Low-cost aluminum-based electrolyte and aluminum battery application thereof

A technology of electrolyte and aluminum-sulfur battery, applied in the field of electrolyte, can solve the problems of low coulombic efficiency, high production cost, and poor cycle life, and achieve the effects of high coulombic efficiency, low production cost, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] At room temperature, in an argon glove box, 1.3 times the amount of substance equivalent AlCl 3 Slowly added to acetamide, and magnetically stirred for 12 hours, a clear and transparent brown-yellow liquid was obtained, which was used as an electrolyte after standing still.

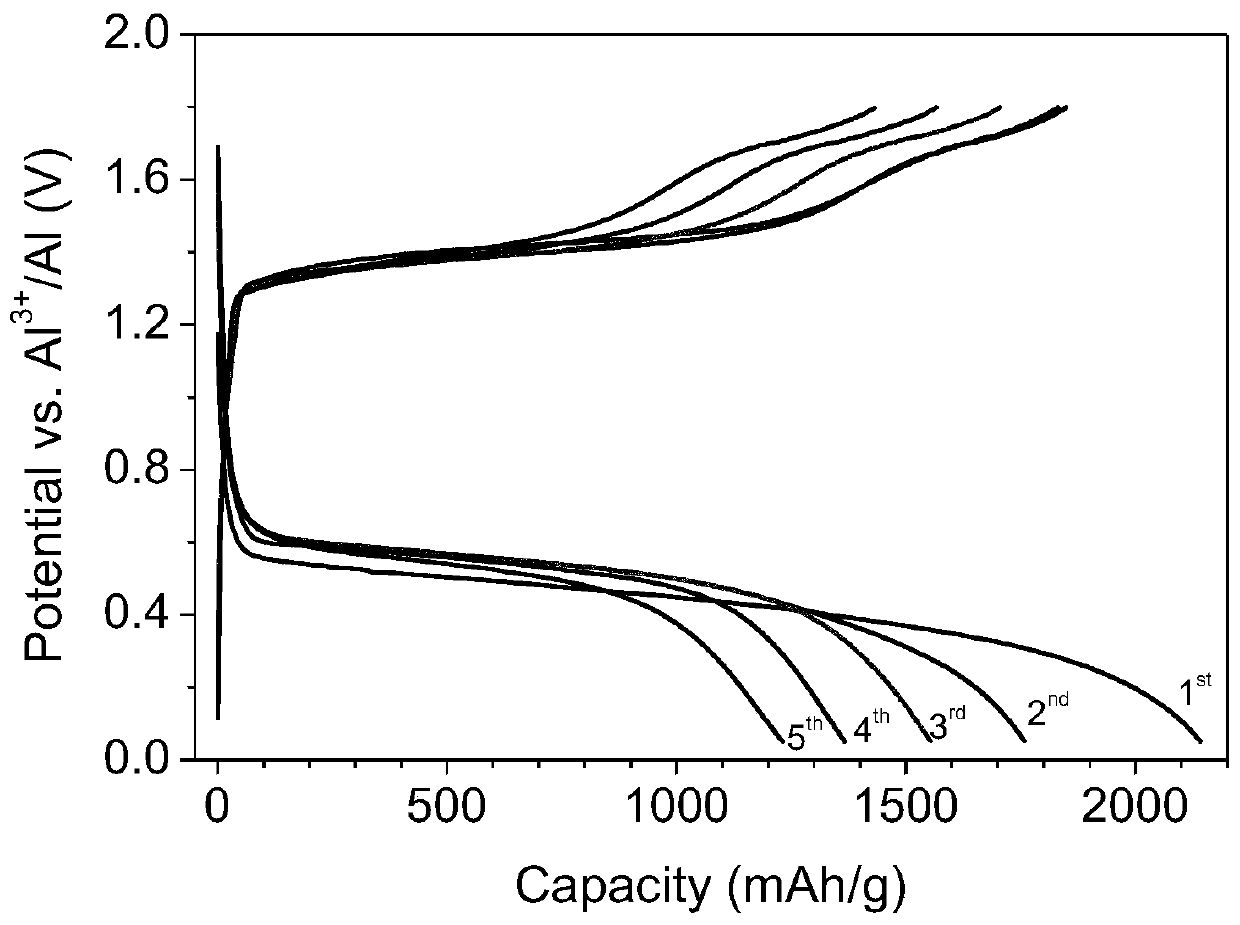

[0024] The above solution is used as the electrolyte, and S@mesoporous carbon (CMK-3 type) with a sulfur content of 50% is used as the positive electrode composite material. Mix and grind to make the positive pole piece, press the pole piece onto the molybdenum mesh of the positive current collector as the positive pole, use the washed and dried aluminum piece with a certain thickness and purity as the negative pole, and use the Whatman GF / A glass fiber diaphragm in argon gloves The cells in the Swagelok configuration were assembled in the box and then transferred out of the glove box. The battery was tested by cyclic voltammetry on a Solartron electrochemical workstation. Carry out the constant ...

