Spliced seam reinforcing parts of comprehensive pipe rack formworks

A technology of comprehensive pipe gallery and reinforcement, applied in the field of joint reinforcement, can solve the problems of wrong platform, leakage of concrete, affecting appearance quality, etc., to reduce wrong platform, simple production process, reduce wrong platform and leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is further illustrated below by specific examples.

[0019] An anti-error platform method for jointing of formwork of comprehensive pipe gallery, including

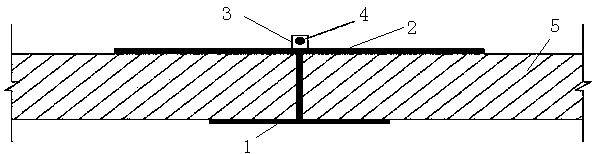

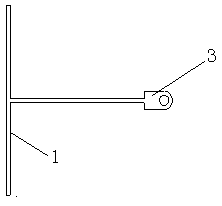

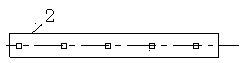

[0020] Step 1. Prepare reinforcements; the reinforcements include a core plate 1 and a pressure plate 2, wherein the core plate 1 includes a vertical brace and a bottom plate, and spaced stop lugs 3 are arranged at intervals along the length direction on the top of the vertical brace, and the center of the pressure plate 2 is along the There are through holes spaced apart in the length direction, and the distance between the through holes is the same as the distance between the limiting lugs 3 ;

[0021] Step 2. Stack the core plate 1 and the pressure plate 2 and insert the iron wire 4 into the hole on the pressure plate 2 to combine the core plate 1 and the pressure plate 2;

[0022] Step 3. Install the formwork 5. During the installation process of the formwork 5, install the reinforcing pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com