Antibacterial and wear-resistant invisible brace

A technology of invisible braces and dammar resin, applied in dentistry, dental preparations, dental prostheses, etc., can solve problems such as inability to achieve invisible effect, black color of braces, and oral discomfort, so as to avoid breeding bacteria, improve strength and smoothness Degree, improve the effect of antibacterial and abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

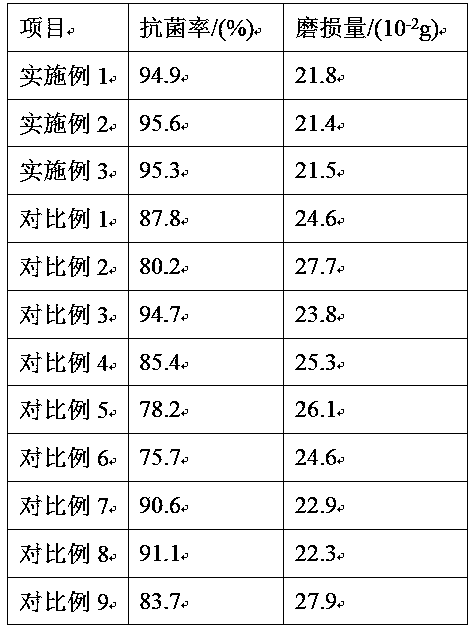

Examples

Embodiment 1

[0019] An antibacterial and wear-resistant invisible braces, made of the following raw materials in parts by weight: modified dammar resin 87, polyurethane resin 65, stearic acid 14, Ag-tricalcium phosphate 11, carboxymethyl cellulose sodium 8, nano-oxidized Zinc 3, nano titanium dioxide 2, polyhexamethylene guanidine 2.

[0020] For the modified dammar resin, heat the dammar resin to 130°C, stir until fully melted, then add 0.7% salt by weight of the dammar resin, heat and stir for 30 minutes, then add 1.2% paraben by weight of the dammar resin Methyl ester, stirred evenly under vacuum, cooled at 1°C to 90°C, kept at temperature for 10 minutes, and cooled down to room temperature naturally to obtain modified dammar resin.

[0021] For the Ag-tricalcium phosphate, tricalcium phosphate is ball-milled to 40-50 nm, heated to 640°C, kept for 15 minutes, vacuumed to -52kPa, and a colorless and transparent solution with a concentration of 5% by weight of tricalcium phosphate of 260 ...

Embodiment 2

[0029] An antibacterial and wear-resistant invisible dental brace, made of the following raw materials in parts by weight: modified dammar resin 89, polyurethane resin 66, stearic acid 15, Ag-tricalcium phosphate 12, carboxymethyl cellulose sodium 9, nano-oxidized Zinc 3.5, nano titanium dioxide 2.5, polyhexamethylene guanidine 2.5.

[0030] For the modified dammar resin, heat the dammar resin to 135°C, stir until fully melted, then add 0.8% salt by weight of the dammar resin, heat and stir for 35 minutes, then add 1.3% paraben by weight of the dammar resin Methyl ester, stirred evenly under vacuum, cooled at 1.5°C to 95°C, kept at temperature for 13 minutes, and cooled down to room temperature naturally to obtain modified Darmar resin.

[0031] For the Ag-tricalcium phosphate, tricalcium phosphate is ball milled to 45nm, heated to 660°C, kept for 18min, vacuumed to -53kPa, and colorless and transparent nano-silver with a concentration of 6% by weight of tricalcium phosphate a...

Embodiment 3

[0039] An antibacterial and wear-resistant invisible braces, made of the following raw materials in parts by weight: modified dammar resin 91, polyurethane resin 67, stearic acid 16, Ag-tricalcium phosphate 13, carboxymethyl cellulose sodium 10, nano-oxidized Zinc 4, nano titanium dioxide 3, polyhexamethylene guanidine 3.

[0040] For the modified dammar resin, heat the dammar resin to 140°C, stir until fully melted, then add 0.9% salt by weight of dammar resin, heat and stir for 40min, then add 1.4% paraben by weight of dammar resin Methyl ester, stirred evenly under vacuum, cooled at 2°C to 100°C, kept for 15 minutes, and naturally cooled to room temperature to obtain modified dammar resin.

[0041] For the Ag-tricalcium phosphate, tricalcium phosphate is ball-milled to 50 nm, heated to 680° C., kept for 20 minutes, vacuumed to -54 kPa, and colorless and transparent nano-silver with a concentration of 300 mg / L of 7% by weight of tricalcium phosphate is added. The solution w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com