Method for simultaneously preparing vanadium pentoxide and chemical grade manganese dioxide by using chrome vanadium slag and low-grade pyrolusite

A technology of vanadium pentoxide and manganese dioxide, which is applied in the direction of improving process efficiency, can solve the problems of high processing cost and serious environmental pollution, and achieve improved leaching rate, high-efficiency separation, avoiding sodium roasting, water immersion and calcification The effect of roasting and acid leaching process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

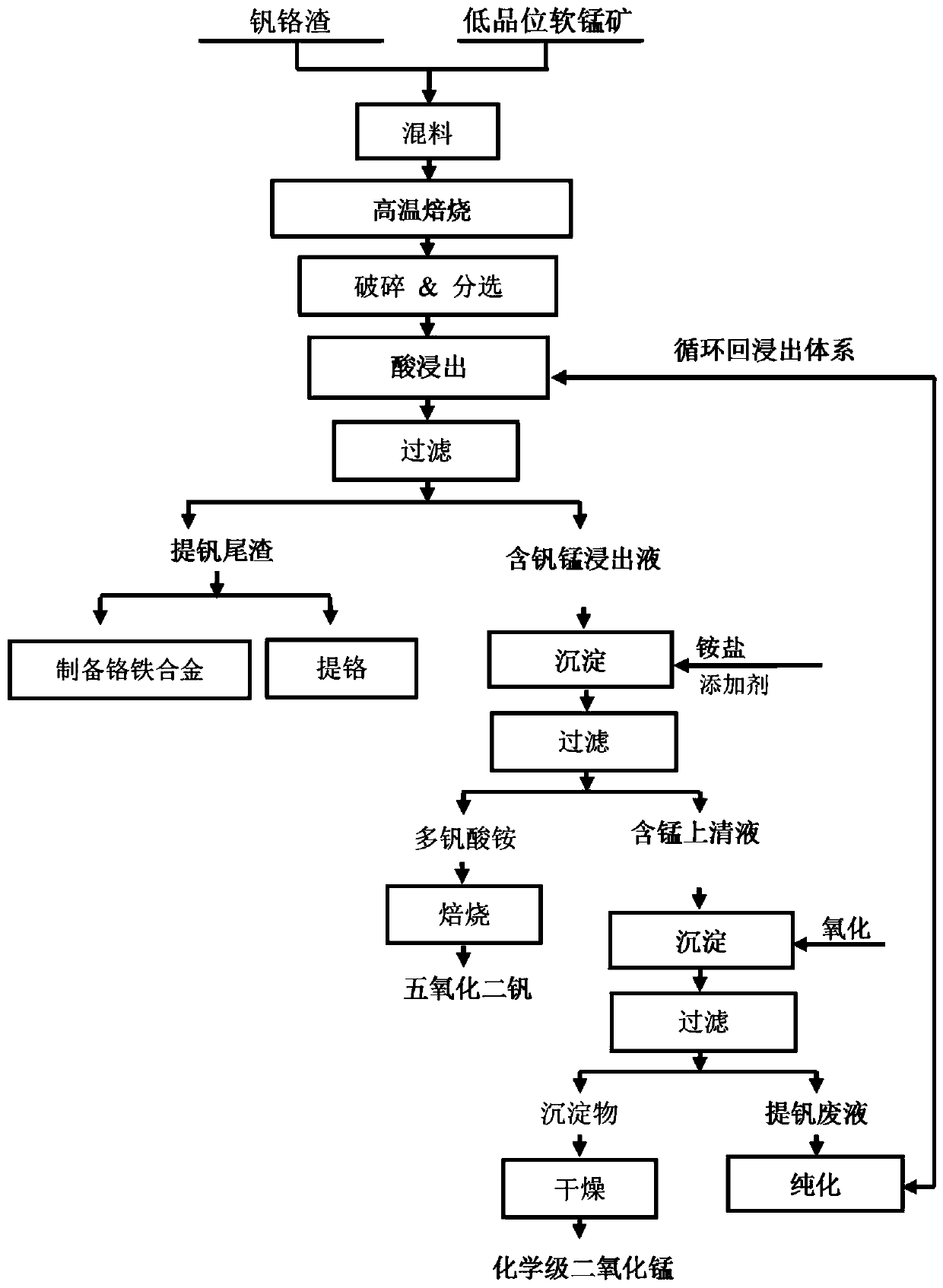

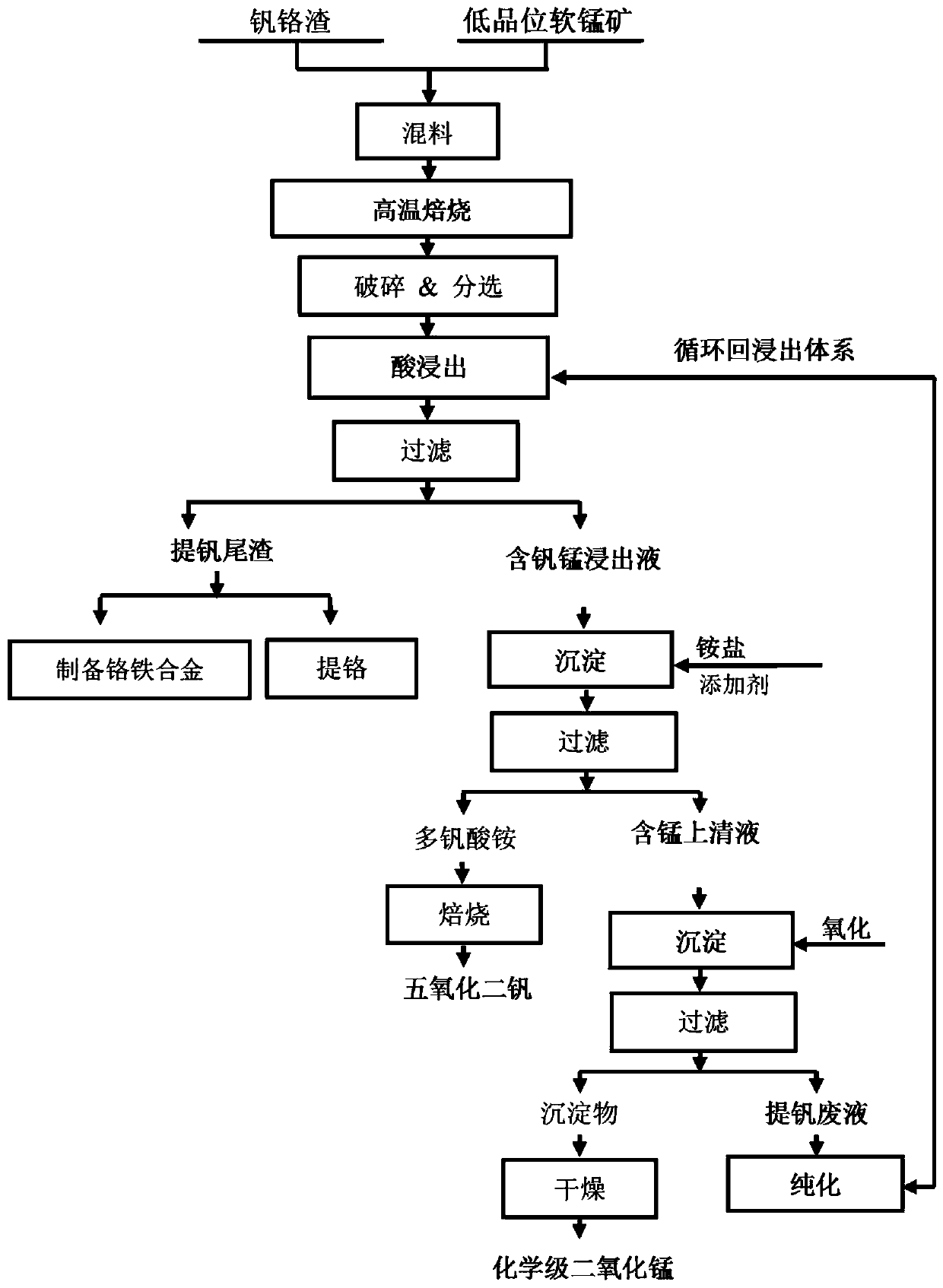

[0034] A method for preparing vanadium pentoxide and chemical grade manganese dioxide by using vanadium chromium slag and low-grade pyrolusite, the process flow is as follows figure 1 shown, including the following steps:

[0035] (1) Take vanadium chromium slag (source is Panzhihua, Sichuan) and sieve after grinding to take 200-250 mesh particle size as raw material, wherein the vanadium content is calculated according to V 2 o 5 Calculated as 14.42%, chromium content by Cr 2 o 3 It is calculated as 9.45%, and the manganese content in low-grade pyrolusite (sourced from Kunming, Yunnan) is 30%. The two raw materials are in molar ratio, and the vanadium in the vanadium-chromium slag is V 2 o3 MnO in low-grade pyrolusite 2 The calculated molar ratio is 1:2 for mixing, and then roasting at 850°C for 120 minutes for manganization roasting, the heating rate is 2°C / min, and the crushed particle size of the roasted material is 250-300 mesh; the particle size of vanadium-chromium...

Embodiment 2

[0043] A method for preparing vanadium pentoxide and chemical grade manganese dioxide by using vanadium chromium slag preparation and low-grade pyrolusite, comprising the following steps:

