Color siloxane end-capped aqueous polyurethane hair dye and preparation method thereof,

A water-based polyurethane and siloxane technology, applied in hair care, pharmaceutical formulations, cosmetic preparations, etc., can solve discoloration and other problems, and achieve the effects of large molecular weight, good styling effect, and high gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

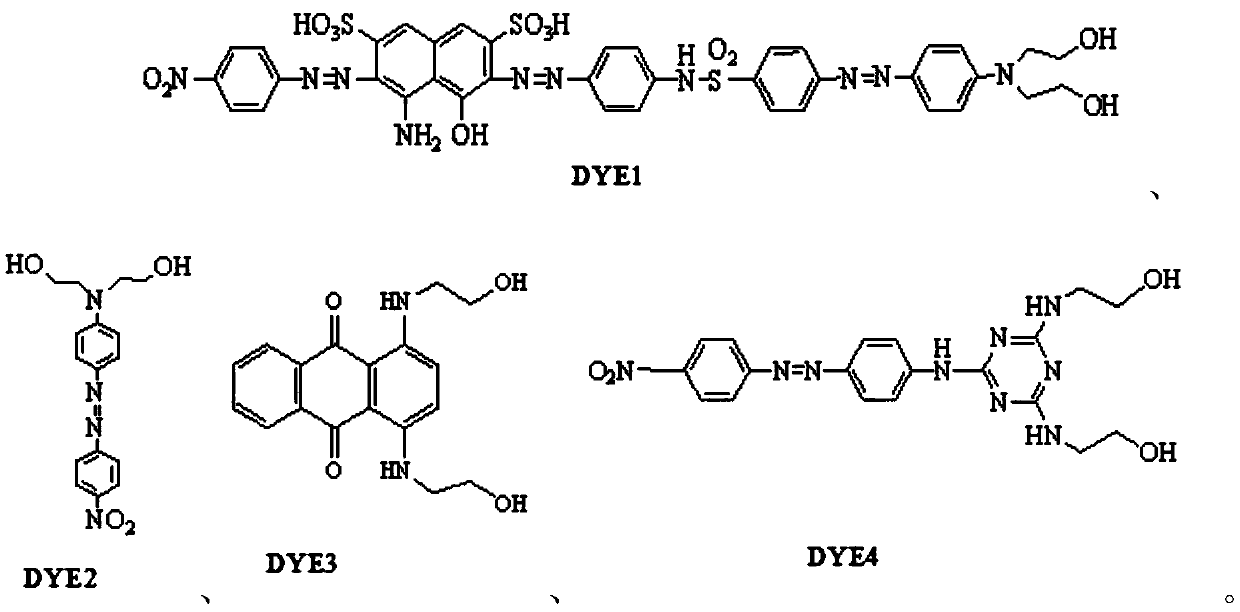

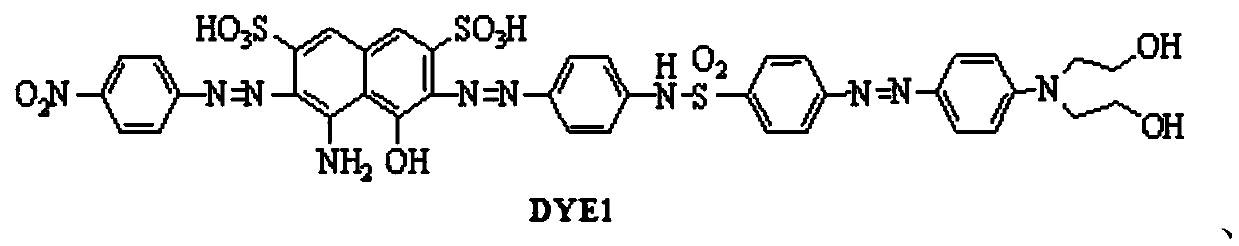

Embodiment 1

[0042] The number average molecular weight M n2000 polypropylene glycol (PPG) was dehydrated at 110°C for 2 hours, then cooled to 50°C, 40 grams was added to a 500mL three-necked flask, and 24 grams of isophorone diisocyanate (IPDI) was added to stir and the temperature was raised to 80 After reacting at ℃ for 2 hours, add 2 grams of DYE1, 0.1 grams of dibutyltin dilaurate (DBTDL), 5 grams of dimethylol propionic acid (DMPA), 3 grams of 1,4-butanediol (BDO) and 0.5 grams of trihydroxy Methylpropane (TMP) and 30 grams of acetone were stirred at 70°C for 4 hours and then cooled to 40°C; after adding 5 grams of KH-540 and reacting for 10 minutes, 3.7 grams of triethylamine (TEA) and 20 grams of acetone were added. After reacting for 5 minutes, add 200 grams of water under high-speed stirring (1200 rpm), and after stirring for 30 minutes, transfer the reaction product to a rotary evaporator, and remove acetone at 45°C and 0.01MPa vacuum to obtain black silicon oxide Alkane-termin...

