ZBYA fluoride glass and preparation method thereof

A fluoride and glass technology, applied in the field of ZBYA fluoride glass and its preparation, can solve the problems of low maximum phonon energy, low pumping efficiency and weak mid-infrared fluorescence intensity of matrix glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

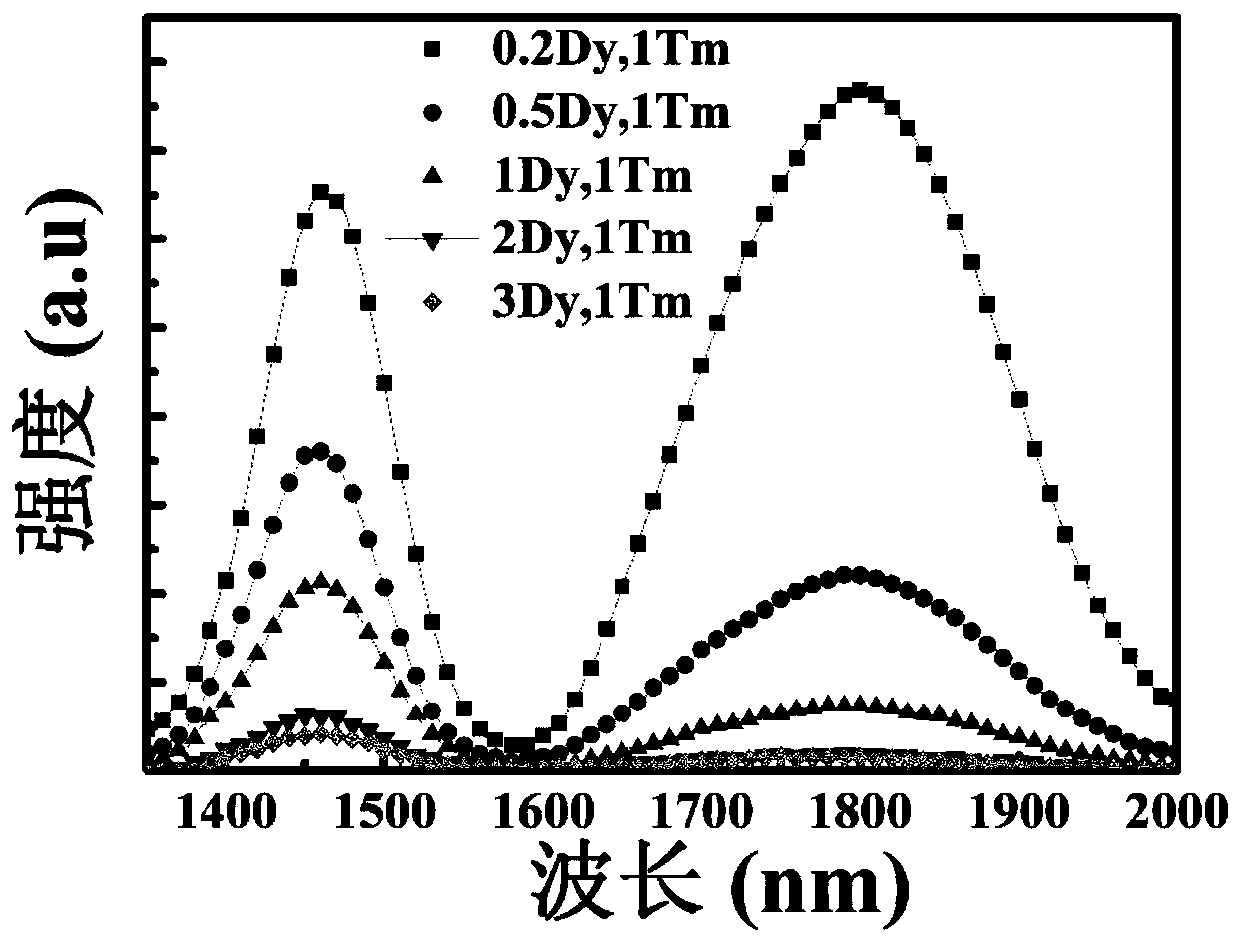

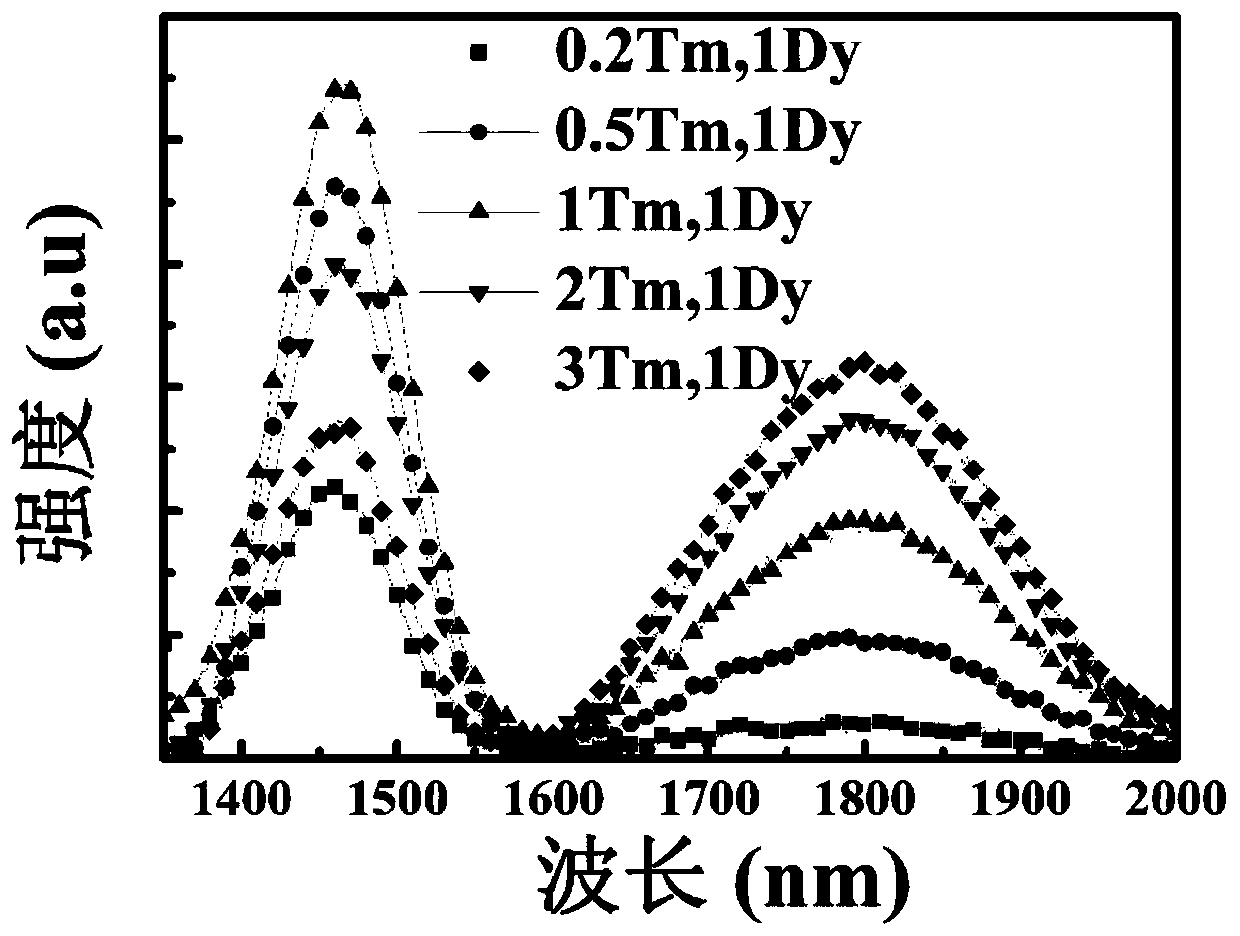

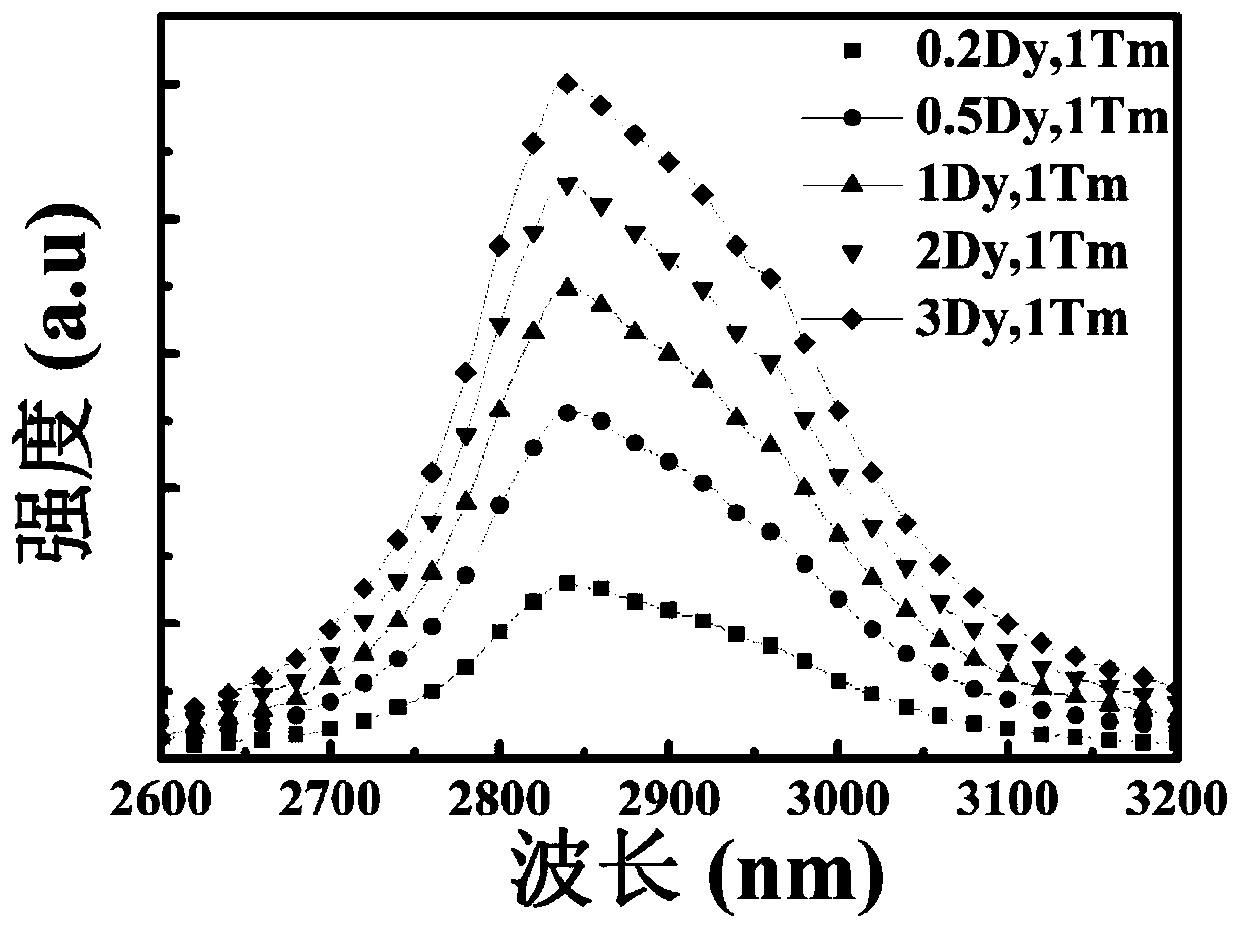

[0052] Use the above steps to make glass samples according to the ratio of raw materials, and the resulting Dy 3+ and Tm 3+ The co-doped ZBYA fluoride glass sample can achieve 1.47μm, 1.8μm near-infrared fluorescence emission and 2.9μm, 4.3μm mid-infrared fluorescence emission under the excitation of 808nm pump source. figure 1 Change Dy in Example 3+ Near-infrared luminescence spectrum of ZBYA glass with doping concentration, figure 2 Change Tm for example 3+ Near-infrared emission spectrum of ZBYA glass with doping concentration. It can be seen that when doped with Tm 3+ When the mole percentage is 1, doping Dy 3+ The molar percentage of 0.2 can achieve the most efficient near-infrared fluorescence output; when doped with Dy 3+ When the molar percentage is 1, the doped Tm 3+ The molar percentage of is also 1 to achieve the most efficient near-infrared fluorescence output. image 3 Change Dy in Example 3+ Doping concentration ZBYA glass 2.9μm luminescence spectrum, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com