Hydrogenation catalyst, preparation method thereof, and hydrotreating method of aromatic hydrocarbon-containing oil

A hydrogenation catalyst and catalyst technology, applied in molecular sieve catalysts, chemical instruments and methods, hydrogenation and refining of aromatics, etc., can solve the problems of low saturation of aromatics, poor thermal and hydrothermal stability, and low proportion of secondary pores, etc. problem, to achieve high aromatic saturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] In the present invention, the mother liquor after crystallization can be prepared according to conventional methods in the art, for example, when the ten-membered ring silica-alumina molecular sieve is ZSM-22 molecular sieve, the preparation method of the mother liquor after crystallization can refer to the literature O.Muraza et al., Microporous and Mesoporous Materials 206 (2015) 136-143; when the ten-membered ring silicon aluminum molecular sieve is ZSM-48 molecular sieve, the preparation method of the mother liquor after crystallization can refer to the literature P.Me'riaudeau et al / Journal of Catalysis, 1999(185), 435-444, or refer to US Patent Application US5961951. In one embodiment, the preparation process of the crystallization mother liquor of the ten-membered ring silica-alumina molecular sieve includes: preparing a silicon-containing solution, an aluminum-containing solution, and an alkaline liquid, mixing the above-mentioned liquids to form gels, and then ...

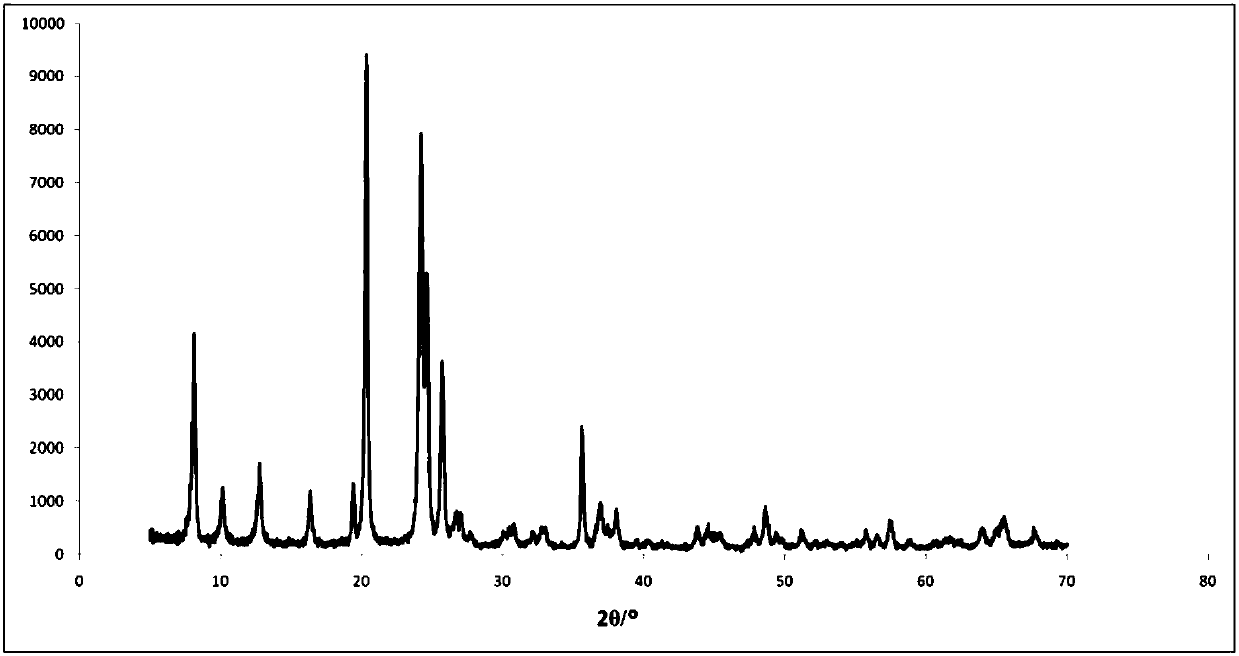

preparation example 1

[0077] (1) Preparation of mother liquor after crystallization

[0078] Get 45 grams of white carbon black, 1.25 grams of analytically pure Al 2 (SO 4 ) 3 18H 2 O, 1.88 grams of analytically pure NaOH and 39.3 grams of hexamethylenediamine are ready for use. Mix hexamethylenediamine with silica and 200 g of deionized water, NaOH and Al 2 (SO 4 ) 3 18H 2 O and 272 grams of deionized water were mixed, and then the two solutions were mixed, stirred for 1 hour, then transferred to a reaction kettle, and crystallized at 160° C. for 72 hours.

[0079] (2) Preparation of filter cake

[0080] Filter the mother liquor after crystallization prepared in the operation (1), and continue suction filtration for 5 minutes when there is no filtrate on the filter cake, and obtain the filter cake F-1, which has a dry basis content of 11.2 %, the silica / alumina molar ratio is 30.2.

