High-temperature oxygen-rich supernormal-pressure strengthened combustion purification device for benzene harmful substances in industrial waste gas

A technology of industrial waste gas and purification equipment, which is applied in the direction of combustion method, combustion type, indirect carbon dioxide emission reduction, etc., which can solve the problems of huge equipment, high operating cost, and gas leakage of benzene, etc., and achieve strong heat preservation effect and low operating cost. low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

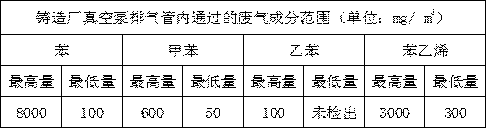

Problems solved by technology

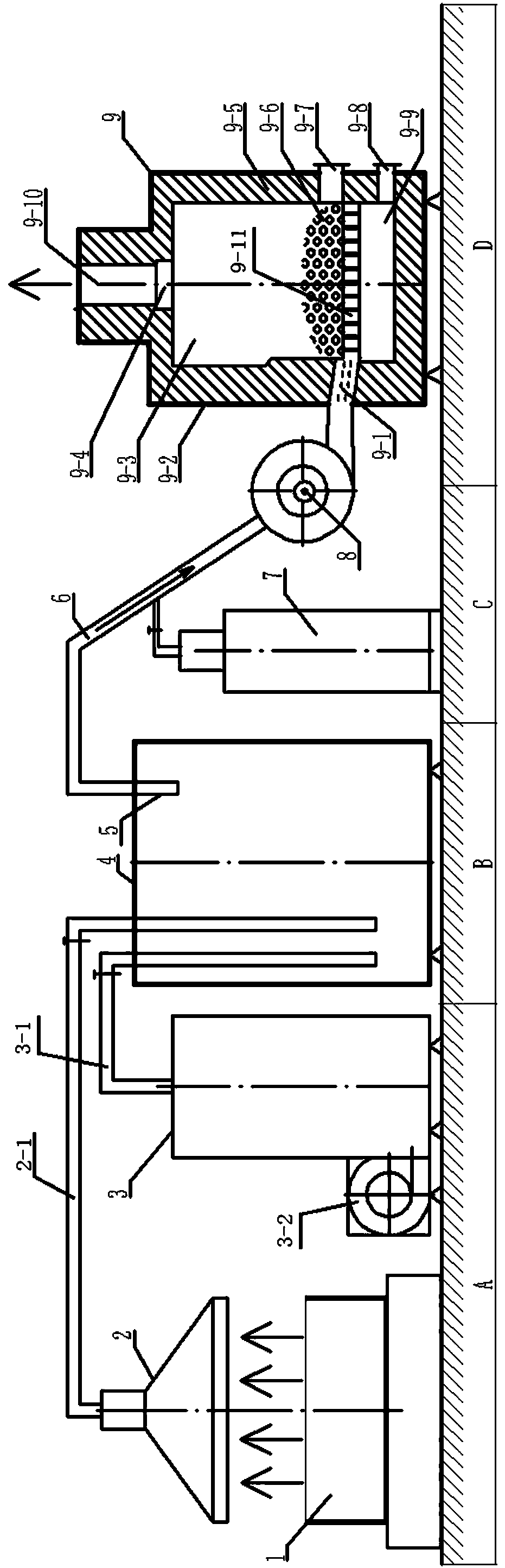

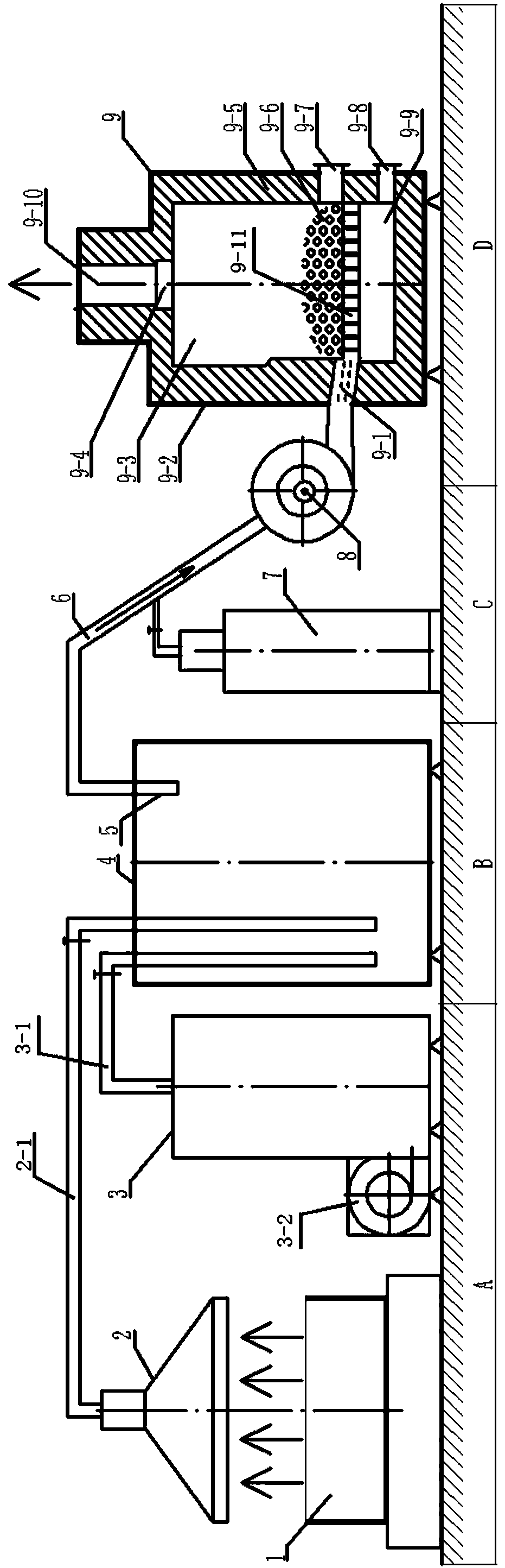

Method used

Image

Examples

Embodiment

[0059] A high-temperature oxygen-enriched supernormal pressure enhanced combustion purification method for benzene-type harmful substances in industrial waste gas, comprising the following steps:

[0060] 1) Collect waste gas containing benzene;

[0061] 2) Mix the exhaust gas with oxygen, and input 80g-200g of O per cubic meter of exhaust gas 2 mixed to form an oxygen-enriched gas mixture (O 2 O in the gas is higher than in the normal atmosphere 2 The content is "oxygen-enriched");

[0062] 3) The mixed gas is introduced into the combustion chamber above 1300°C, so that the exhaust gas fully reacts with oxygen in a turbulent and tumbling state in the combustion chamber with high temperature and oxygen-enriched atmosphere to generate CO 2 and H 2 O, get purified.

[0063] Step 1-1) is also included after step 1): introducing the exhaust gas into the storage and homogenization device, so that the concentration of the exhaust gas tends to be relatively uniform, which is ben...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com