Composite synergist and sleeve grouting material for steel bar connection and preparation method thereof

A composite synergistic and sleeve grouting technology, applied in the field of building materials, can solve the problems of failing to meet the requirements of mechanical properties, difficult to meet the requirements of high flow state, fast setting speed, etc., to achieve excellent pull-out resistance, improve Mechanical properties, anti-erosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

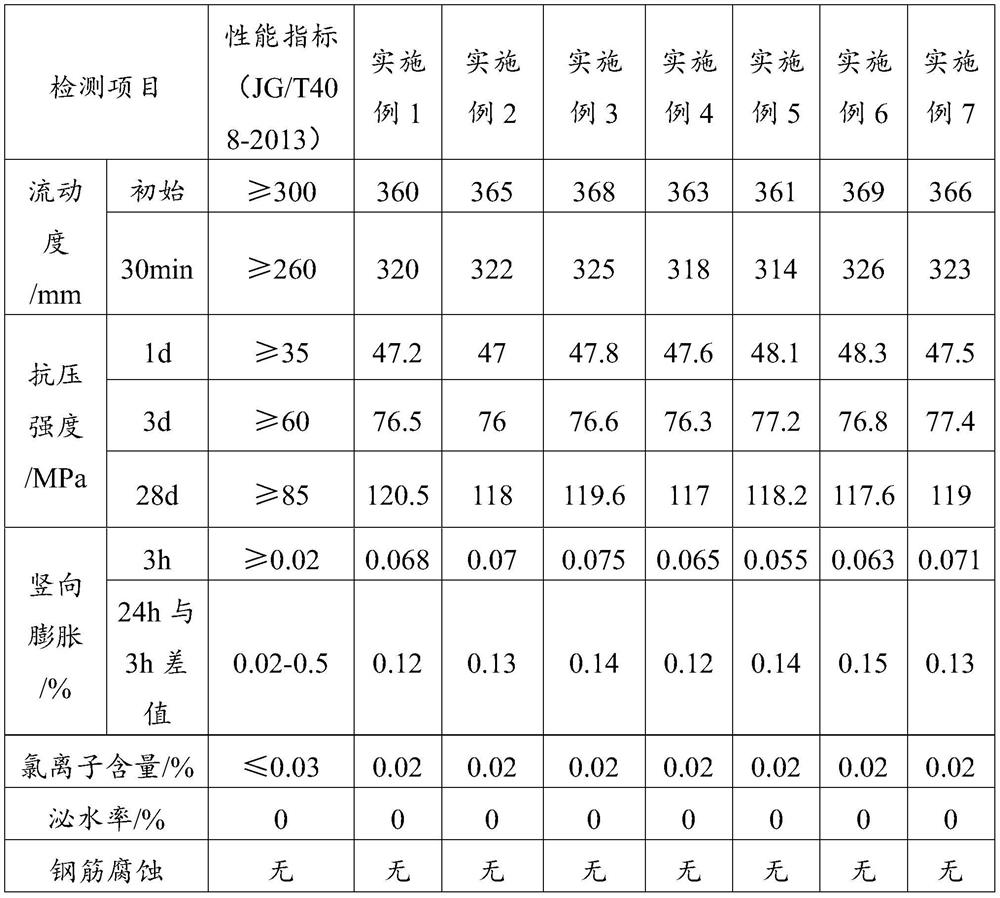

Examples

Embodiment 1

[0030] Embodiment 1: A composite synergist, the composite synergist is composed of the following components: 31% modified ultrafine steel slag powder, 53% ultrafine slag powder, 6% fly ash, 3.5% desulfurized gypsum, composite expansion 2% additive, 0.1% graphene oxide, 2.4% rust inhibitor, 1% stabilizer and 1% composite fiber.

[0031] The composite synergist is mixed with the grouting reference material to prepare the sleeve grouting material for steel bar connection. The composition of the components mixed in weight percentage is as follows: 14% composite synergist, 36% cement, 49.6% aggregate, defoaming Agent 0.02%, polycarboxylate superplasticizer 0.3% and composite early strength agent 0.08%.

Embodiment 2

[0032] Embodiment 2: A composite synergist, the composite synergist consists of the following components: 32% modified ultrafine steel slag powder, 52% ultrafine slag powder, 7% fly ash, 3.5% desulfurized gypsum, composite expansion 2% additive, 0.1% graphene oxide, 1.4% rust inhibitor, 1% stabilizer and 1% composite fiber.

[0033] The composite synergist is mixed with the grouting reference material to prepare the sleeve grouting material for steel bar connection. The composition of the components mixed in weight percentage is as follows: 12% composite synergist, 37.42% cement, 50% aggregate, defoaming 0.06% agent, 0.4% polycarboxylate superplasticizer and 0.12% composite early strength agent.

Embodiment 3

[0034] Embodiment 3: A composite synergist, the composite synergist consists of the following components: 33% modified ultrafine steel slag powder, 53.8% ultrafine slag powder, 5% fly ash, 3% desulfurized gypsum, composite expansion agent 1.8%, graphene oxide 0.05%, rust inhibitor 1.5%, stabilizer 0.9% and composite fiber 0.95%.

[0035] The composite synergist is mixed with the grouting reference material to prepare the sleeve grouting material for steel bar connection. The composition of the components mixed in weight percentage is as follows: 12.5% of the composite synergist, 37.5% of the cement, 49.57% of the aggregate, and 0.04% agent, 0.3% polycarboxylate superplasticizer and 0.09% composite early strength agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com