Substrate for semiconductor device, semiconductor device, and method for manufacturing substrate for semiconductor device

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, transistors, etc., can solve problems such as current collapse, buffer layer crystallinity reduction, easy deterioration, etc., and achieve the effect of suppressing current collapse phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0111] Hereinafter, although an Example is shown and this invention is demonstrated more concretely, this invention is not limited to this.

[0112] [Example]

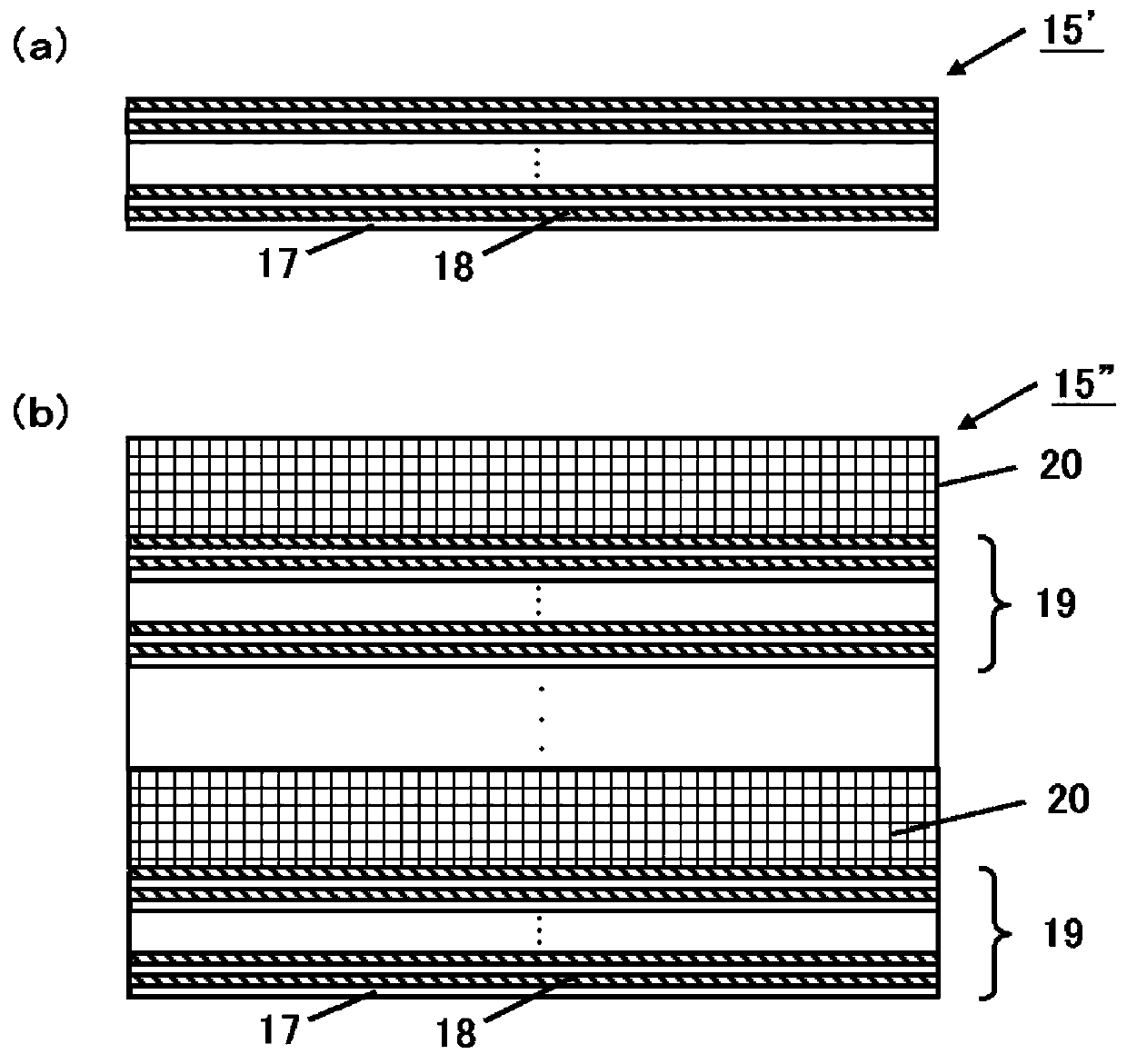

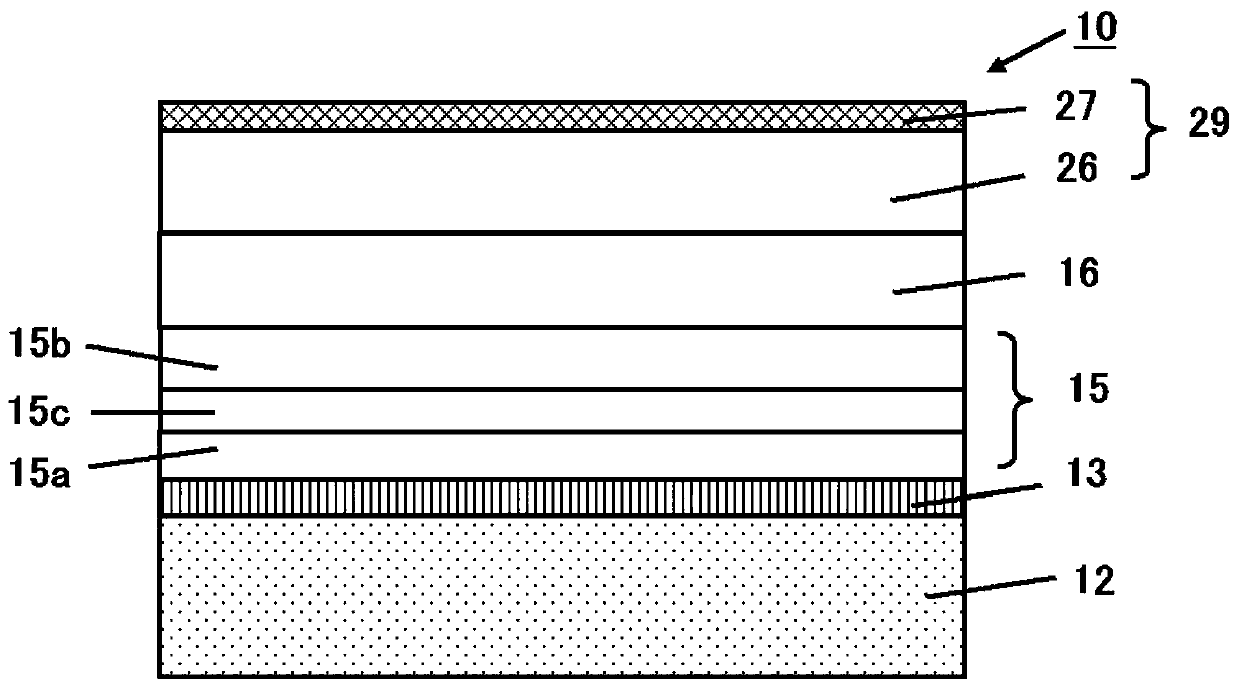

[0113] use for Figure 5 and Image 6 The method for manufacturing a substrate for a semiconductor device described above produces a substrate for a semiconductor device. However, as the initial layer, an initial layer 13 made of AlN is formed on the substrate 12, and an Fe-doped layer (iron concentration: 1×10 18 atoms / cm 3 above) as the first region 15a. The first area 15a is as figure 2 The laminate structure shown in (b) is a laminate structure in which eight pairs of AlN layers 17 and GaN layers 18 are laminated alternately, and six pairs of GaN insertion layers 20 are alternately laminated.

[0114] An undoped (undope) Fe layer (without introducing Cp) is formed on the first region 15a. 2 Layers formed of Fe: the third region 15c and the second region 15b). The carbon concentration of the upper layer (se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com