Special extinction powder for water-based coating and preparation method of special extinction powder

A technology of water-based paint and matting powder, applied in chemical instruments and methods, coatings, inorganic chemistry, etc., can solve the problems of reducing water resistance of water-based paint film, reducing paint film resistance, low crosslinking density of paint film, etc., to achieve Reduce the generation of microcracks, increase the crosslinking density, and have good anti-settling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

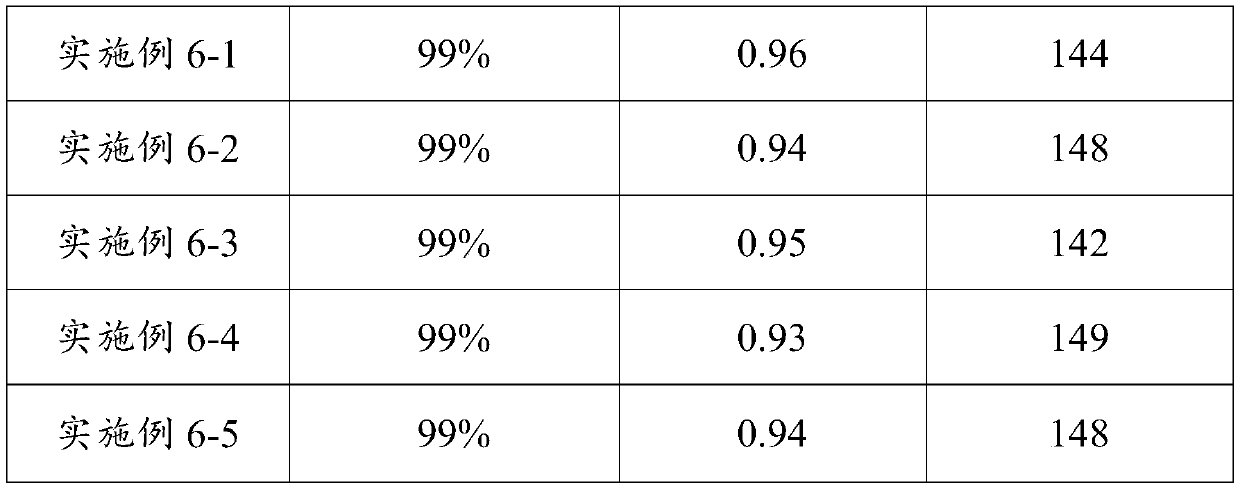

Examples

Embodiment 1

[0034] The present embodiment provides a kind of preparation method of special matting powder for water-based paint, which comprises the following steps:

[0035] S1) Add 700 parts of water and 1 part of precipitated silica powder with a particle size of 3 μm to the reactor, and adjust the pH value of the solution to 11 with water glass I; after stirring evenly, add silica at a concentration of 10% water glass II and 50% sulfuric acid aqueous solution, the co-current time is 60min, and the co-current temperature is 30°C; during the co-current period, when gel appears, stop the co-current and stop adding the remaining water glass II and sulfuric acid Aqueous solution, turn off the stirring and let it stand for 60 minutes; after stirring again for 30 minutes, add the remaining water glass II and sulfuric acid aqueous solution to the reaction kettle, and continue to flow in parallel; the water glass II added in the reaction kettle is 1000 parts, and the sulfuric acid aqueous solut...

Embodiment 2

[0043]The present embodiment provides a kind of preparation method of special matting powder for water-based paint, which comprises the following steps:

[0044] S1) Add 500 parts of water and 0.2 parts of fumed silica powder with a particle size of 15 μm into the reaction kettle, adjust the pH value of the solution to 8 with water glass I; after stirring evenly, add the silica concentration to the reaction kettle. 10% water glass II and 25% sulfuric acid aqueous solution, the co-current time is 90min, and the co-current temperature is 90°C; during the co-current period, when gel appears, stop the co-current and stop adding the remaining water glass II and sulfuric acid Aqueous solution, turn off the stirring and let it stand for 30 minutes; after stirring again for 30 minutes, add the remaining water glass II and sulfuric acid aqueous solution to the reaction kettle, and continue to flow in parallel; the water glass II added in the reaction kettle is 1000 parts, and the sulfur...

Embodiment 3

[0052] The present embodiment provides a kind of preparation method of special matting powder for water-based paint, which comprises the following steps:

[0053] S1) Add 300 parts of water and 0.5 parts of gel-process silica powder with a particle size of 5 μm to the reactor, and adjust the pH value of the solution to 9 with water glass I; after stirring evenly, add the concentration of silica to the reactor 8% water glass II and 25% sulfuric acid aqueous solution, the co-current time is 30min, and the co-current temperature is 50°C; during the co-current period, when gel appears, stop the co-current and stop adding the remaining water glass II and Aqueous sulfuric acid solution, turn off the stirring and let it stand for 90 minutes; after re-stirring for 30 minutes, add the remaining water glass II and aqueous sulfuric acid solution to the reaction kettle, and continue to flow in parallel; the water glass II added in the reaction kettle is 1250 parts, and the aqueous sulfuric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com