Self-lubricating ceramic cutting tool material added with metal-coated nano-solid lubricant composite powder and preparation method thereof

A technology of solid lubricants and composite powders, which is applied in the direction of metal material coating technology, lubricating compositions, liquid chemical plating, etc., can solve the problem of large differences in anti-friction and wear resistance of self-lubricating ceramic tools and weakening of self-lubricating ceramics. Improve the mechanical properties and wear resistance, good sintering density and high bonding strength to improve the cutting performance of cutting tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

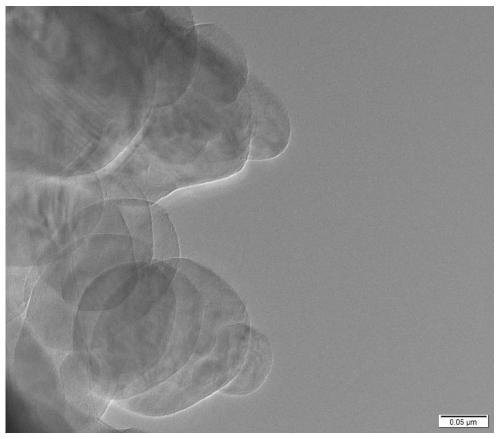

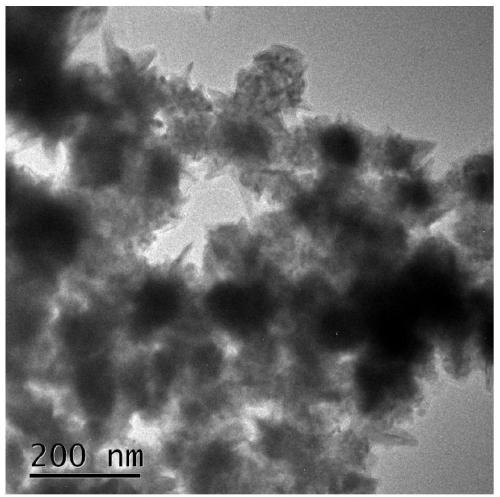

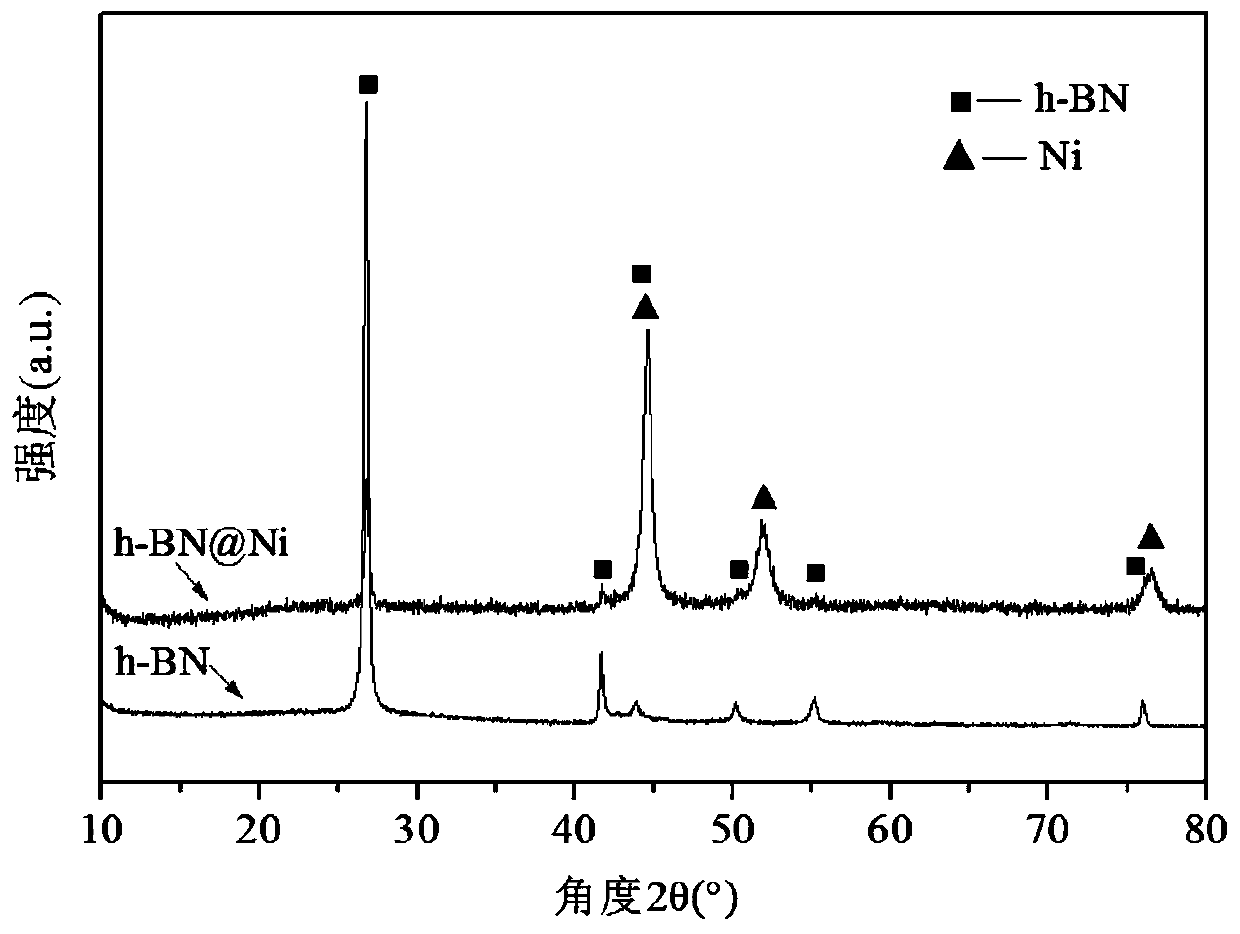

Image

Examples

Embodiment 1

[0063] Example 1: A self-lubricating ceramic tool material with metal-coated nano-solid lubricant composite powder, the mass percentage of each component is: α-Al 2 o 3 37%, (W,Ti)C 60.5%, h-BN n @Ni according to h-BN in composite powder n 1.5% by mass, MgO 0.5%, Y 2 o 3 0.5%.

[0064] The preparation steps are as follows:

[0065] (1) Weigh 1.5g NH 4 F, Add 100mL of distilled water, ultrasonically oscillate and stir to dissolve, slowly add 25mL of concentrated nitric acid under the condition of ultrasonic oscillating and stirring, add distilled water to 150mL, then add 1.5mg of polyvinylpyrrolidone, ultrasonically oscillate and stir to dissolve, and obtain a rough solution . Weigh 1.5g h-BN n Add the powder into the coarsening solution, ultrasonically shake for 30 minutes, and wash with distilled water to neutral after centrifugation to obtain roughened h-BN n Powder.

[0066] (2) Weigh 12g SnCl 2 2H 2 O and 2g Na 2 SnO 3 ·3H 2 O, add 10mL concentrated hydroch...

Embodiment 2

