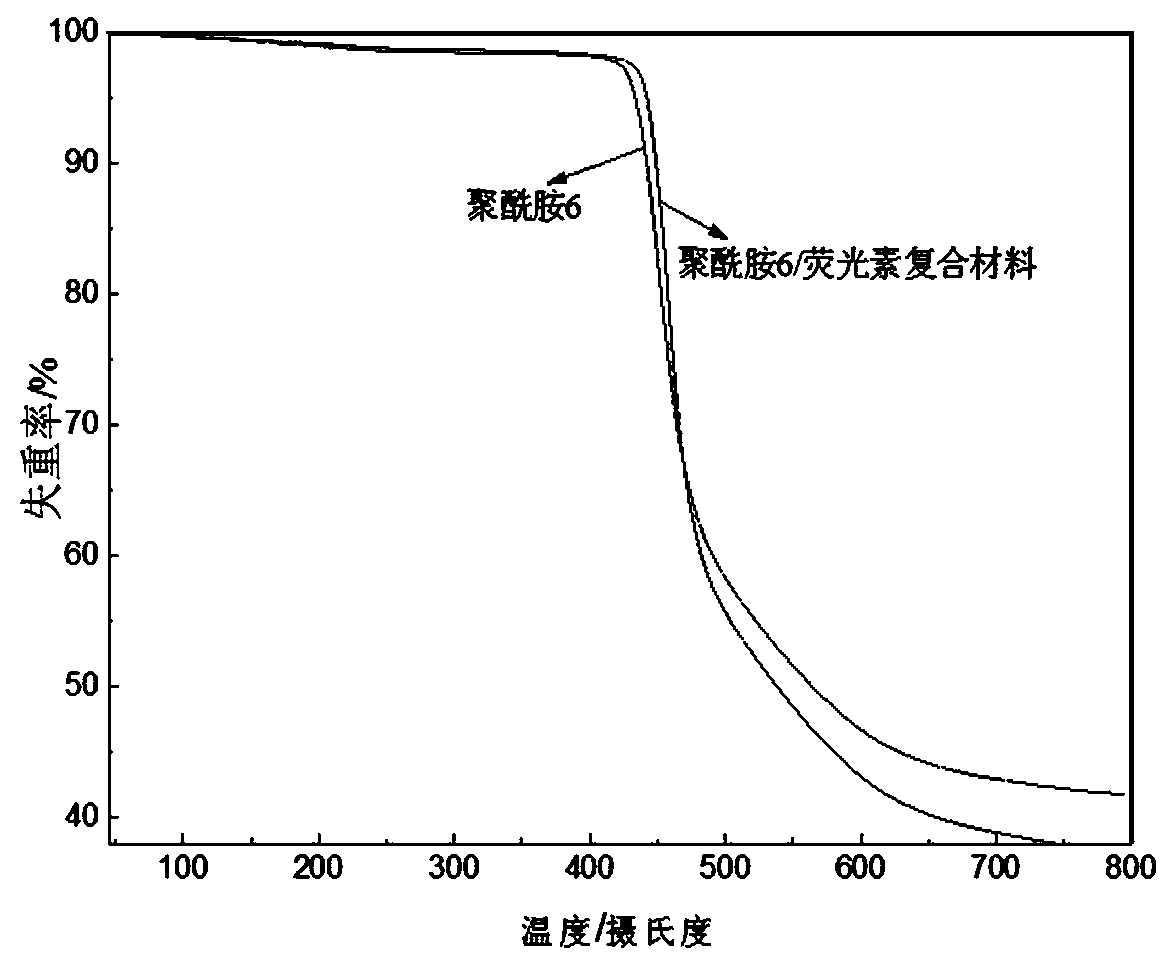

Polyamide 6/fluorescein compound material and production method thereof

A composite material and fluorescein technology, which is applied in the field of polyamide 6/fluorescein composite material and its preparation, can solve the problems of "poor dimensional stability, high water absorption rate, etc., and achieve performance parameter improvement, performance improvement, and good performance improvement effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] The polyamide 6 / fluorescein composite material provided in this example is prepared by in-situ polymerization. During the preparation process, fluorescein is used as a filler and adipic acid is used as a catalyst. The specific preparation process is as follows:

[0035] (1) Add 100 g of ε-caprolactam, 2 mL of distilled water, 1.0 g of adipic acid, and fluorescein (0.1 g, 0.3 g, 0.5 g, 0.7 g, and 0.9 g of fluorescein) into a three-necked flask, and heat Melt magnetic stirring, raise the system from room temperature to 190°C, and reflux for 3 hours;

[0036] (2) After the reaction in step (1) is completed and the water vapor is released, the temperature of the system is raised to 230°C within 0.5 hours, and then the temperature of the system is gradually raised to 260°C within 1.5 hours;

[0037] Keep this temperature, vacuumize gradually to -0.08MPa, vent, and cast into dumbbell-shaped samples while hot to test the tensile strength of the material, and cast into "V"-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com