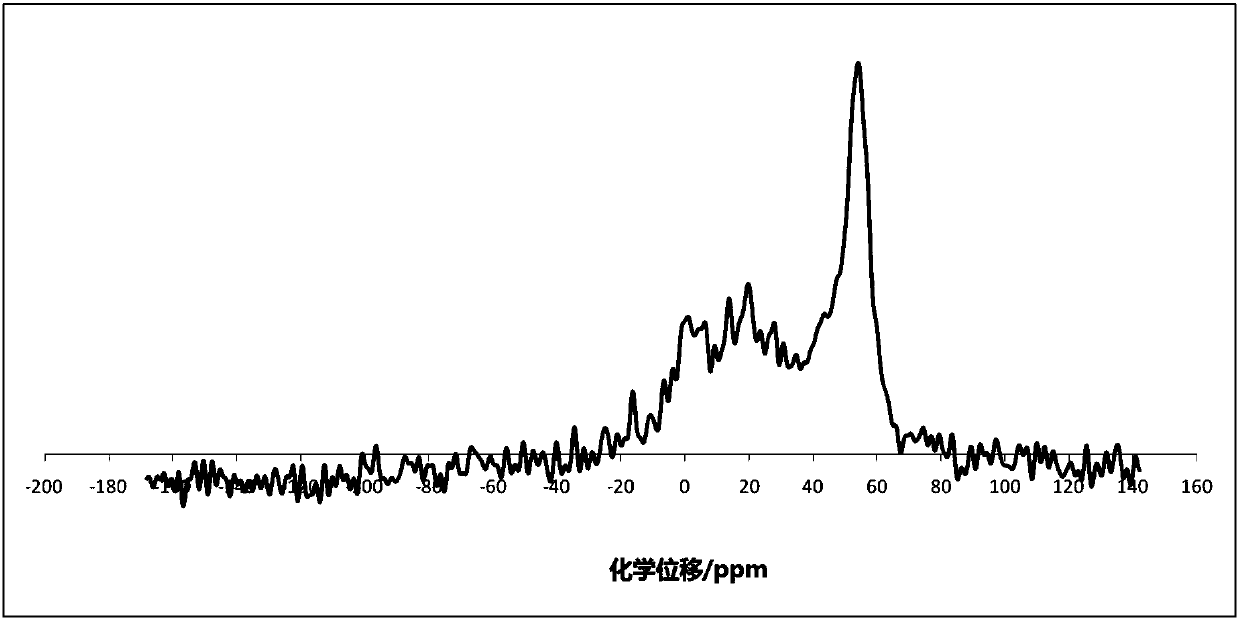

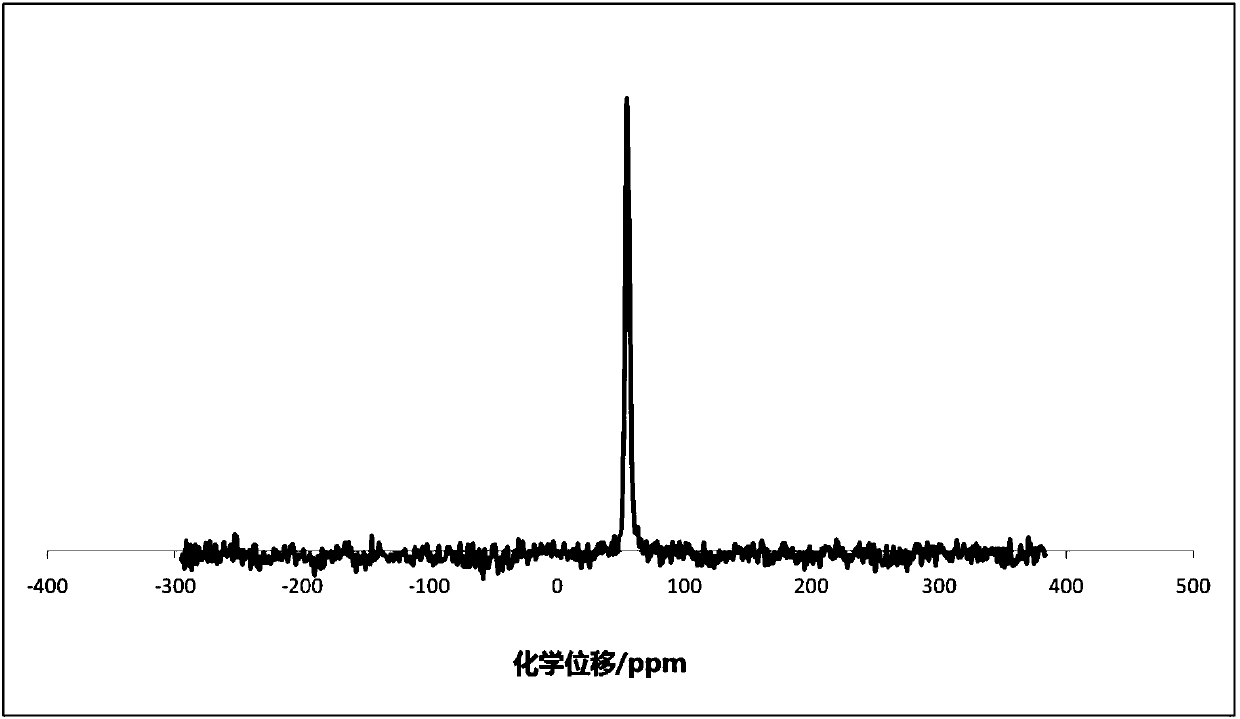

[0081] (3) Preparation of molecular sieve precursor

[0082] The filter cake F-1 was raised from room te...

preparation example 2

[0089] The ZSM-48 molecular sieve was prepared according to the method of Preparation Example 1, except that in step (3), the filter cake F-1 was raised from room temperature to 350°C at a heating rate of 5°C / min, and kept at a constant temperature for 14 hours. During the heating process, the roasting furnace is a closed roasting furnace to obtain the molecular sieve precursor C-2. The finished product H-2 of ZSM-48 molecular sieve was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com