Embodiment 2

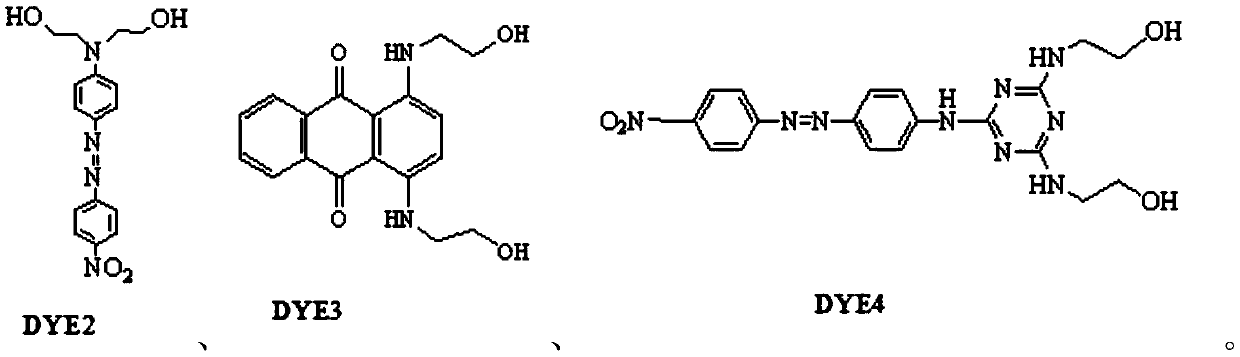

[0047] The number average molecular weight M n 2000 polypropylene glycol (PPG) was dehydrated at 110°C for 2 hours, then cooled to 50°C, 40 grams was added to a 500mL three-necked flask, and 24 grams of isophorone diisocyanate (IPDI) was added to stir and the temperature was raised to 80 After reacting at ℃ for 2 hours, add 2 grams of DYE2, 0.1 grams of dibutyltin dilaurate (DBTDL), 5 grams of dimethylol propionic acid (DMPA), 3 grams of 1,4-butanediol (BDO) and 1 gram of trihydroxy Methylpropane (TMP) and 30 grams of acetone were stirred at 70°C for 4 hours and then cooled to 40°C; after adding 5 grams of KH-792 and reacting for 30 minutes, 3.7 grams of triethylamine (TEA) and 20 grams of acetone were added. After reacting for 5 minutes, add 200 grams of water under high-speed stirring (1200 rpm), and after stirring for 30 minutes, transfer the reaction product to a rotary evaporator, and remove acetone at 45°C and 0.01MPa vacuum to obtain red silica Alkane modified water-ba...

Embodiment 3

[0051] The number average molecular weight M n 2000 polypropylene glycol (PPG) was dehydrated at 110°C for 2 hours, then cooled to 50°C, 40 grams was added to a 500mL three-necked flask, and 24 grams of isophorone diisocyanate (IPDI) was added to stir and the temperature was raised to 80 After reacting at ℃ for 2 hours, add 2 grams of DYE3, 0.1 grams of dibutyltin dilaurate (DBTDL), 5 grams of dimethylolpropionic acid (DMPA), 3 grams of 1,4-butanediol (BDO) and 1 gram of trihydroxy Methylpropane (TMP) and 30 grams of acetone were stirred at 70°C for 4 hours and then cooled to 40°C; after adding 5 grams of KH-602 and reacting for 40 minutes, 3.7 grams of triethylamine (TEA) and 20 grams of acetone were added. After reacting for 5 minutes, add 200 grams of water under high-speed stirring (1200 rpm), and after stirring for 30 minutes, transfer the reaction product to a rotary evaporator, and remove acetone at 45°C and 0.01MPa vacuum to obtain blue silicon Oxyalkylene modified wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com