Domestic garbage incinerating technology

A technology of domestic waste incineration and domestic waste, applied in the direction of incinerator, combustion method, combustion type, etc., can solve the problems of black smoke, aggravate the difficulty and burden of disposal system, prevent air pollution, improve feeding efficiency, Effect of improving incineration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

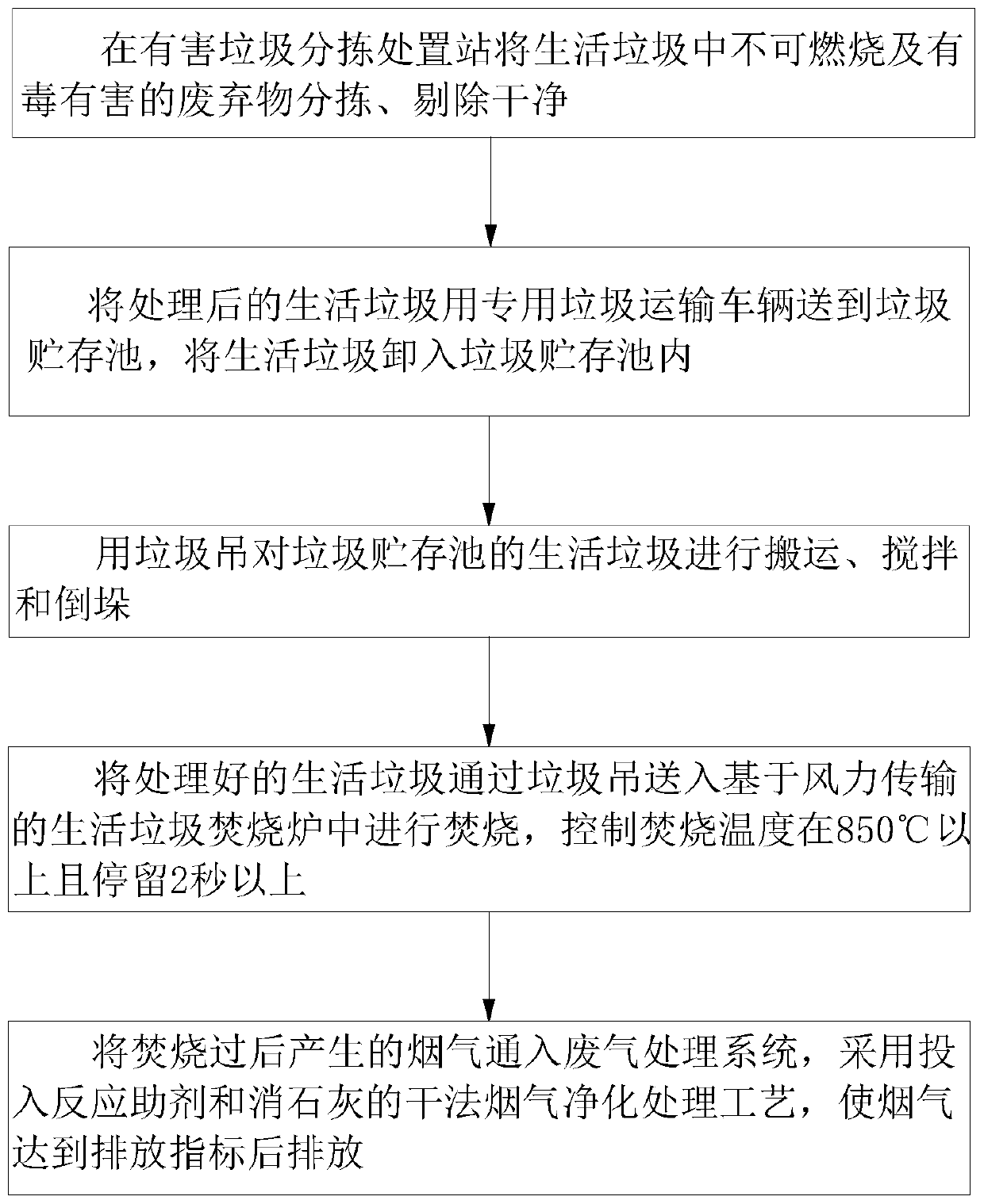

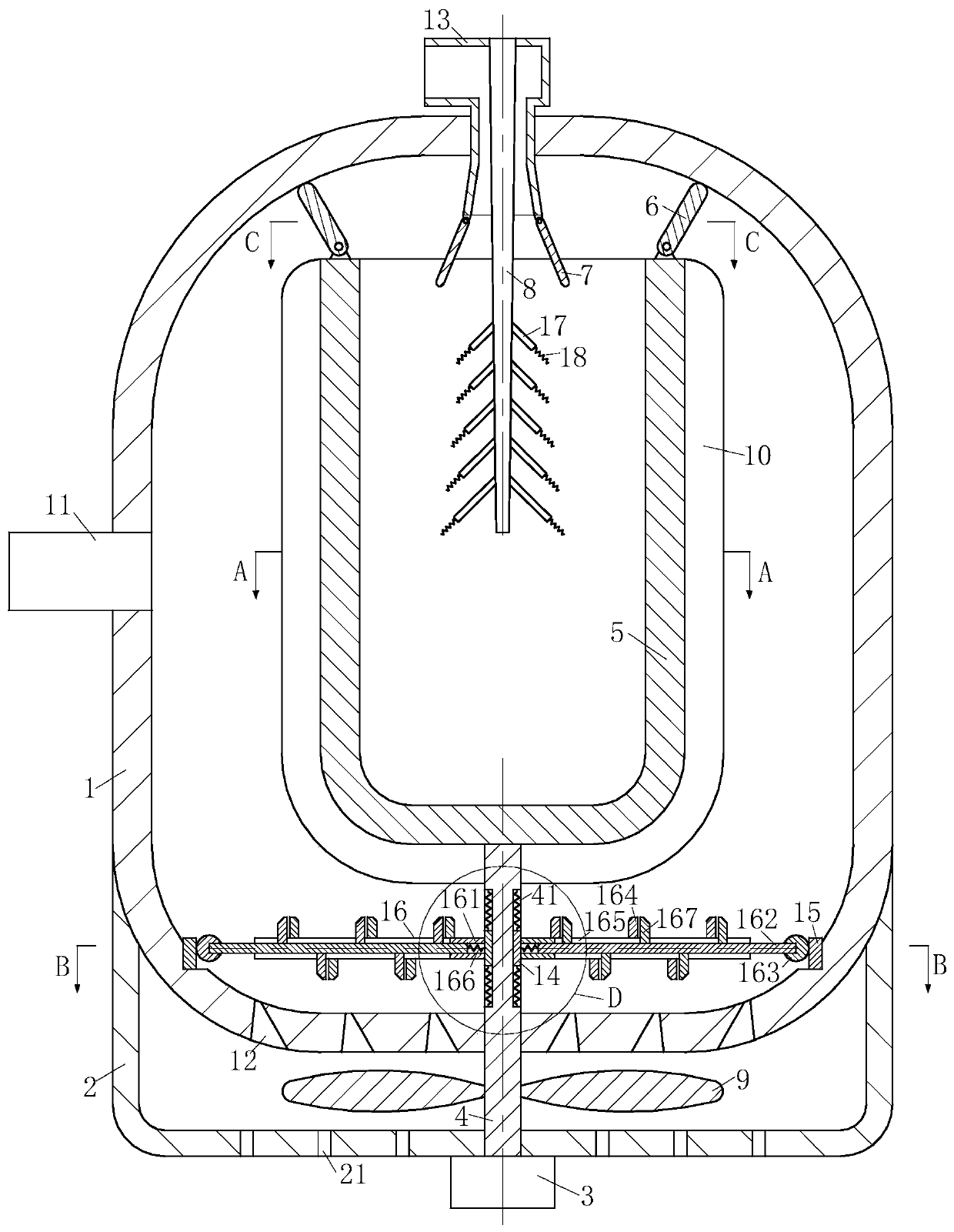

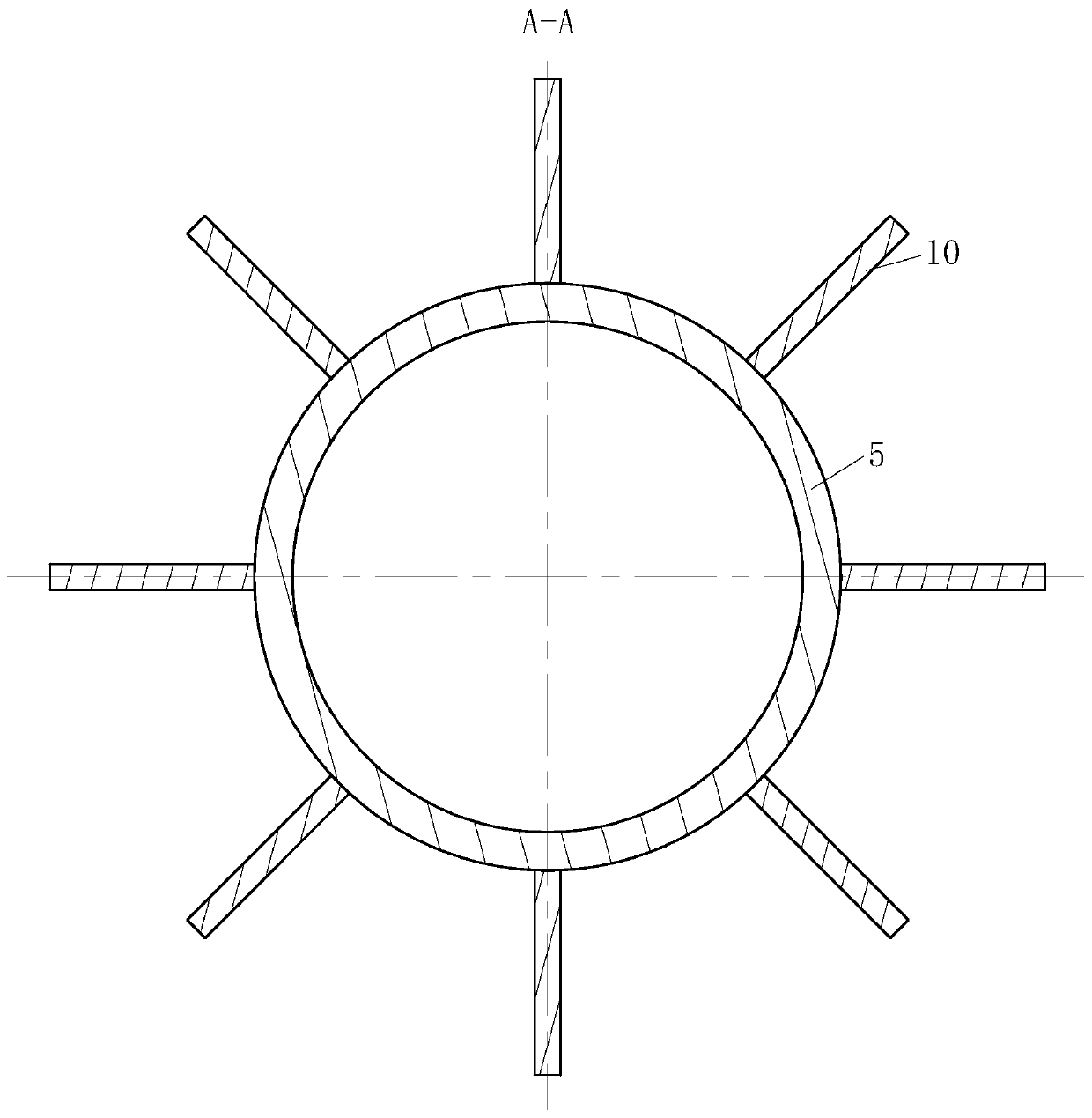

[0027] use Figure 1-Figure 6 A domestic waste incineration process of the present invention is described as follows.

[0028] Such as Figure 1-Figure 6 , a kind of domestic waste incineration process of the present invention, this process comprises the steps:

[0029] S1: At the hazardous waste sorting and disposal station, sort and remove non-combustible, toxic and harmful waste from domestic waste; ensure that domestic waste can be burned and will not cause harm to transport personnel;

[0030] S2: Send the household garbage processed in S1 to the garbage storage pool with a special garbage transport vehicle, and unload the household garbage into the garbage storage pool; ensure continuous feeding and improve the efficiency of domestic garbage processing;

[0031] S3: Use a garbage crane to carry, stir and invert the household garbage unloaded into the garbage storage pool in S2; ensure that the household garbage entering the furnace has a uniform composition and improve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com