Cobalt-nickel alloy-porous carbon composite wave-absorbing material with MOF structure and preparation method thereof

A composite wave absorbing material and cobalt-nickel alloy technology, applied in the field of wave absorbing materials, can solve problems such as difficulty in realizing large-scale industrial production, and achieve the effects of good microwave absorption performance, high microwave absorption strength and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation method of the cobalt-nickel alloy-porous carbon composite wave-absorbing material of the present invention specifically comprises the following steps:

[0032] Step 1, weigh 263mg cobalt nitrate and 610mg nickel nitrate and dissolve in 60mL N,N-dimethylformamide, stir until cobalt nitrate and nickel nitrate are completely dissolved; then measure 3mmol trimellitic acid and 3mmol 4'4 - Add bipyridine to the above mixed solution, continue to stir for 30 minutes, transfer the above mixed solution to a high-pressure reactor, place it in a blast drying oven and heat it to 120°C, and keep it warm for 4 hours; after naturally cooling to room temperature, the obtained precipitate is centrifuged Separation, washing and drying to obtain a precursor in the MOF structure;

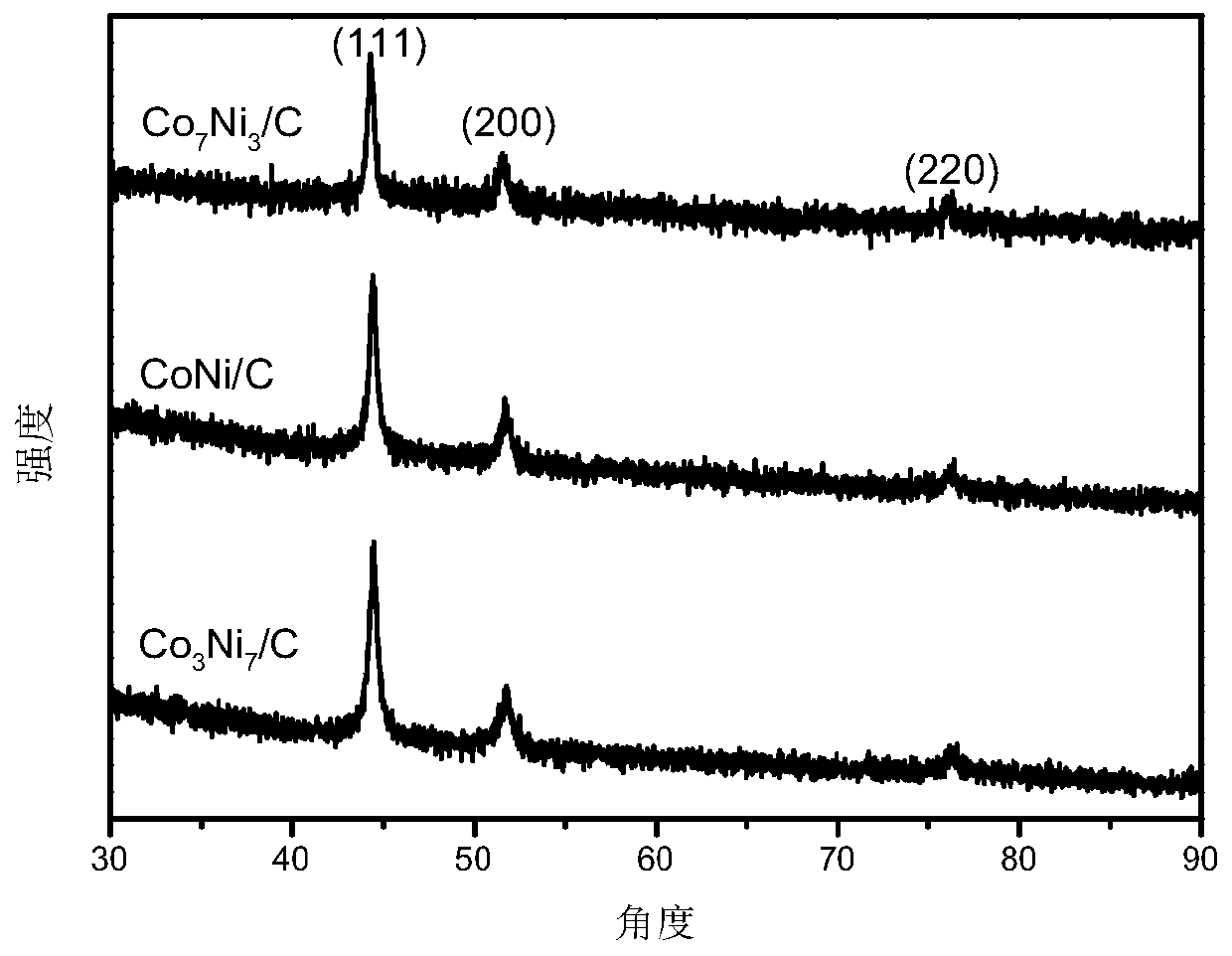

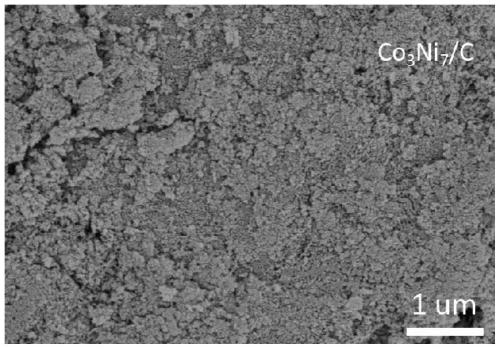

[0033] Step 2, put the precursor obtained in step 1 into a tube furnace under a nitrogen atmosphere and calcinate at 800°C for 2h with a heating rate of 2°C / min; after calcining, cool naturally to...

