Work time adjusting system for electric steam box

A technology of working time and adjustment system, applied in the field of electric steamer, can solve the problem that the setting of steaming time depends on manual experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

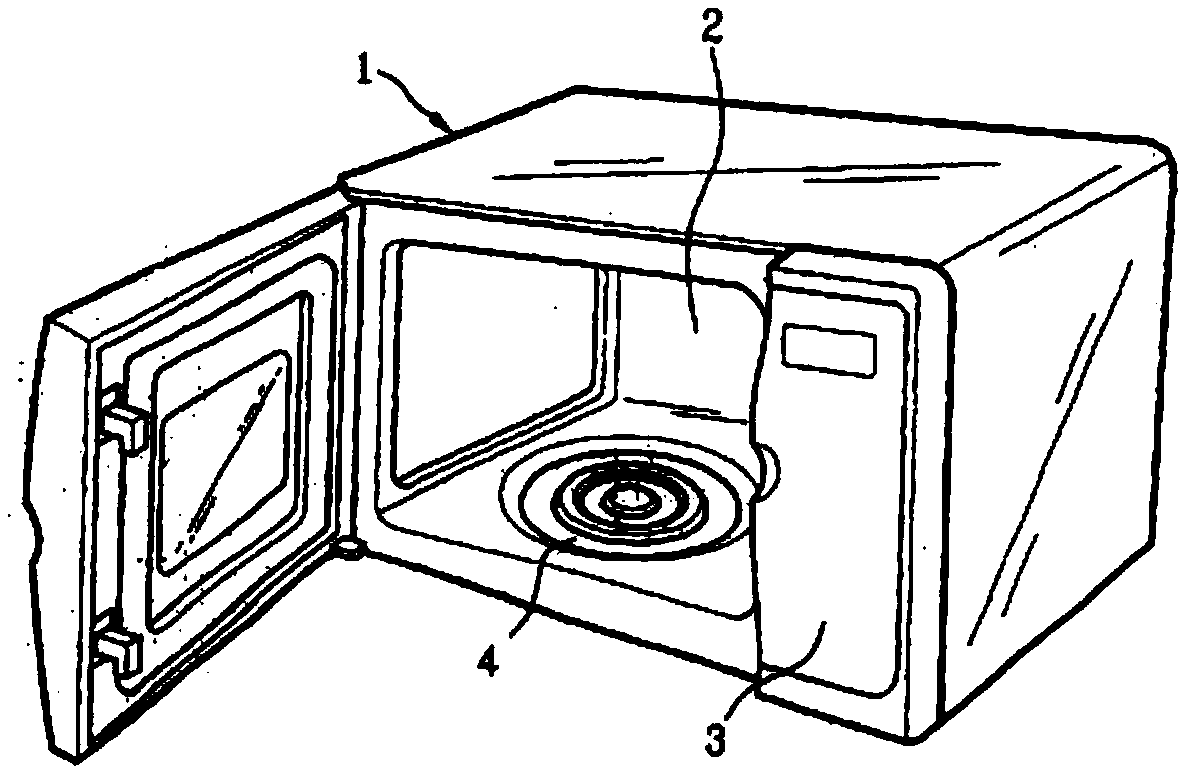

Image

Examples

Embodiment Construction

[0010] The implementation of the system for adjusting the working time of the electric steamer of the present invention will be described in detail below with reference to the accompanying drawings.

[0011] The electric steamer can be controlled by mechanical buttons; the Teflon heating plate is raised, which takes up space and is easy to cause water to flow out; a water outlet pipe drips water into the heating plate; the water supply method is a water pump; the plastic is covered with iron Non-removable hinges; single layer steamed. The electric steamer adopts an advanced dynamic balance water supply system. The biggest advantage of this system is that the water supply is accurate, there will be no problem of too much or too little water, and the water level can be continuously maintained at three quarters of the heating plate.

[0012] Because the heating of the electric steamer is traditional, it uses pure steam to heat, so the speed is not as fast as the microwave oven. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com