A wastewater treatment method for nitrogen and phosphorus removal

A waste water treatment, denitrification and phosphorus removal technology, applied in the direction of multi-stage water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc. The effect of small area, low cost and simple equipment maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

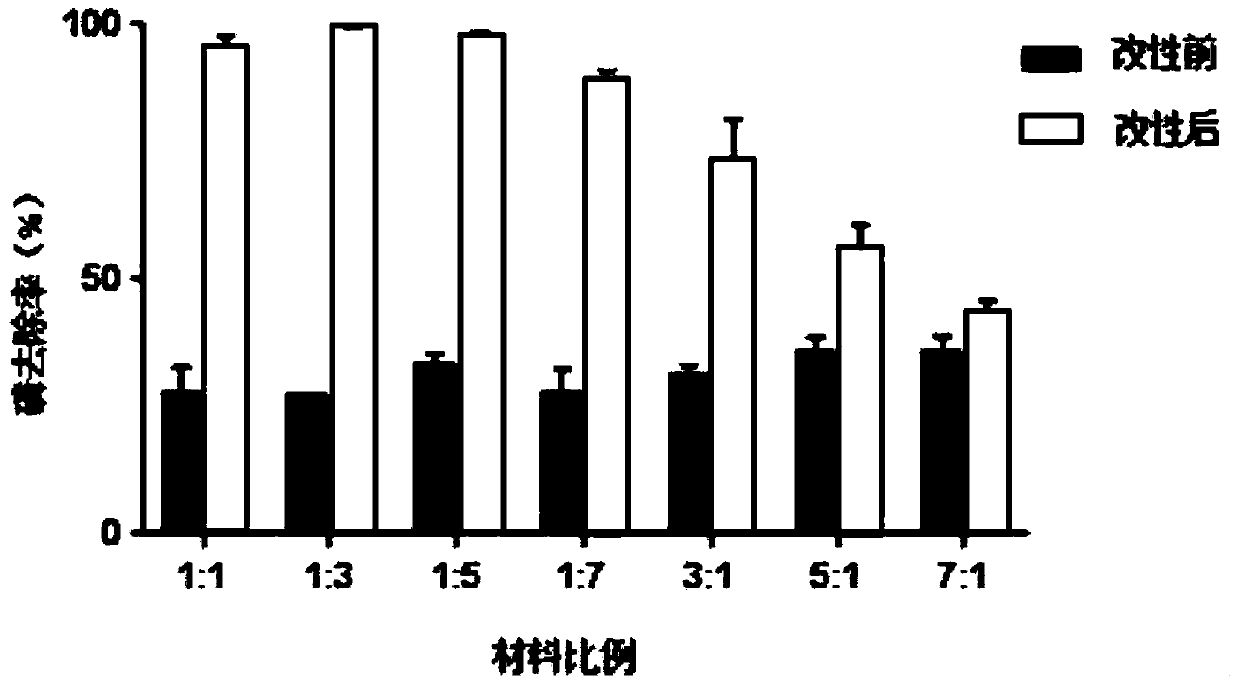

[0045] A preparation method for phosphorus removal adsorbent, specifically as follows:

[0046] Step 1. Mixing activated carbon and chitosan with a mass ratio of 1:a evenly to obtain an activated carbon-chitosan mixture, 1≤a≤7.

[0047] Step 2, adding the activated carbon-chitosan mixture of step 1 gained according to the solid-liquid ratio of 3 (g): 110 (ml) is dissolved in the acetic acid solution of 1.2% by volume concentration; Promptly obtains the absorption core stoste after dissolving completely.

[0048]Step 3, drop the adsorption core stock solution obtained in step 2 into the alkaline inorganic fixative solution drop by drop with a push needle of a micropump, and crystallize to obtain spherical granular adsorbent particles. The mass ratio of the adsorption core stock solution added to the alkaline inorganic fixative solution to the alkaline inorganic fixative solution is 1:25. The alkaline inorganic fixative is a mixed solution of absolute ethanol and aqueous sodium...

Embodiment 2

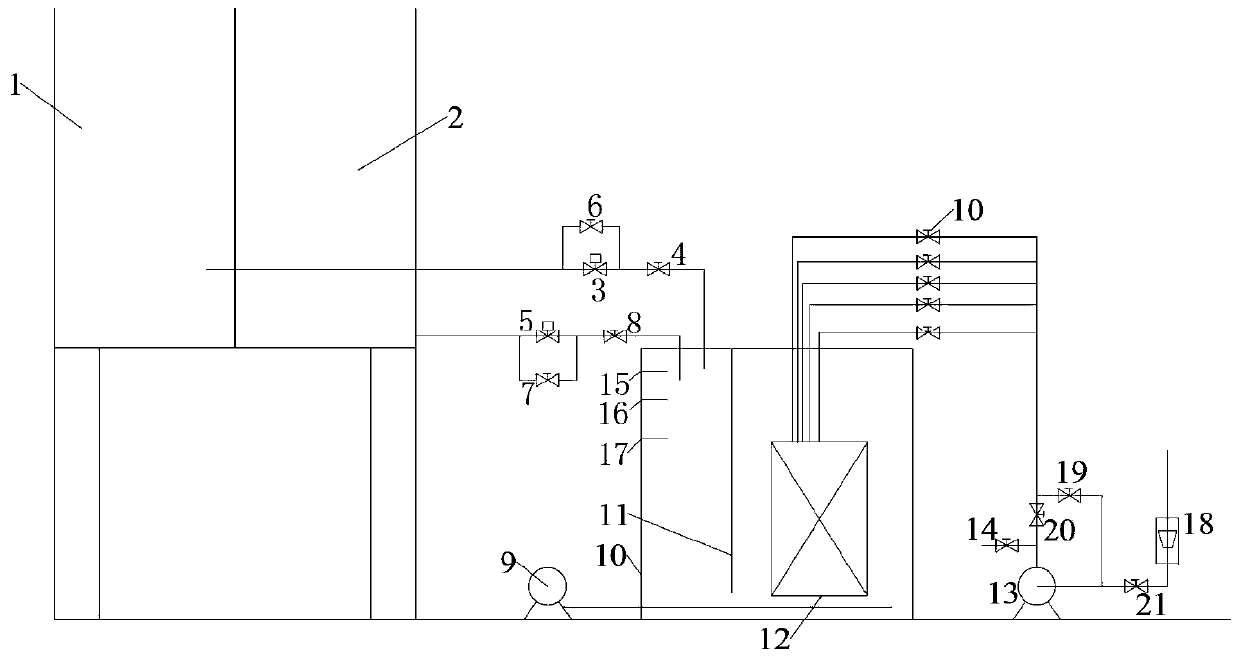

[0064] Such as figure 2 As shown, a nitrogen and phosphorus removal device includes a water inlet unit, a reaction unit and a water outlet unit arranged in sequence; the water inlet unit includes a first water tank 1, a first solenoid valve 3, a first on-off valve 4, a first manual Valve 6, the second water tank 2, the second solenoid valve 5, the second on-off valve 8 and the second manual valve 7. The water outlet at the bottom of the first water tank is connected with one end of the first electromagnetic valve 3 and the first manual valve 6 through a three-way pipe. The other ends of the first solenoid valve 3 and the first manual valve 6 are connected to one end of the first on-off valve 4 through a three-way pipe. The water outlet at the bottom of the second water tank is connected with one end of the second solenoid valve 5 and the second manual valve 7 through a three-way pipe. The other ends of the second solenoid valve 5 and the second manual valve 7 are connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com