Curved glass pattern processing method and system

A technology of curved glass and processing methods, which is applied in the direction of photolithography exposure devices, microlithography exposure equipment, etc., to achieve the effects of high product output rate, improved yield rate, and improved alignment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

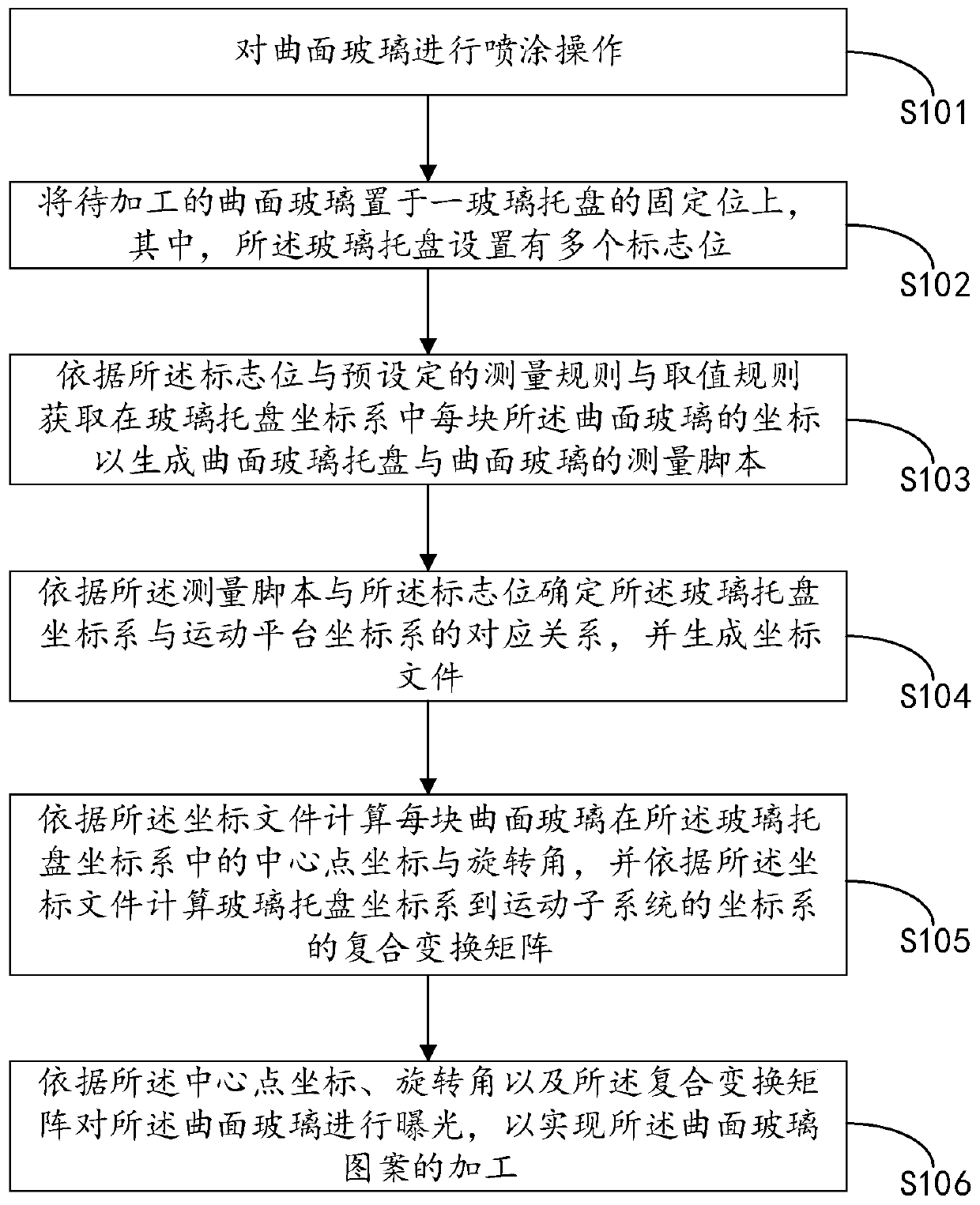

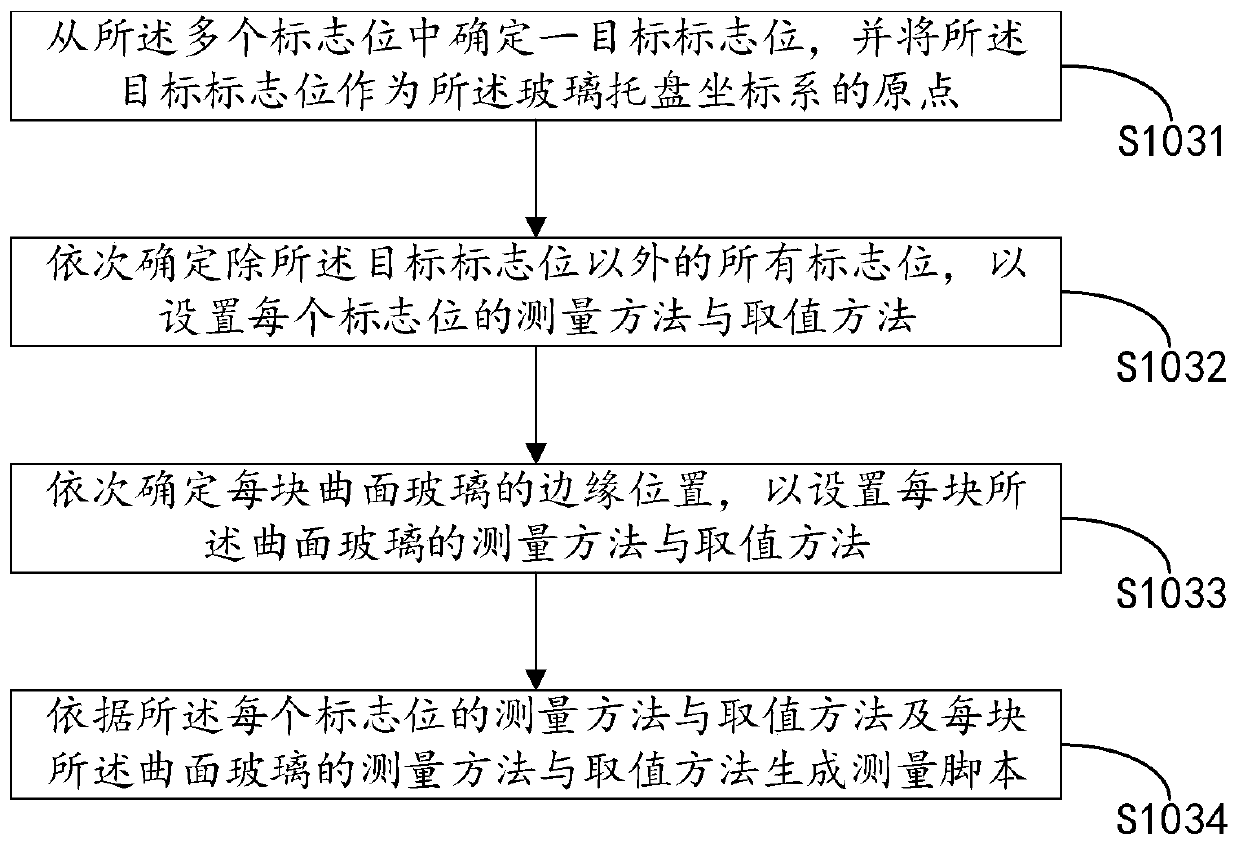

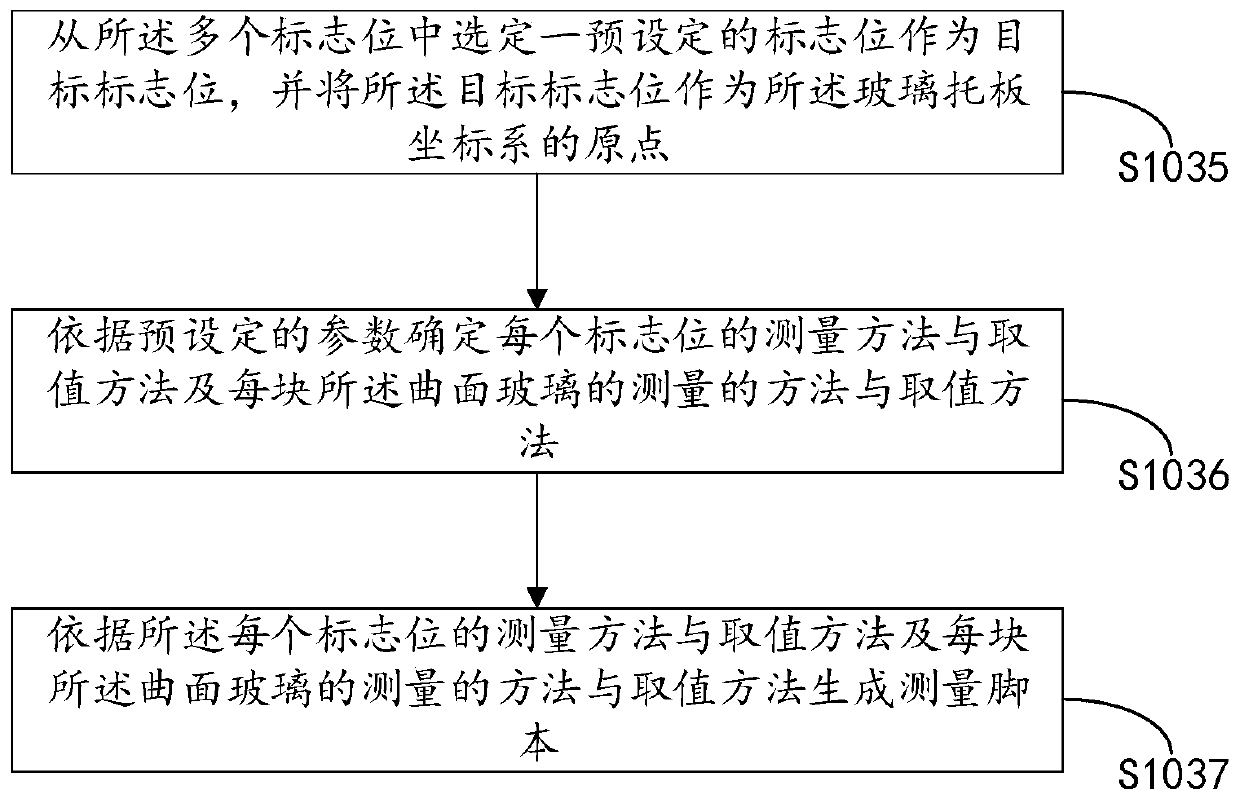

[0033] see figure 1 , an embodiment of the present invention provides a curved glass pattern processing method, which is applied to a curved glass pattern processing system 100, wherein the curved glass pattern processing system 100 includes a spraying machine 110, a glass tray 120, an exposure machine 140, a positioning device 130 and a control Device 