Embodiment 2

[0026] According to the method of embodiment 1, the difference is that AlCl 3 Slowly add into acetamide according to the molar ratio of 1.2:1 to acetamide, and after it is completely dissolved, let it stand still and use it as an electrolyte.

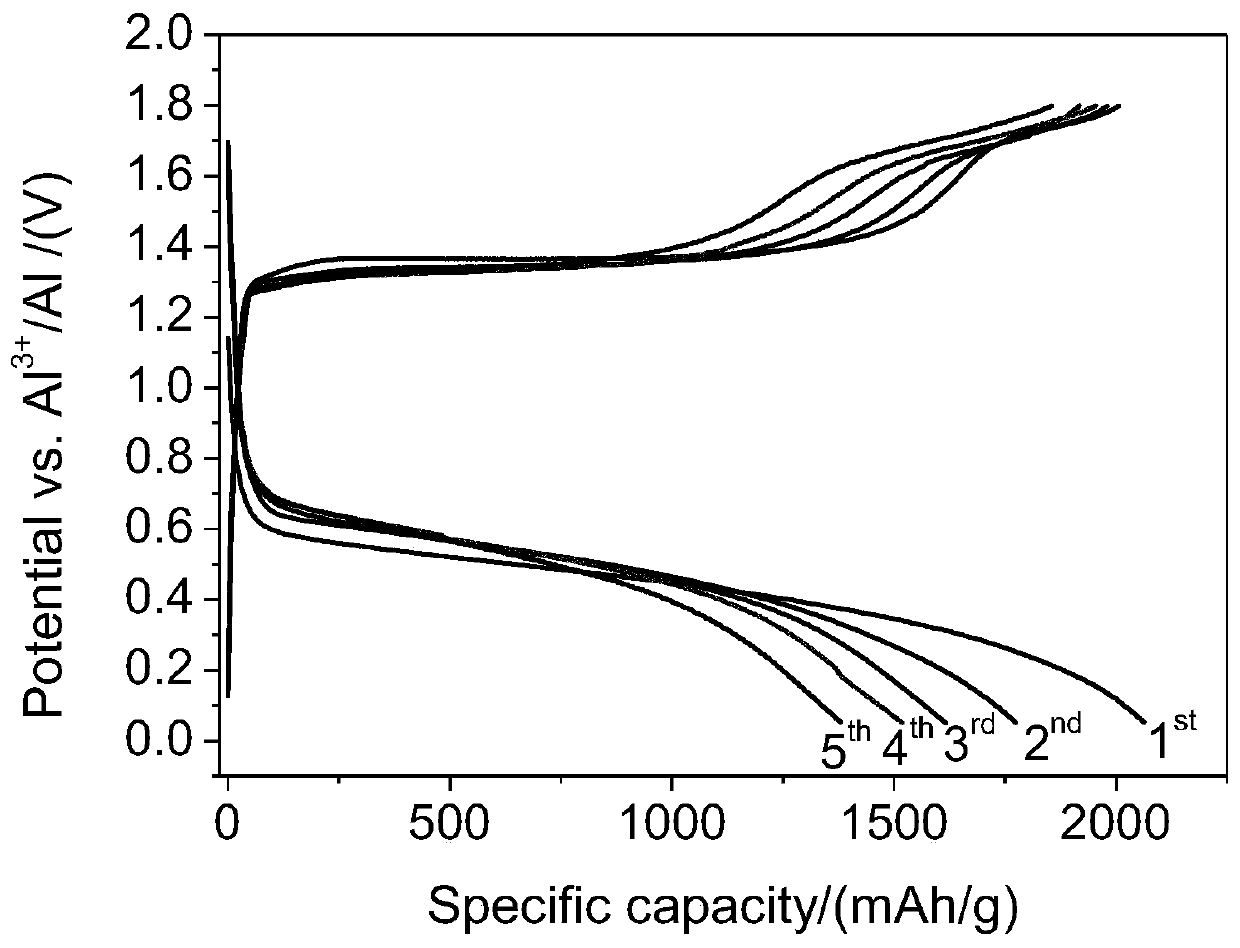

[0027] The pole piece making and battery assembly process are the same as in Example 1. The cyclic voltammetry test was carried out on the Solartron electrochemical workstation, and the constant current charge and discharge test was carried out on the LAND tester. The cut-off voltage was 0.05-1.8V, and the charge and discharge current was 100mA. The results showed that the specific capacity of the first discharge cycle reached 1250mAh·g –1 , the specific capacity after 20 cycles is 777mAh·g –1 .

Embodiment 3

[0029] According to the method of Example 1, the difference is that the Al(OTF) of mass fraction 2% is added in the obtained clear and transparent orange-yellow solution 3 Continue to stir as an additive, and after it is completely dissolved, let it stand still and use it as an electrolyte.

[0030] The eutectic liquid at room temperature was used as the electrolyte, and the pole piece production and battery assembly process were the same as in Example 1. And carry out the constant current charge and discharge test on the LAND tester, the cut-off voltage is 0.05-1.8V, the charge and discharge current is 100mA, the result shows that adding Al(OTF) 3 Coulombic efficiency increased from 84% to 90% after being used as an additive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com