Blast lamp suitable for VAD deposition

A blowtorch and lamp body technology, which is applied in the field of optical fiber manufacturing, can solve the problems of low germanium dioxide deposition efficiency, discontinuous raw material gas deposition flame, and cracking, and achieve the effects of reducing the probability of shedding, increasing density, and reducing cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

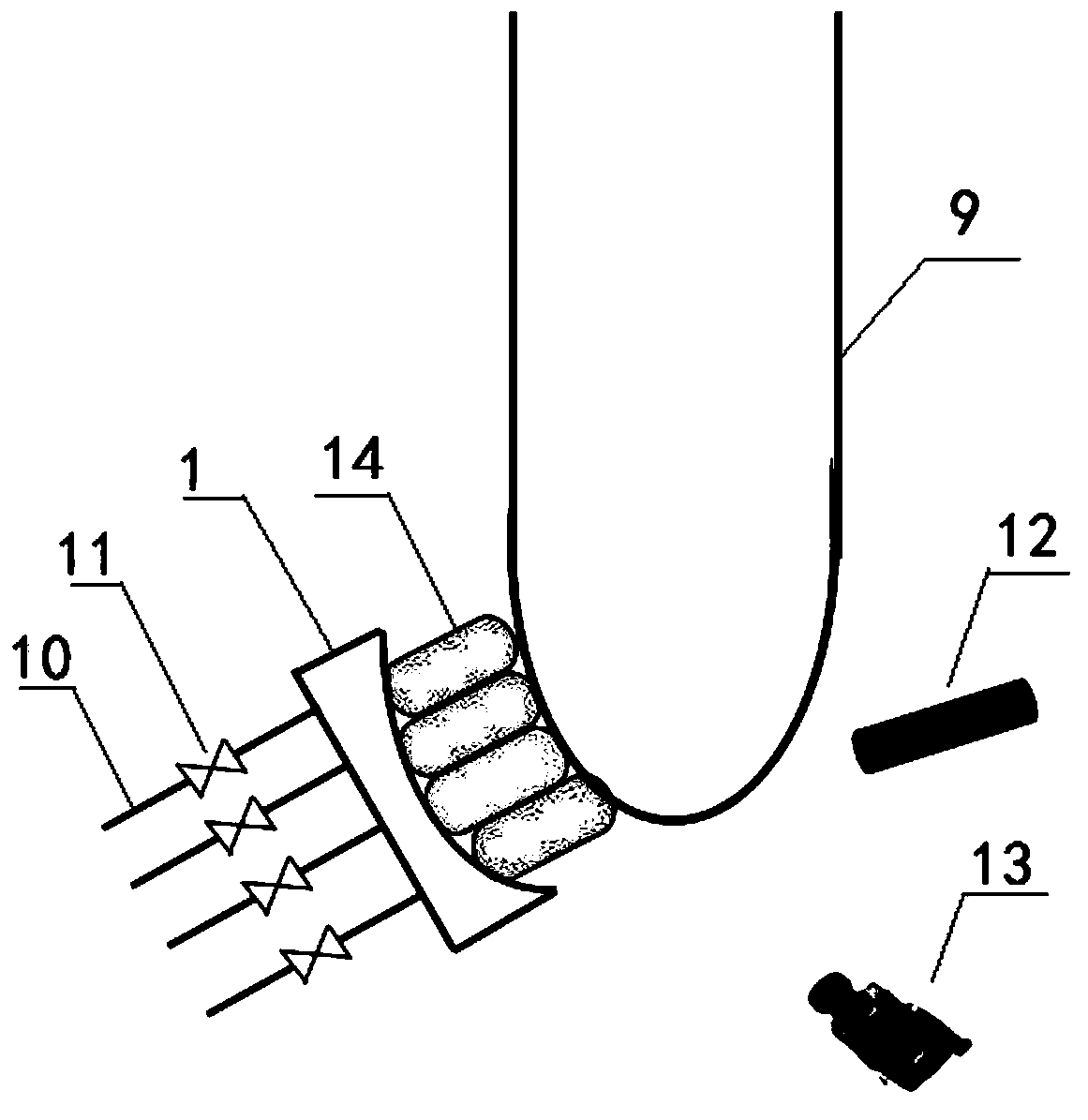

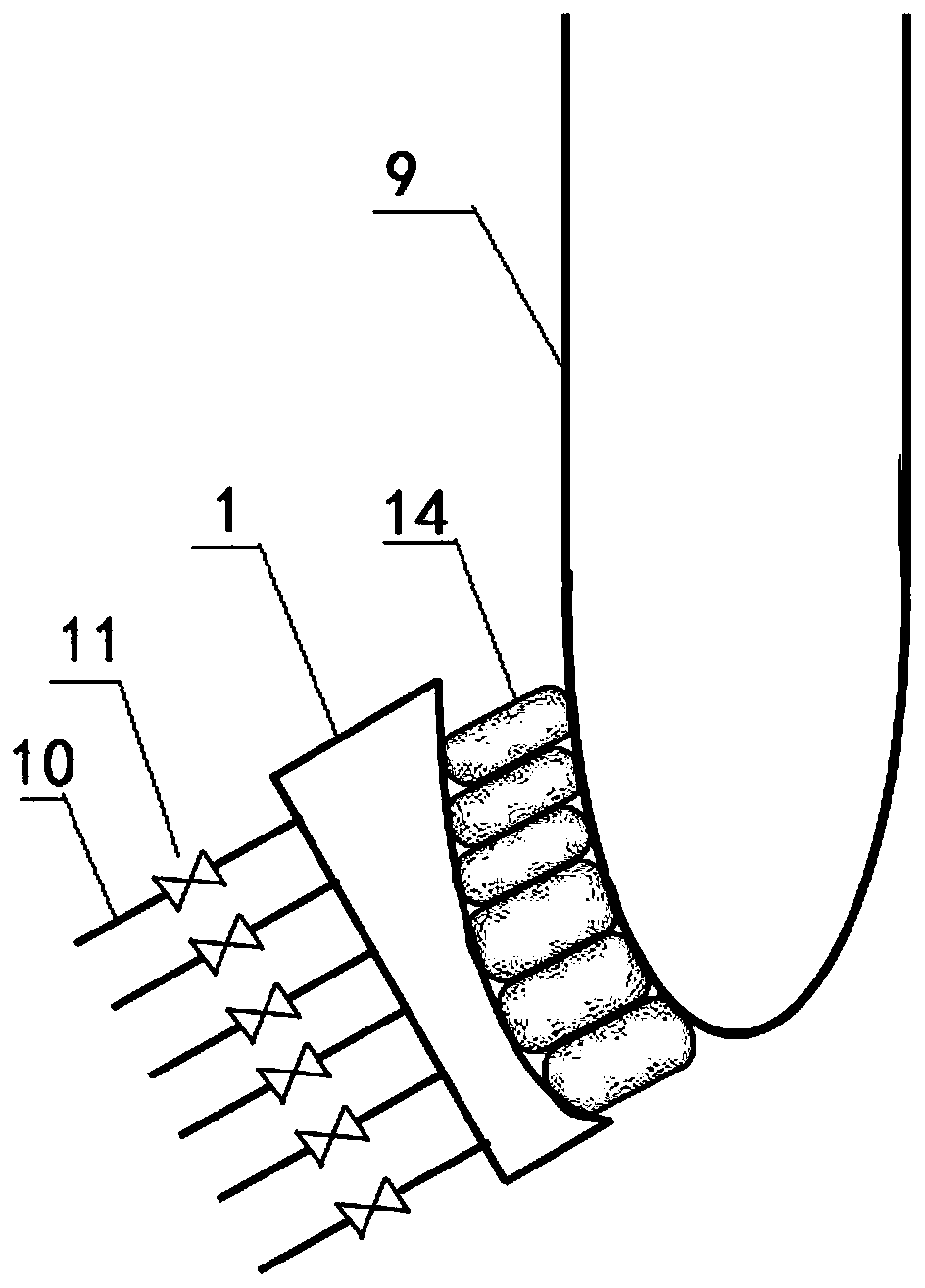

[0031] See figure 1 with figure 2 As shown, the embodiment of the present invention provides a blowtorch suitable for VAD deposition. The blowtorch includes a lamp body 1. The end surface of the lamp body 1 is provided with a feeding hole 2 and a multi-layer annular pore. The feeding hole 2 is In a straight-line structure, multiple annular air holes surround the outside of the feed hole 2.

[0032] See figure 2 As shown, the shape of the multi-layer annular air hole matches the shape of the feed hole 2. It can be understood that the multi-layer annular air hole is located on the outside of the feed hole 2 and is opened along the contour of the feed hole 2 and forms an annular hole. In this embodiment, the feed hole 2 is in a long strip shape, such as a rod shape, a rectangle, etc., and the multi-layer annular air hole is also in a strip shape in the overall structure. Specifically, the multi-layer annular pores include inner-layer isolation pores 3, inner-layer flame holes, out...

Embodiment 2

