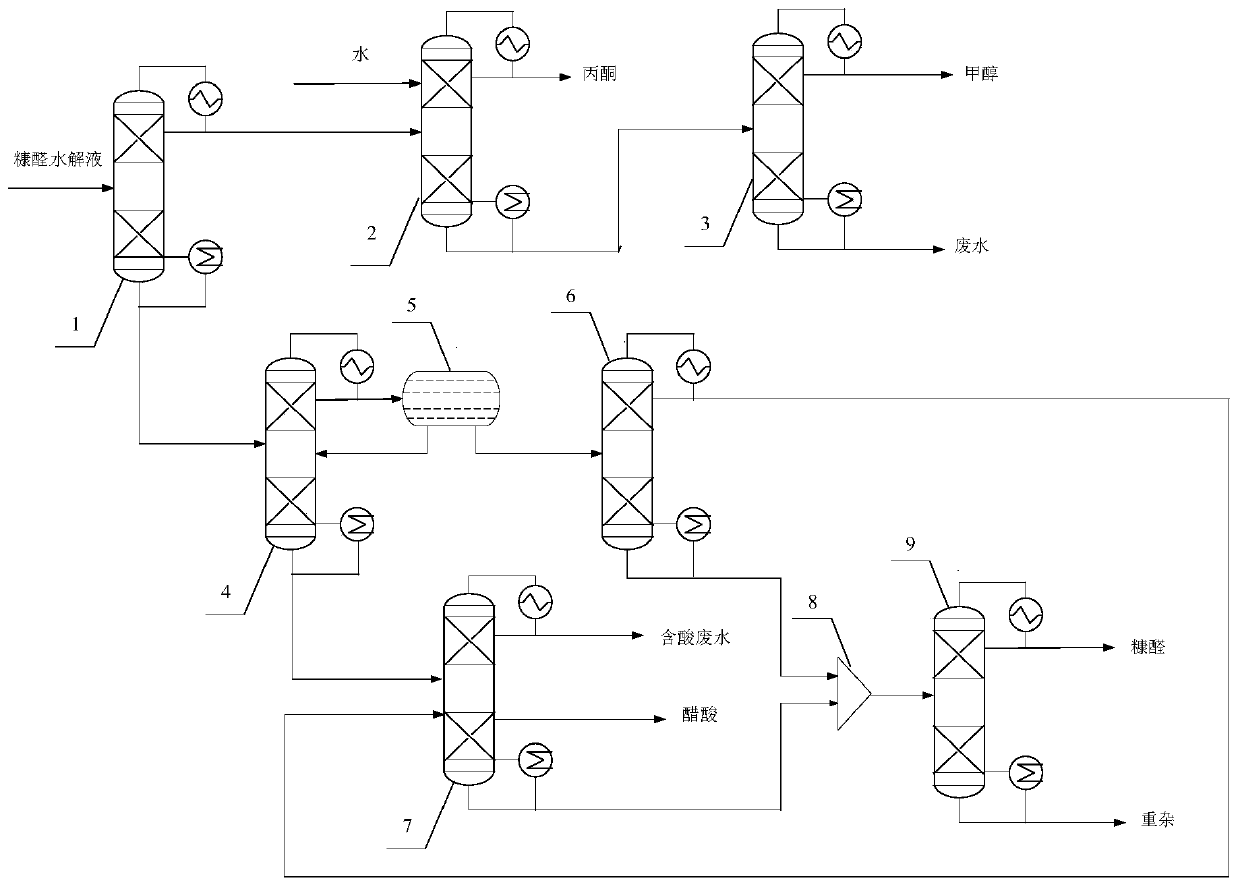

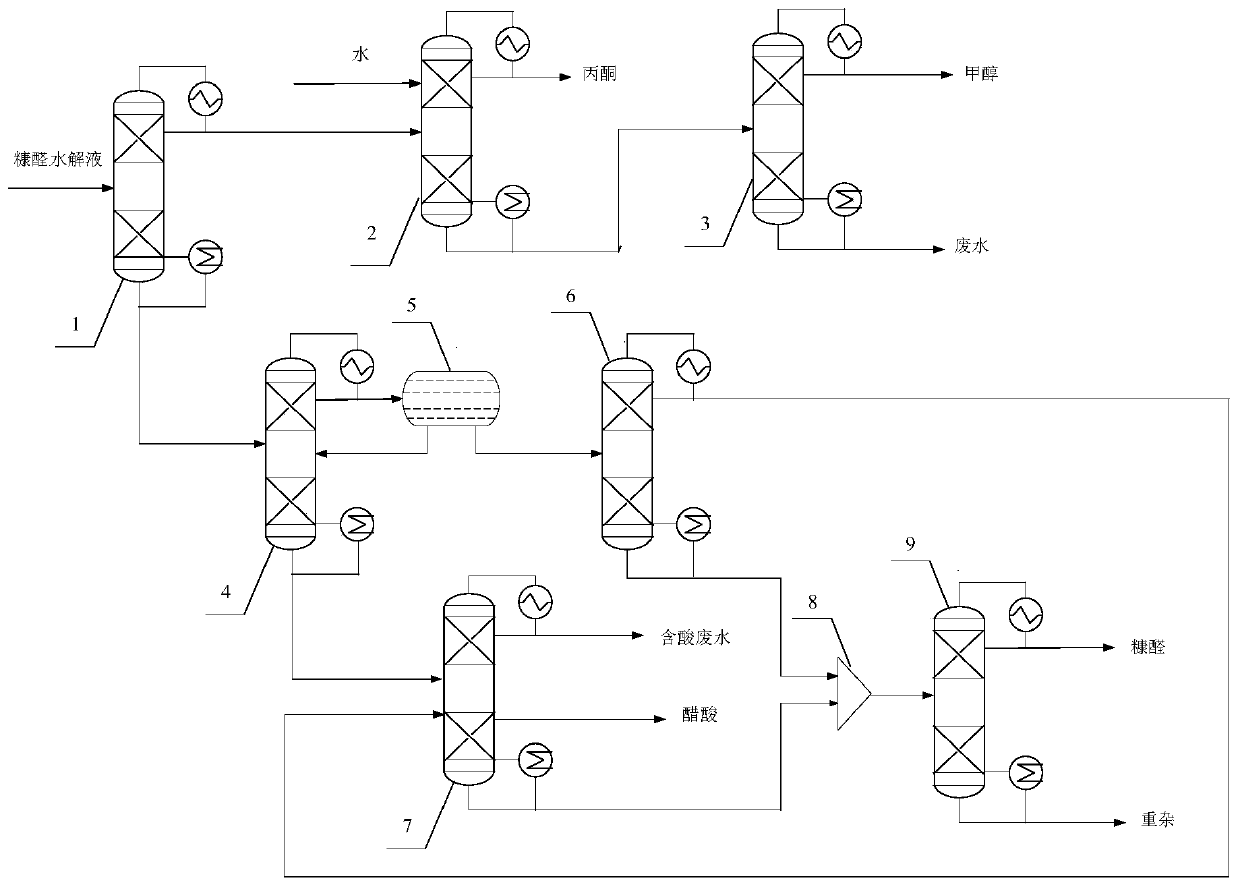

Method for continuously rectifying and refining furfural and accessory low-boiling-point substance

A technology of low boiling matter and furfural, which is applied in the field of continuous distillation and refining, can solve the problems of unreasonable furfural refining process, etc., and achieve the effects of preventing the risk of reaction to form resin, easy handling and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] After heat exchange, the feed temperature is 35°C, the flow rate is 20000kg / hr, and the content of each component is: the mass fraction of furfural is 16.5%, methanol and acetone are 5%, acetic acid is 8%, formic acid is 0.5%, and water is 64%. The rest is the furfural hydrolyzate with heavy impurities mainly 5-methylfurfural, which is pumped into the light removal tower from the upper part of the tower, and acetone and methanol with lower boiling points are extracted from the top of the light removal tower, and the bottom liquid of the tower is a dilute solution of furfural , the light component methanol and acetone in the tower still liquid are almost completely removed, and the methanol content in the tower still is less than or equal to 50ppm. is 13; the light removal tower is operated under normal pressure, the operating pressure at the top of the tower is 100kPa, and the pressure at the bottom of the tower is about 105kPa; at this time, the temperature at the top o...

Embodiment 2

