Polyphenylene sulfide without lithium chloride and additives, and preparation method and applications thereof

A technology of polyphenylene sulfide resin and catalyst, which is applied in the field of polyphenylene sulfide and its preparation, can solve the problems of high recovery rate of lithium chloride, cumbersome recovery process, long reaction route, etc., and achieve excellent thermal stability, High yield, good fluidity and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

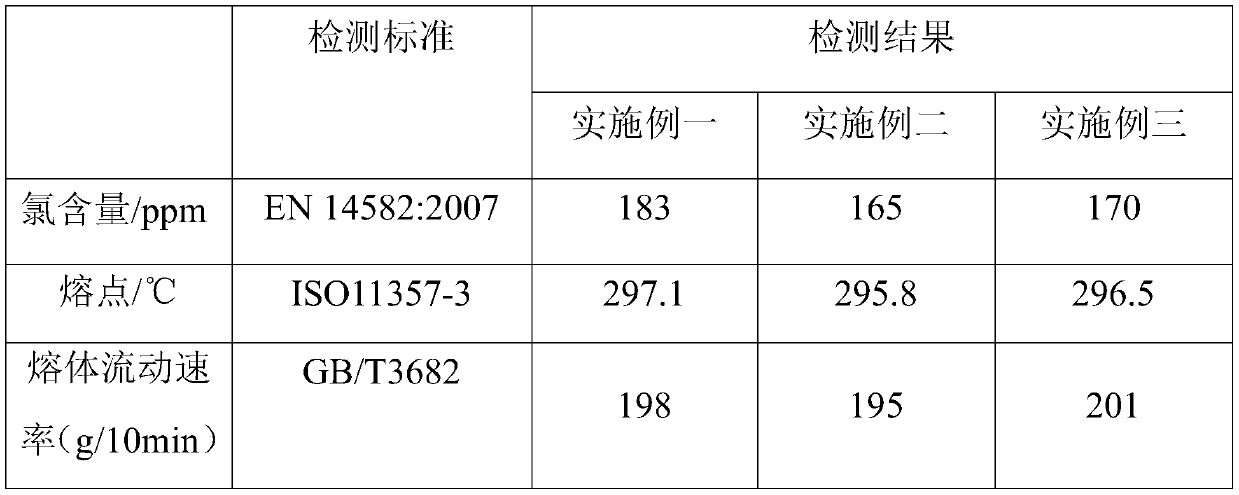

Examples

preparation example Construction

[0025] The invention provides a kind of synthetic method of polyphenylene sulfide resin, comprises the following steps:

[0026] S101: Under an inert gas argon atmosphere, add sulfur powder and catalyst into the reactor, then add N-methylpyrrolidone, heat and stir evenly until a uniform suspension is formed in the reactor. Among them, the catalyst includes butyl myristate, La(NO 3 ) 3 and MCM-41 mesoporous molecular sieve; and butyl myristate, La(NO 3 ) 3 The molar ratio of MCM-41 mesoporous molecular sieve is (0.5~2.5):(0.01~0.05):10; the molar ratio of sulfur powder, catalyst, N-methylpyrrolidone and dichlorobenzene is 1:(0.005~ 0.05): (3~8): (1.05~1.30).

[0027] S102: Add dichlorobenzene to the suspension obtained in S101, raise the temperature to 120-150° C. at a rate of 1-5° C. / min, and stir at constant temperature for 1-3 hours.

[0028] S103: Cool the product obtained in S102 to room temperature, then separate the solid from the liquid and collect the solid phase....

Embodiment 1

[0034] The present embodiment provides a kind of synthetic method of polyphenylene sulfide resin, comprises the following steps:

[0035] S101: First, introduce argon gas to replace the gas in the reaction system, and keep the gas flow rate at 90mL / min, add sulfur powder and catalyst into the reaction kettle, then add N-methylpyrrolidone, heat and stir until a uniform suspension. Among them, the molar ratio of sulfur powder, catalyst, N-methylpyrrolidone and dichlorobenzene is 1:0.05:3:1.30 in sequence.

[0036] The catalyst includes butyl myristate, La(NO 3 ) 3 and MCM-41 mesoporous molecular sieve; its preparation method comprises the following steps: S201: butyl myristate, La(NO 3 ) 3 Mix with the carrier and stir until clear, then dry; S202: Place the product obtained in S201 in a nitrogen flow with a gas flow rate of 100mL / min, heat it to 220°C at a heating rate of 1°C / min, then keep the temperature for 5h, and then The temperature was lowered to 50° C. at a cooling ...

Embodiment 2

[0041] The present embodiment provides a kind of synthetic method of polyphenylene sulfide resin, comprises the following steps:

[0042] S101: First, introduce argon gas to replace the gas in the reaction system, and keep the gas flow rate at 60mL / min, add sulfur powder and catalyst into the reaction kettle, then add N-methylpyrrolidone, heat and stir until a uniform suspension. Among them, the molar ratio of sulfur powder, catalyst, N-methylpyrrolidone and dichlorobenzene is 1:0.005:8:1.02 in sequence.

[0043] The catalyst includes butyl myristate, La(NO 3 ) 3 and MCM-41 mesoporous molecular sieve; its preparation method comprises the following steps: S201: butyl myristate, La(NO 3 ) 3 Mix with the carrier and stir until clear, then dry; S202: Place the product obtained in S201 in a nitrogen stream with a gas flow rate of 20mL / min, heat it to 280°C at a heating rate of 3°C / min, then keep the temperature for 2h, and then The temperature was lowered to 80° C. at a coolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com