150, through the curved glass pattern processing method provided in this embodiment, the construction cost of the entire curved glass pattern processing system 100 can be lower than that of the trial solution, the labor cost of input is less, the product output rate is high, and the product yield rate is greatly improved. promote.

[0034] Specifically, the curved glass pattern processing method includes:

[0035] S101, spraying the curved glass.

[0036] In this embodiment, photolithography is used to process patterns on the curved glass, so spraying is required first.

[0037] Specifically, the curved glass is first placed ...

no. 2 example

[0124] see Figure 6 , the embodiment of the present invention provides a curved glass pattern processing system 100, the curved glass pattern processing system 100 includes a spraying machine 110, a controller 150, a glass tray 120, a positioning device 130 and an exposure machine 140, wherein, this embodiment provides The curved glass pattern processing system 100 corresponds to the curved surface processing method described in the first embodiment, so please refer to the first embodiment for details not mentioned in this embodiment.

[0125] Specifically, the spraying machine 110 is used to spray the curved glass, and the glass tray 120 is used to fix the curved glass to be processed, wherein the glass tray 120 is provided with a plurality of marking positions.

[0126] The controller 150 is used to obtain the coordinates of each piece of curved glass in the coordinate system of the glass tray 120 according to the flag position and preset measurement rules and value-taking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com