Star-Delta Three-phase Induction Thermal Reactor

A triangular, induction heating technology, applied in the fields of chemical industry, food and environment, to achieve the effect of high temperature rise efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

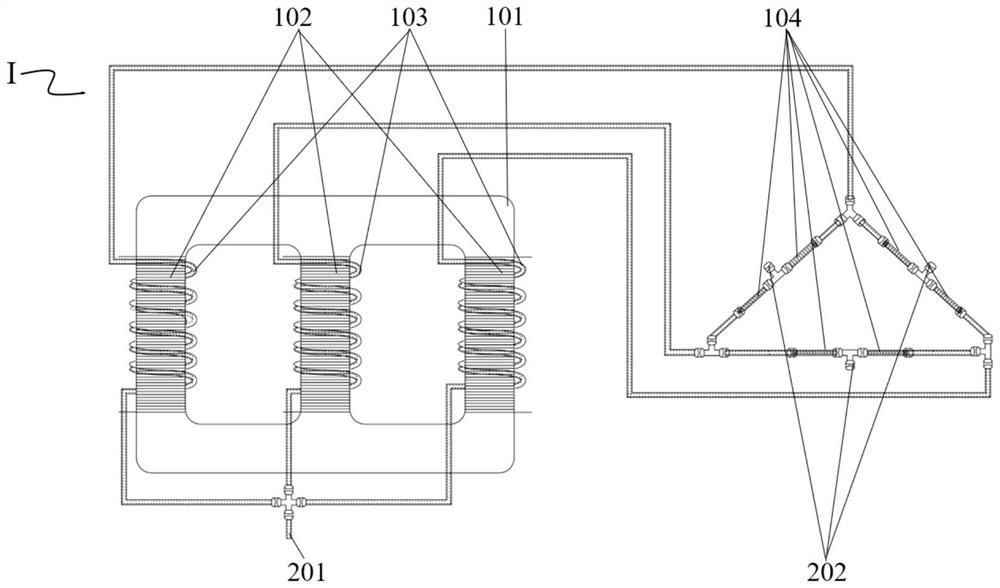

[0029] Star-delta three-phase induction thermal reactor I, such as figure 1 As shown, it includes a three-column magnetic circuit 101, an excitation coil 102, a magnetic coupling tube group 103, and a reaction chamber group 104; wherein, the magnetic coupling tube group 103 includes three magnetic coupling tubes and is connected in a star shape, and the reaction chamber group 104 Including three reaction chambers and connected in a delta; the connection between the magnetic coupling tube group 103 and the reaction chamber group 104 presents a three-phase circuit star-delta structure; the excitation coil 102 is wound on each iron core of the three-column magnetic circuit 101 On the column, the number of turns of the excitation coil 102 on each iron core column is 6 turns, and a three-phase power supply is used to apply an average voltage of 500V to the excitation coil 102, then the magnetic flux of each iron core column in the three-column magnetic circuit 101 is 0.06Wb, the ma...

Embodiment 2

[0035] Star-delta three-phase induction thermal reactor I, such as figure 1As shown, it includes a three-column magnetic circuit 101, an excitation coil 102, a magnetic coupling tube group 103, and a reaction chamber group 104; wherein, the three magnetic coupling tubes included in the magnetic coupling tube group 103 are connected in a star shape, and the reaction chamber group The three reaction chambers included in 104 are connected in a delta; the connection between the magnetic coupling tube group and the reaction chamber group presents a star-delta structure of a three-phase circuit;

[0036] The excitation coil 102 is wound on each iron core column of the three-column magnetic circuit 101. In the embodiment of the present invention, the number of turns of the excitation coil 102 on each iron core column is 12 turns, and a three-phase power supply is used to apply the excitation coil 102. With an average voltage of 2000V, the magnetic flux of each iron core column in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com