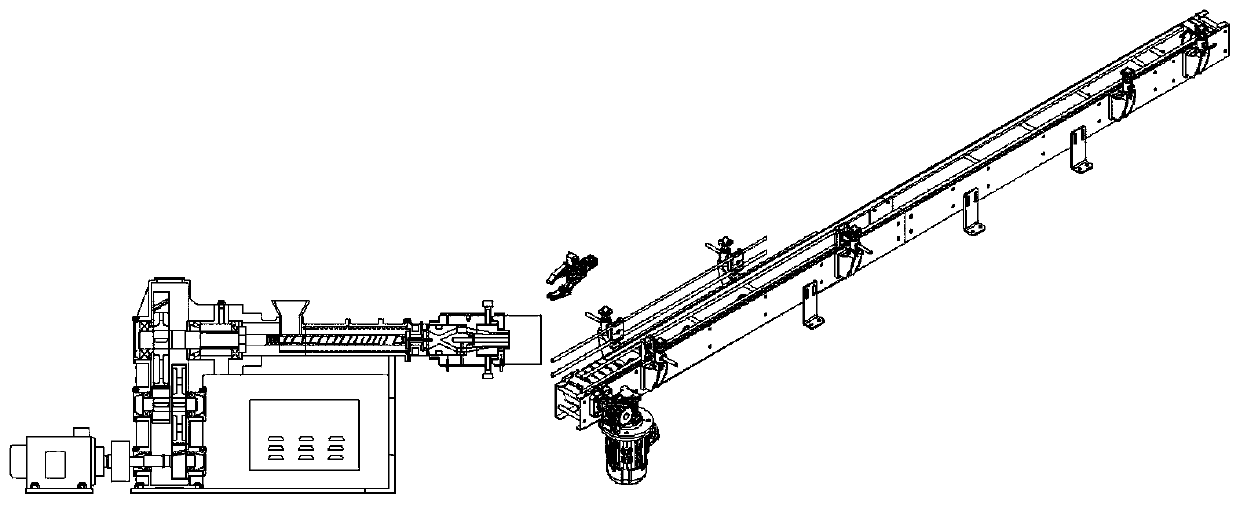

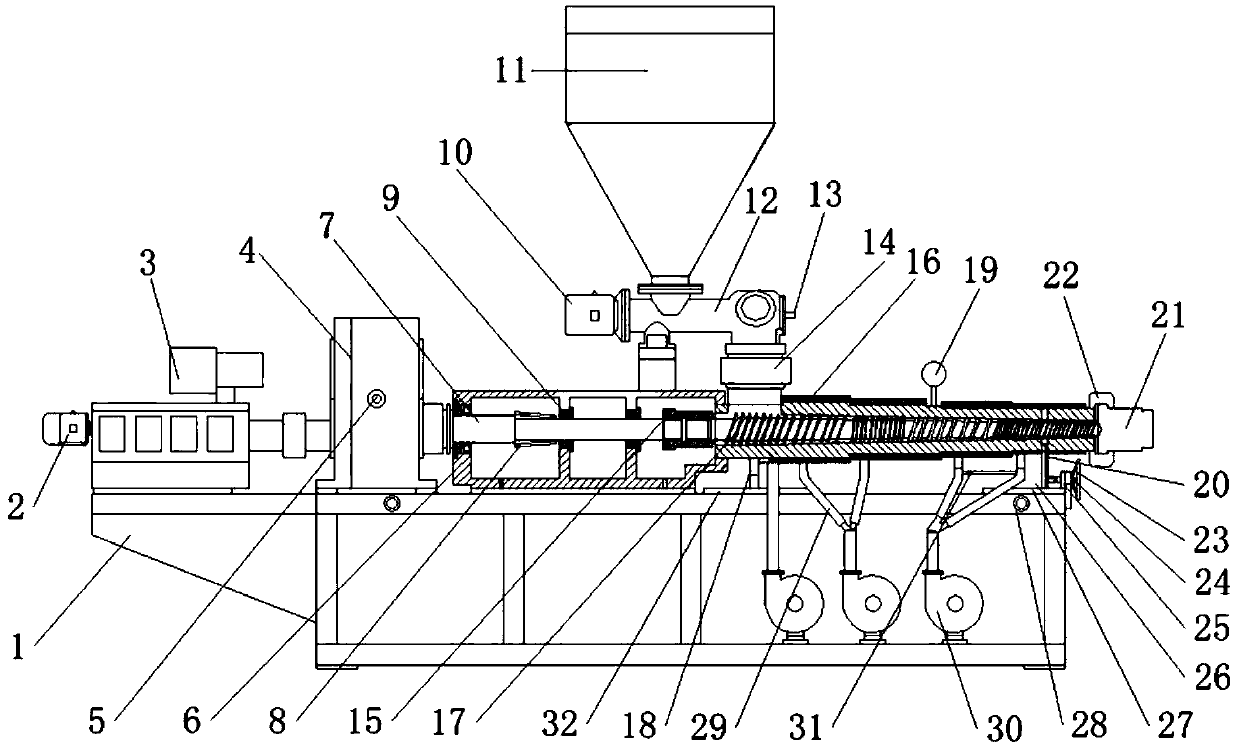

Plastic master batch, conical double screw extruding machine, and injection moulding production processing process line

A conical twin-screw and extruder technology, applied in the field of injection molding machines, can solve the problems of inconvenient assembly and disassembly, high cost input, large body size, etc., and achieves reduction of manpower, material resources, time cost, improvement of mechanical strength and toughness, and simple preparation steps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Prepare gas-barrier biodegradable plastic masterbatches according to the following steps:

[0063] Step 1. Bamboo fiber modification: Take the bamboo fiber powder passed through a 100-mesh sieve and add it to the Pingpinga O-20 aqueous solution with a mass fraction of 0.1%, then add a 1% sodium hydroxide aqueous solution, and then heat it at 70°C Ultrasonic treatment (frequency 20KHz) for 50 minutes, placed in a drying oven at 50°C and dried until the water content is less than 2% to obtain modified bamboo fiber, bamboo fiber powder: Pingpingjia O aqueous solution: sodium hydroxide aqueous solution mass ratio It is 1:1:0.01.

[0064] Step 2: Add 4-6 parts of modified bamboo fiber obtained in step 1 to a high-speed mixer, then add 50 parts of polyhydroxyalkanoate PHA, 20 parts of polylactic acid PLA, 2.5 parts of feather powder, and 0.3 part of ring Oxygenated soybean oil, 0.4 part of dioctyl adipate, 0.7 part of glycidyl methacrylate (GMA), 0.8 part of α-alkyl cyanoacr...

Embodiment 2

[0066] Prepare gas-barrier biodegradable plastic masterbatches according to the following steps:

[0067] Step 1. Bamboo fiber modification: Take the bamboo fiber powder passed through a 200-mesh sieve and add it to the Pingpinga O aqueous solution with a mass fraction of 0.15%, then add a 2% sodium hydroxide aqueous solution, and then ultrasonicate at 60°C (Frequency 20KHz) Treat for 60 minutes, place in a drying oven at 60°C and dry until the water content is less than 2% to obtain modified bamboo fiber, bamboo fiber powder: Pingping O aqueous solution: sodium hydroxide aqueous solution mass ratio is 1 :1:0.02.

[0068] Step 2: Add 4-6 parts of modified bamboo fiber obtained in step 1 into a high-speed mixer, and then add 55 parts of polyhydroxyalkanoate PHA, 20 parts of polylactic acid PLA, 2 parts of feather powder, and 0.5 part of ring Oxygenated soybean oil, 0.2 part of dioctyl adipate, 0.5 part of glycidyl methacrylate (GMA), 0.6 part of α-alkyl cyanoacrylate, 1.0 part...

Embodiment 3

[0070] Prepare gas-barrier biodegradable plastic masterbatches according to the following steps:

[0071] Step 1. Bamboo fiber modification: Take the bamboo fiber powder passed through a 200-mesh sieve and add it to 0.1% Pingpinga O aqueous solution, then add 2% sodium hydroxide aqueous solution, and then ultrasonicate at 70°C (Frequency 20KHz) Treat for 80 minutes, place in a drying box and dry at a temperature lower than 60°C until the water content is less than 2% to obtain modified bamboo fiber, bamboo fiber powder: flat plus O aqueous solution: sodium hydroxide aqueous solution mass ratio It is 1:1:0.01.

[0072] Step 2: Add 4-6 parts of modified bamboo fiber obtained in step 1 to a high-speed mixer, and then add 51 parts of polyhydroxyalkanoate PHA, 18 parts of polylactic acid PLA, 3 parts of feather powder, and 0.5 part of ring Oxygenated soybean oil, 0.4 parts of dioctyl adipate, 0.7 parts of glycidyl methacrylate (GMA), 0.7 parts of α-alkyl cyanoacrylate, 1.2 parts o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com