[0044] (1) to press V 2 o 5 It is calculated as 13.35%, and the chromium content is calculated as Cr 2 o 3 The vanadium chromium slag (the source is Chengde, Hebei Province) of 8.77% is ground and sieved, and the particle size is 250-300 mesh, and the low-grade pyrolusite (the source is Kunming, Yunnan) with a manganese content of 18% is added for mixing. Roasting at 800°C for 180min for manganization roasting, the heating rate is 10°C / min, vanadium chromium slag, so as to manganize the vanadium in the vanadium slag. Among them, vanadium in vanadium-chromium slag is V 2 o 3 Calculated with manganese in pyrolusite as MnO 2 The calculated molar ratio is 1:1. After roasting, the crushed material has a particle size of 250-300 mesh.

[0045] (2) The leaching process is carried out in a ...

Embodiment 3

[0052] A method for preparing vanadium pentoxide and chemical grade manganese dioxide by using vanadium chromium slag preparation and low-grade pyrolusite, comprising the following steps:

[0053] (1) Press V 2 o 5 It is calculated as 15.48%, and the chromium content is calculated as Cr 2 o 3 Calculated as 6.55%, after grinding and sieving, take a particle size of 200-300 mesh and add low-grade pyrolusite (sourced from Xiangtan, Hunan) with a manganese content of 25% for mixing. The vanadium-chromium slag is mixed with V 2 o 3 MnO 2 The molar ratio is 1:3; after that, it is roasted at 900°C for 180 minutes for manganization roasting, and the heating rate is 5°C / min. Among them, the crushed particle size of the roasted material is 200-300 mesh;

[0054] (2) The leaching process is carried out in a heating mantle. The added water and the roasted material are based on a liquid-solid ratio of 20 mL / g. Deionized water is added to the leaching vessel, and the roasted material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com