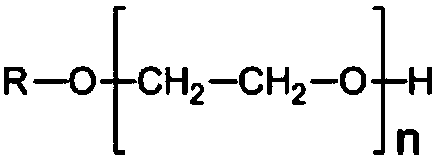

[0035] Put the quantitative polypropylene resin powder and sodium polyacrylate into the stirring tank A in sequence, and gradually add deionized water dropwise. When the amount of water added reaches 30wt% of the total feeding amount, start the mechanical stirring, continue stirring at a certain speed, and continue to add the remaining amount After stirring for a certain period of time, a uniform white emulsion is obtained, and the material is discharged and transferred to the stirred tank B equipped with a high-speed emulsifier, a certain amount of fatty alcohol polyoxyethylene ether is added, the high-speed emulsifier is turned on, and the stirring is continued at a fixed speed. The milky white suspension sizing agent was obtained by discharging.

[0036] The polypropylene resin powder is from China Petrochemical Co., Ltd., and the sodium polyacrylate and fatty alcohol polyoxyethylene ether are from BASF Corporation. The solid components of the suspension sizing agents prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com