[0035] After heat exchange, the feed temperature is 38°C, the flow rate is 18000kg / hr, and the content of each component is: the mass fraction of furfural is 16.5%, methanol and acetone are 5%, acetic acid is 8%, and formic acid is 0.5%. , water 64%, and the rest is the furfural hydrolyzate of heavy impurities mainly based on 5-methylfurfural. The pump enters the light removal tower from the top of the tower, and acetone and methanol with lower boiling points are extracted from the top of the light removal tower. It is a dilute solution of furfural, and the light components methanol and acetone in the tower kettle liquid are almost completely removed, and the methanol content in the tower kettle is ≤50ppm. 7 plates, the reflux ratio is 8; the light removal tower is operated under normal pressure, the operating pressure at the top of the tower is 102kPa, and the pressure of the tower bottom is about 107kPa; The acetone and methanol light components at the top of the light tower...

Embodiment 3

[0037]After heat exchange, the feed temperature is 35°C, the flow rate is 22000kg / hr, and the content of each component is: the mass fraction of furfural is 16.5%, methanol and acetone are 5%, acetic acid is 8%, and formic acid is 0.5%. , water 64%, and the rest is the furfural hydrolyzate of heavy impurities mainly based on 5-methylfurfural. The pump enters the light removal tower from the top of the tower, and acetone and methanol with lower boiling points are extracted from the top of the light removal tower. It is a dilute solution of furfural, and the light components methanol and acetone in the tower kettle liquid are almost completely removed, and the methanol content in the tower kettle is ≤50ppm. 10 blocks, with a reflux ratio of 8; the light removal tower is operated at normal pressure, the operating pressure at the top of the tower is 105kPa, and the pressure of the tower bottom is about 110kPa; The acetone and methanol light components at the top of the tower are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com