[0043] See figure 2 As shown, the embodiment of the present invention provides a torch suitable for VAD deposition. The difference between this embodiment and Embodiment 1 is that the inner flame hole includes a layer of inner layer hydrogen holes 4 and a layer of inner layer oxygen holes 5 The inner layer of hydrogen holes 4 is located inside the inner layer of oxygen holes 5; the outer layer of flame holes includes an outer layer of hydrogen holes 6 and an outer layer of oxygen holes 7, the outer layer of hydrogen holes 6 is located inside the outer layer of oxygen holes 7; The isolation air holes 3 and the outer isolation air holes 8 are also provided with one layer.

[0044] In this embodiment, the inner isolation pores 3 and the outer isolation pores 8 can also be divided into a plurality of branch holes, each branch hole is connected to an air inlet pipe 10 separately, and a flow regulating valve is arranged on the air inlet pipe 10 11.

[0045] See figure 2 As shown, the ...

Embodiment 3

[0047] See figure 1 As shown, the embodiment of the present invention provides a torch suitable for VAD deposition. The difference between this embodiment and Embodiment 1 is that the spray direction of each branch hole included in the feeding hole 2 is roughly the same as the deposition end surface of the powder rod 9 Vertical, when designing the direction of the branch holes, the two ends of the lamp body 1 facing away from the powder stick 9 and facing the powder stick 9 are called the back and the front respectively. All branch holes and the inner isolation pores 3 and the outer isolation pores 8 are A straight hole extending from the back to the front. Taking the branch hole in the middle of the feeding hole 2 as a reference, as the center line, the direction of the branch hole outside the center line in the feeding hole 2 is: when extending from the back to the front, it gradually approaches the center line to ensure the feeding Each supporting hole of the hole 2 is subst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com