Embodiment 2

[0035] The preparation method of the cobalt-nickel alloy-porous carbon composite wave-absorbing material of the present invention specifically comprises the following steps:

[0036] Step 1, weigh 438mg cobalt nitrate and 316.5mg nickel nitrate and dissolve in 60mL N, N-dimethylformamide, stir until cobalt nitrate and nickel nitrate are completely dissolved; then measure 3mmol trimellitic acid and 3mmol 4' Add 4-bipyridine to the above mixed solution, continue to stir for 30 minutes, transfer the above mixed solution to a high-pressure reactor, place it in a blast drying oven and heat it to 120°C, and keep it warm for 4 hours; after naturally cooling to room temperature, remove the obtained precipitate Centrifuge and wash and dry to obtain a precursor in the form of MOF;

[0037] Step 2, put the precursor obtained in step 1 into a tube furnace and calcinate at 800°C for 2h under a nitrogen atmosphere, with a heating rate of 2°C / min; after calcining, naturally cool to obtain th...

Embodiment 3

[0039] The preparation method of the cobalt-nickel alloy-porous carbon composite wave-absorbing material of the present invention specifically comprises the following steps:

[0040] Step 1, weigh 613mg cobalt nitrate and 261mg nickel nitrate and dissolve in 60mL N,N-dimethylformamide, stir until cobalt nitrate and nickel nitrate are completely dissolved; then measure 3mmol trimesic acid and 3mmol 4'4 - Add bipyridine to the above mixed solution, continue to stir for 30 minutes, transfer the above mixed solution to a high-pressure reactor, place it in a blast drying oven and heat it to 120°C, and keep it warm for 4 hours; after naturally cooling to room temperature, the obtained precipitate is centrifuged Separation, washing and drying to obtain a precursor in the MOF structure;

[0041] Step 2, put the precursor obtained in step 1 into a tube furnace under a nitrogen atmosphere and calcinate at 800°C for 2h with a heating rate of 2°C / min; after calcining, cool naturally to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

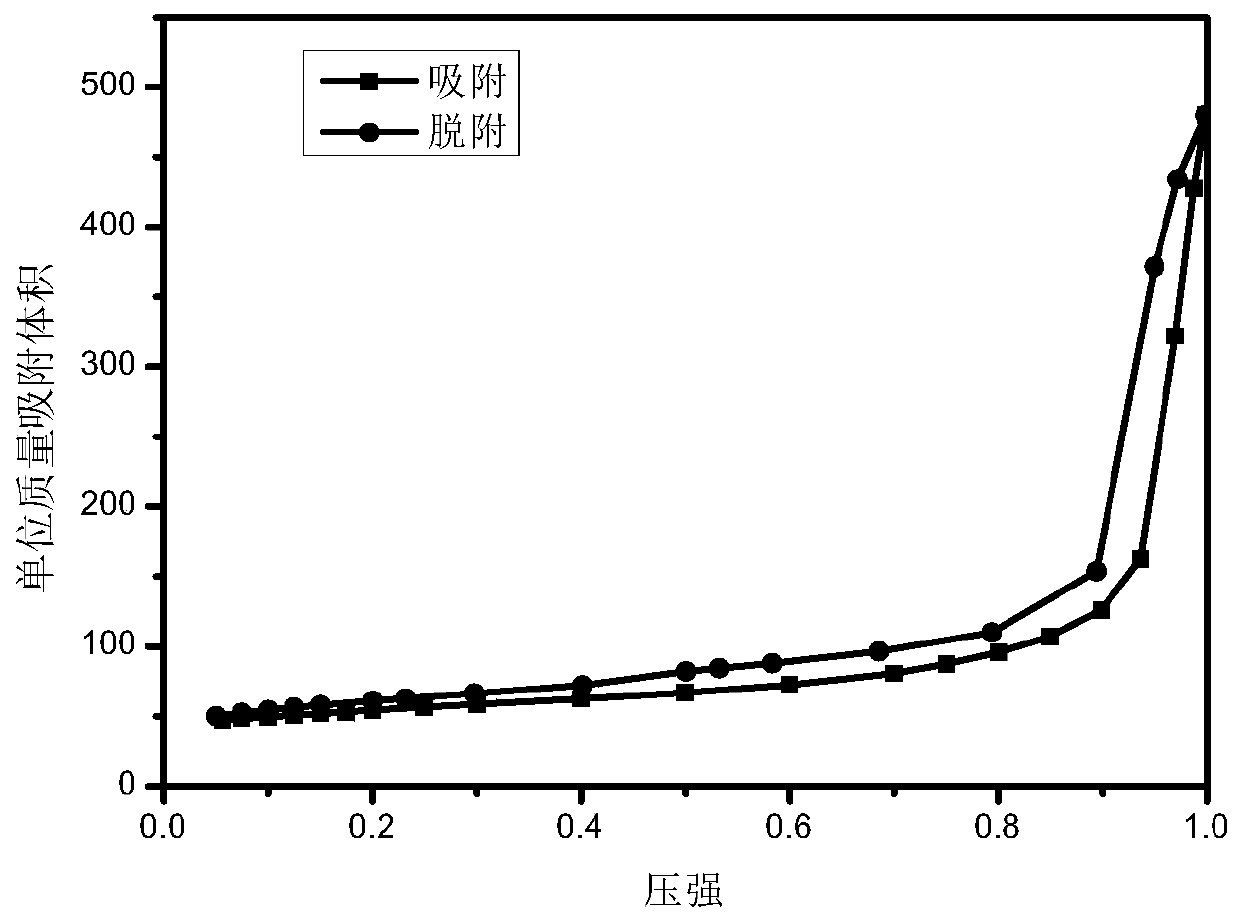

| Specific area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Return loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com