Platinum and palladium containing bimetallic catalyst, preparation method therefor, application of platinum and palladium containing bimetallic catalyst and aromatic-hydrocarbon saturation method

A bimetallic catalyst and catalyst technology are applied in the field of aromatic hydrocarbon saturation methods to achieve the effects of improved relative activity, high aromatic hydrocarbon saturation activity and anti-sulfur performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

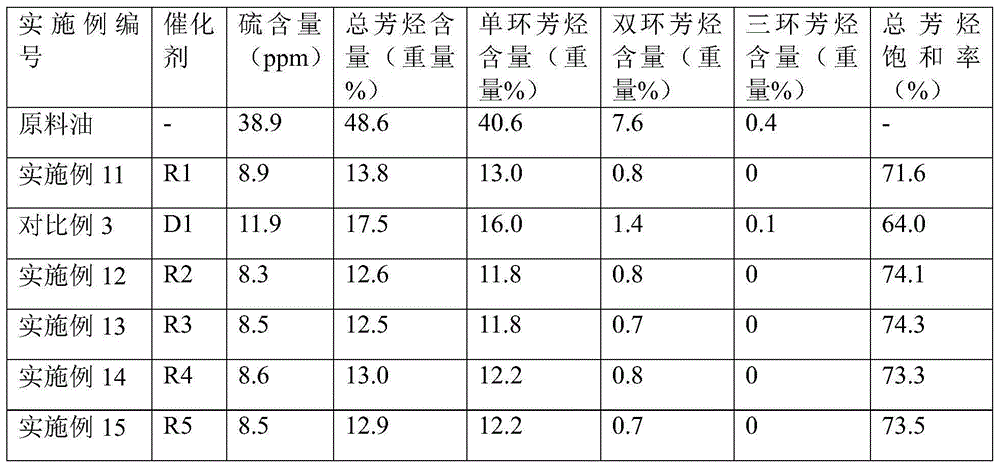

Examples

preparation example Construction

[0018] The invention provides a kind of preparation method of the bimetallic catalyst containing platinum and palladium, and this preparation method comprises the following steps:

[0019] 1) impregnating the carrier with a solution containing a palladium compound, then drying, roasting and reducing the impregnated carrier in sequence to obtain a palladium-containing single metal catalyst precursor;

[0020] 2) impregnating the palladium-containing monometallic catalyst precursor obtained in step 1) with a solution containing a platinum compound in a reducing atmosphere, and then drying to remove the solvent.

[0021] According to the present invention, the palladium compound in the solution containing the palladium compound can be various soluble compounds of palladium, preferably a water-soluble salt of palladium or chloropalladium acid, more preferably Pd(NH 3 ) 4 (NO 3 ) 2 , Pd(NH 3 ) 4 Cl 2 、H 2 PdCl 4 one or more of.

[0022] The concentration of the palladium c...

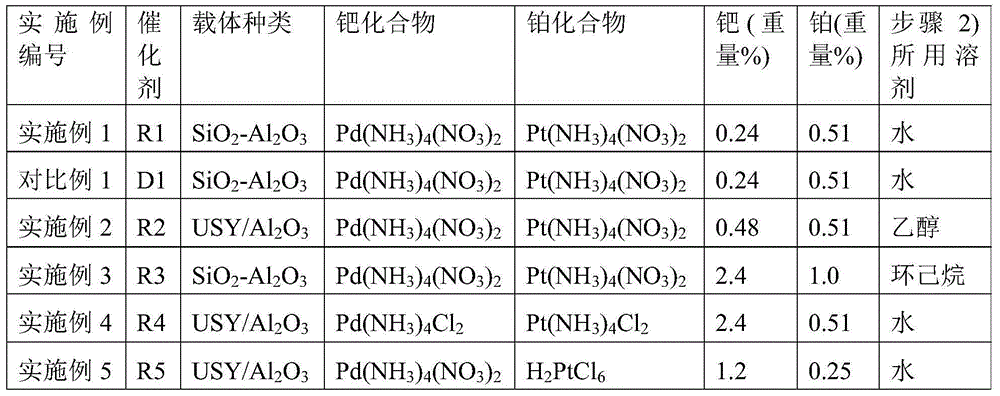

Embodiment 1

[0046] This example is used to illustrate the catalyst provided by the present invention and its preparation method.

[0047] Weigh 0.476 g of Pd(NH 3 ) 4 (NO 3 ) 2 Dissolve in deionized water to prepare an impregnation solution with a Pd atomic concentration of 2.95 g / L, and impregnate to 72 g of SiO in equal volume 2 -Al 2 o 3 The carrier (prepared with reference to Example 2 of CN201110139331.X) was dried at 120°C after standing for 3 hours, calcined at 450°C for 4 hours, hydrogen reduced at 450°C for 4 hours, and the hydrogen pressure was 0.1 MPa. After reduction, it was cooled to room temperature, and 85 milliliters of dissolved 0.736 gram of Pt(NH 3 ) 4 (NO 3 ) 2 The aqueous solution (containing Pt atomic concentration is 4.36 grams per liter), and continues to pass reducing gas bubbling, and hydrogen flow rate is 50 milliliters per minute, until solution is blown dry, and the catalyst obtained is denoted as R1, and its composition is shown in Table 1.

Embodiment 2

[0053] This example is used to illustrate the catalyst provided by the present invention and its preparation method.

[0054] Get 100 grams of USY molecular sieves (produced by Changling Catalyst Factory, sodium oxide content is 0.8% by weight) and add 1000 milliliters of 8.0% by weight ammonium chloride solution, carry out ion exchange for 2 hours under stirring at 90 ° C, filter, and wash with deionized water until Chloride-free, drying at 120° C. for 4 hours to obtain USY molecular sieve A with a sodium oxide content of 0.3% by weight.

[0055] Weigh 60 grams of USY molecular sieve A (dry basis weight) and 120 grams of pseudoboehmite (dry basis weight, produced by Changling Catalyst Factory) and mix evenly, add deionized water and knead, and extrude into a circumscribed circle with a diameter of 1.4 Millimeter trefoil strips, dried at 120°C for 4 hours and calcined at 600°C for 4 hours to obtain the catalyst carrier USY / Al 2 o 3 .

[0056] Weigh 0.952 g of Pd(NH 3 ) 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com