[0082] Example 2: A self-lubricating ceramic tool material with metal-coated nano-solid lubricant composite powder added, the mass percentage of each component is: α-Al 2 o 3 35%, (W,Ti)C 61%, h-BN n @Ni according to h-BN in composite powder n 3% by mass, MgO 0.5%, Y 2 o 3 0.5%.

[0083] The preparation steps are as follows:

[0084] (1) Weigh 9g NH 4 F, Add 400mL of distilled water, ultrasonically oscillate and stir to dissolve, slowly add 120mL of concentrated nitric acid under the conditions of ultrasonic oscillation and stirring, add distilled water to 600mL, then add 9mg of polyvinylpyrrolidone, ultrasonically oscillate and stir to dissolve, and obtain a rough solution. Weigh 3g h-BN n Add the powder into the coarsening solution, ultrasonically shake for 40 minutes, and wash with distilled water after centrifugation until neutral to obtain roughened h-BN n Powder.

[0085] (2) Weigh 30g SnCl 2 2H 2 O and 6g Na 2 SnO 3 ·3H 2 O, add 24mL of concentrated hydr...

Embodiment 3

[0097] Example 3: A self-lubricating ceramic tool material with metal-coated nano-solid lubricant composite powder added, the mass percentage of each component is: α-Al 2 o 3 38%, (W,Ti)C 56%, h-BN n @Ni according to h-BN in composite powder n 5% by mass, MgO 0.5%, Y 2 o 3 0.5%.

[0098] The preparation steps are as follows:

[0099] (1) Weigh 16g NH 4 F, Add 500mL of distilled water, ultrasonically oscillate and stir to dissolve, slowly add 200mL of concentrated nitric acid under the conditions of ultrasonic oscillation and stirring, add distilled water to 800mL, then add 16mg of polyvinylpyrrolidone, ultrasonically oscillate and stir to dissolve, and obtain a rough solution. Weigh 5g h-BN n Add the powder into the coarsening solution, ultrasonically shake for 50 minutes, and wash with distilled water after centrifugation until neutral to obtain roughened h-BN n Powder.

[0100] (2) Weigh 45g SnCl 2 2H 2 O and 10g Na 2 SnO 3 ·3H 2 O, add 37.5mL of concentrated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com